Accelerating pulse forming device of dielectric wall accelerator

A technology for accelerating pulses and accelerators, which is applied in the direction of linear accelerators, accelerators, electrical components, etc., can solve problems such as increased manufacturing costs of accelerators, limitations in the width of accelerated particle beams, and high technical difficulties, achieving stable and reliable operation, saving photoconductive switches, Laser saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

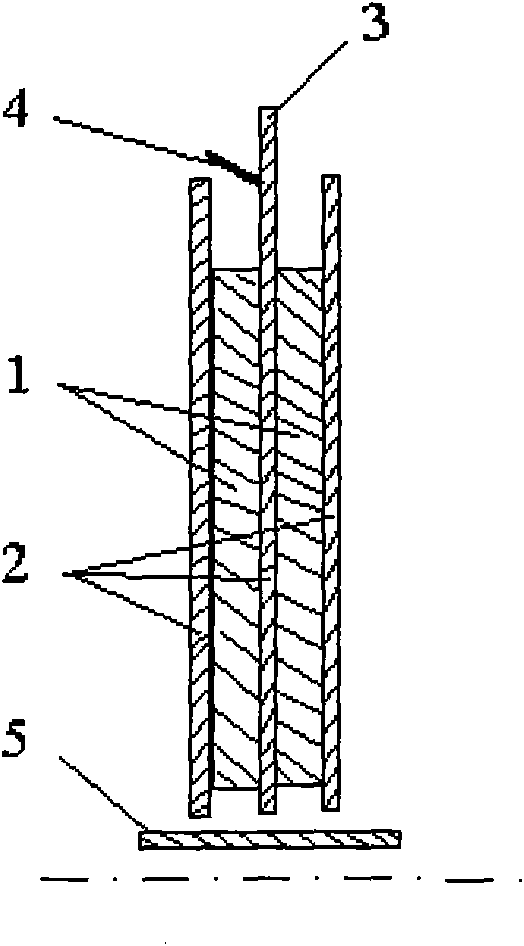

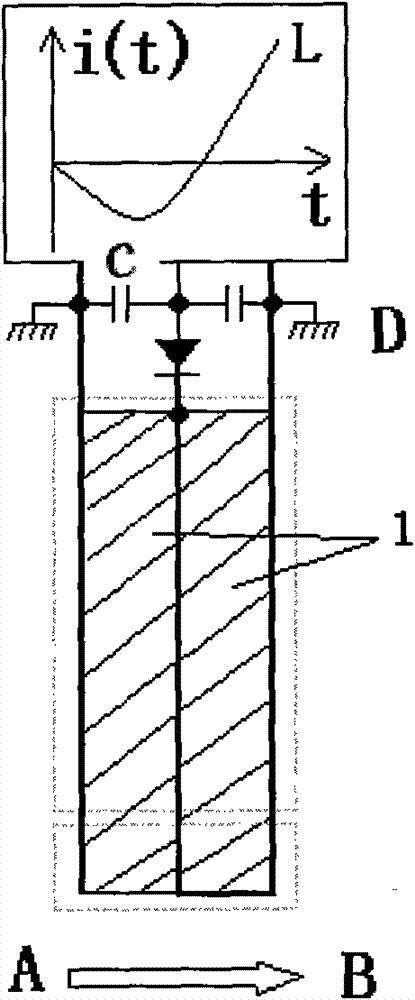

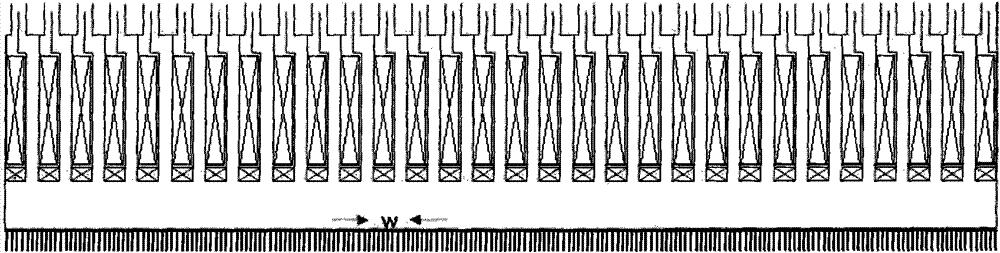

[0035] Examples of the present invention Figure 4 As shown: the accelerating pulse forming device of the dielectric wall accelerator includes three functional sections, the first functional section is the accelerating voltage pulse forming part, which consists of a dielectric plate 1, a metal electrode 2 clothed on both sides of the dielectric plate 1, and an external connection cloth in the middle of the dielectric plate 1. The power supply electrode 3 is composed of a photoconductive switch 4 between the external power supply electrode 3 and the ground electrode of the metal electrode 2; the second functional section is a matching section, and the accelerating voltage pulse forming part and the matching section use the same dielectric plate 1, and the external power supply Electrode 3 ends at the end of the accelerating voltage pulse forming part, the high-voltage electrode of the corresponding matching section is connected to the high-voltage electrode of the accelerating v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com