Method for producing connecting elements by way of a pressure welding process and connecting element

A technology for connecting components and manufacturing connections, which is applied in the direction of welding/welding/cutting objects, connections, manufacturing tools, etc., which can solve the problems of long delivery time and early lead time, and achieve high manufacturing flexibility and increase the effect of quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

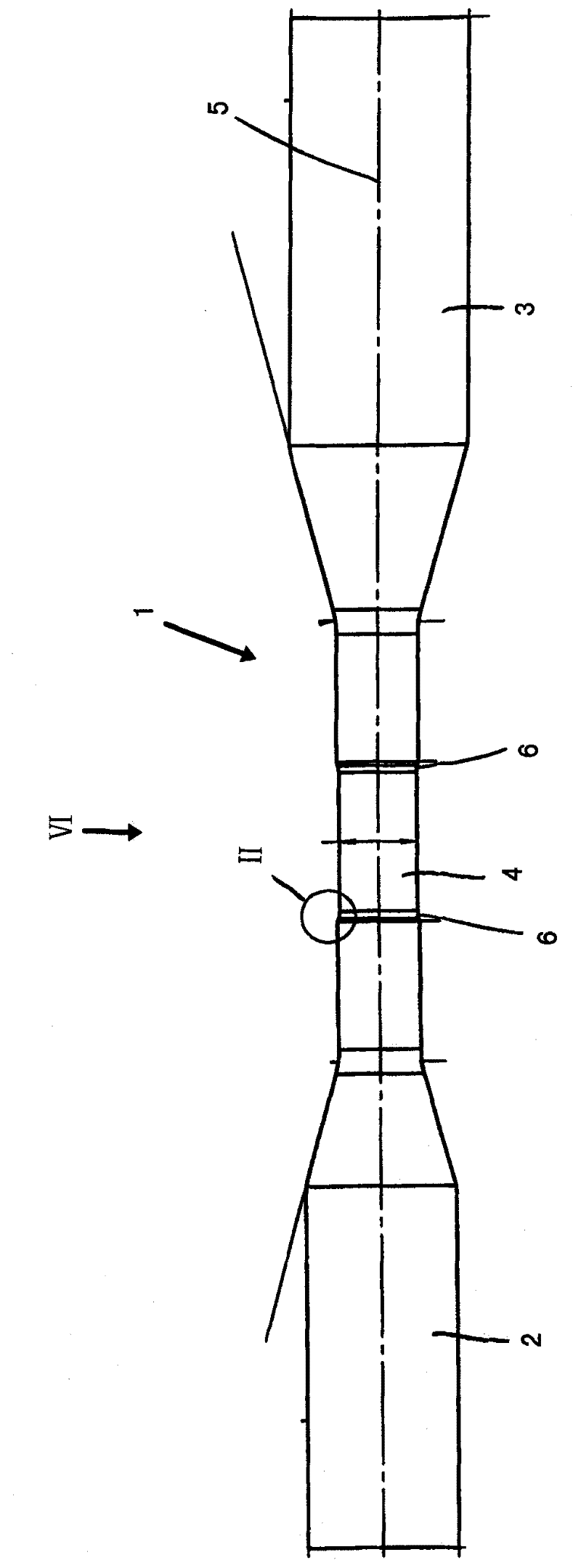

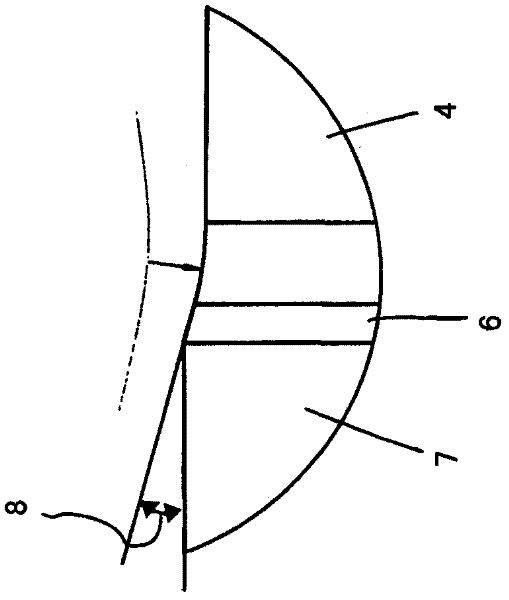

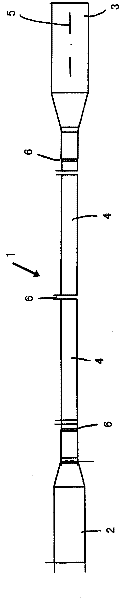

[0025] according to figure 1 In the embodiment, the connection element (1) consists of ends (2, 3) and a spacer element (4). The ends (2, 3) and the spacer element (4) are arranged one behind the other in the direction of the longitudinal axis (5). In the region of the ends of the terminals ( 2 , 3 ) facing the spacer element ( 4 ), welds ( 6 ), which connect the spacer elements ( 4 ) to the terminal pieces ( 2 , 3 ), are arranged in each case. . The spacer element ( 4 ) can be configured, for example, as a rod-shaped structural element. However, it is also possible for the spacer element to be configured as a plate or as a profiled part.

[0026] The weld (6) is typically made by pressure welding. Depending on the respective requirements of the manufacturing process to be carried out and the requirements of the connection element ( 1 ) to be welded, different welding methods can be used. Consider friction welding, for example, which can be implemented not only as rotatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com