Catalyst foils and methods and apparatus for the insertion of foils into catalytic reactors

A technology for inserting equipment and catalysts, applied in chemical instruments and methods, chemical/physical/physical-chemical stationary reactors, chemical/physical/physical-chemical processes, etc., which can solve the problems of high abrasiveness and difficult operation of foils

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

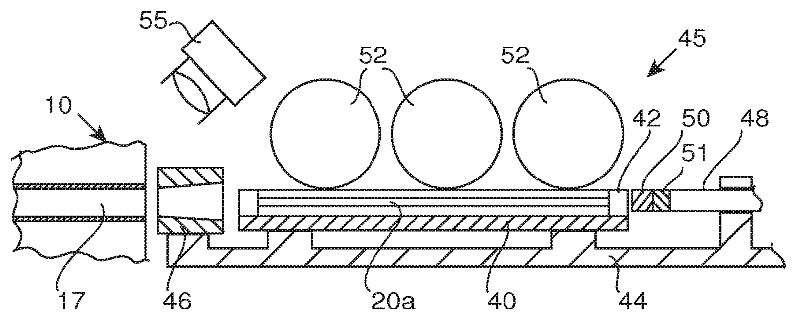

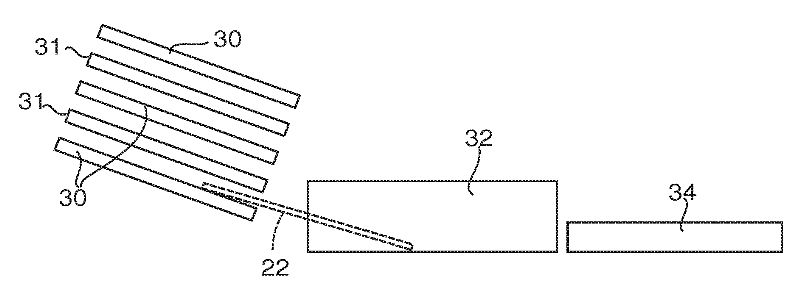

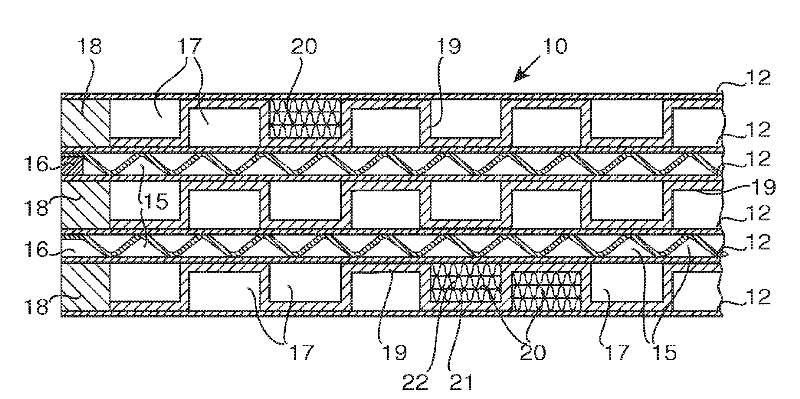

[0031] refer to figure 1, shows a reactor block 10 suitable for performing the Fischer-Tropsch synthesis, the reactor block 10 being only partially shown in cross-section. The reactor block 10 consists of a stack of 1 mm thick flat plates 12 spaced apart to alternately define channels 15 for the coolant fluid and channels 17 for the Fischer-Tropsch synthesis. The coolant channels 15 are also defined by a 0.75 mm thick sheet 14 formed in a flat-topped sawtooth configuration and solid edge strips 16 . The channel 17 for the Fischer-Tropsch synthesis is sealed by a solid edge rod 18 and is also defined by a 1.0 mm thick sheet 19 formed into a castellation with a height typically in the range 4mm to 12mm, eg 5mm. In one embodiment, the resulting channel 17 is 10 mm wide, 5 mm high, and runs straight through the stack from one face to the opposite face. In each channel 17 for the Fischer-Tropsch synthesis, a catalyst insert 20 is provided. For example, the insert 20 may comprise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com