Device for sealing a bearing lubricated with a liquid lubricant

A technology of bearing components and lubricants, which is applied to the sealing of bearing components, shafts and bearings, engines, etc., can solve the problems of bearing configuration leakage, liquid lubricant blockage, etc., and achieve the design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

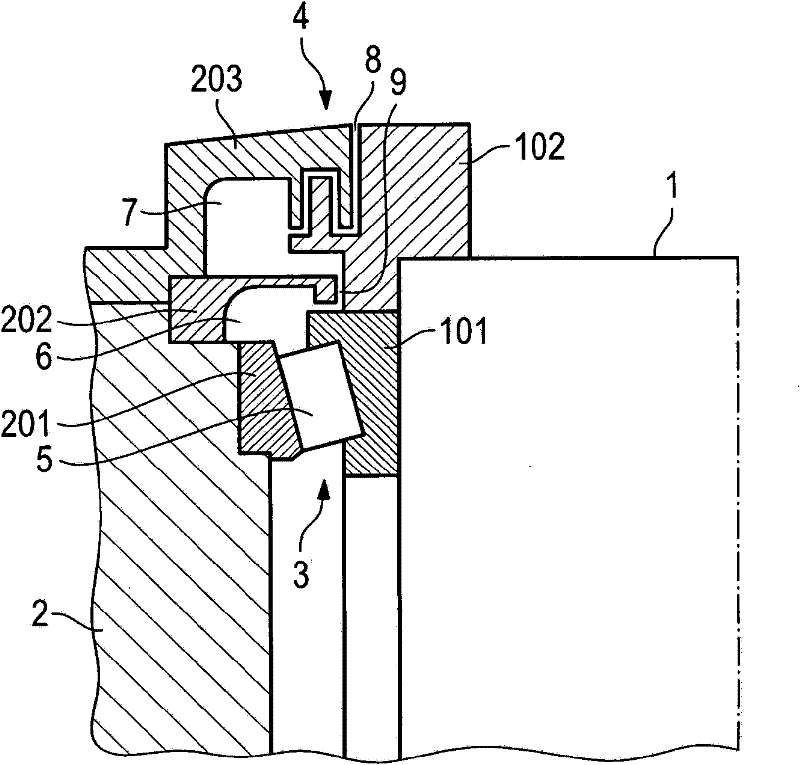

[0038] figure 1 Shown is the rotating part 1 within a non-rotating housing 2 . Correspondingly, rotating parts are denoted by reference numerals starting with 1, and non-rotating parts are denoted by reference numerals starting with 2.

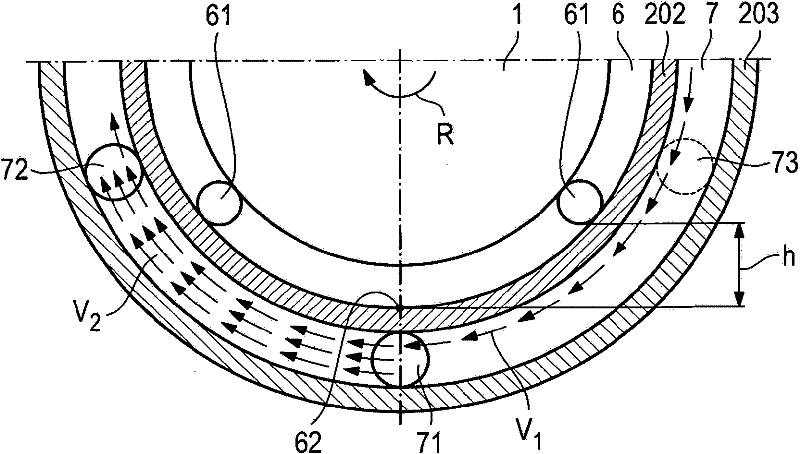

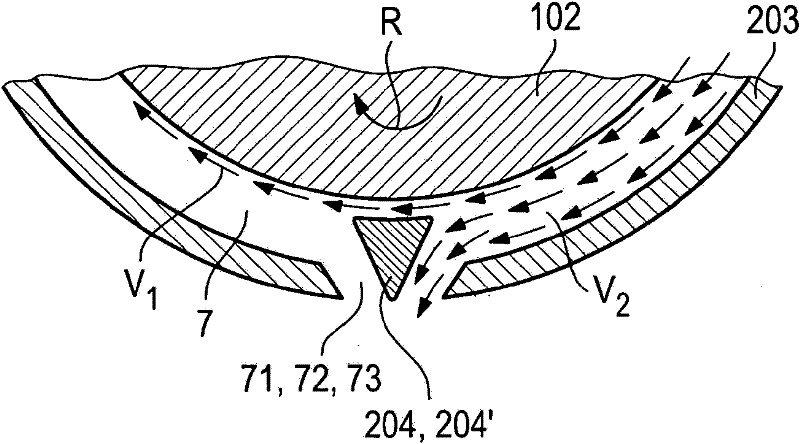

[0039] The rotating part 1 is the shaft in the drive system and is of relatively large diameter, typically greater than 300 mm. The rotating part rotates relatively quickly, so that a peripheral speed greater than or much greater than 30 m / s is developed on the outer circumference of the shaft. In addition to the rotating part 1 , the bearing housing 101 , which is here the bearing housing 101 of the bearing 3 like a tapered roller bearing, also rotates. The bearing 3 is designed with a seat (not shown) in a so-called X configuration and mounts the rotating part 1 . Together with the bearing housing 101 and the rotating part 1 , the rotating labyrinth sealing ring 102 also rotates as part of the device 4 for sealing the bearing 3 . In addi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com