Secondary impurity cleaning device

A cleaning device and residual technology, applied in threshing equipment, applications, agricultural machinery and tools, etc., can solve the problems of reduced cleaning performance, increased grain damage, uneven distribution, etc., to improve cleaning and screening performance, improve Excellent cleaning performance, convenient disassembly and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

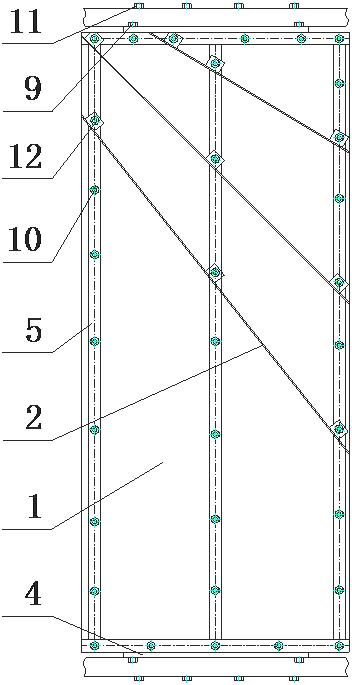

[0013] In order to make the technical means and innovative features of the present invention achieve the goals and effects easily understood, the present invention will be further described below in conjunction with specific embodiments and illustrations.

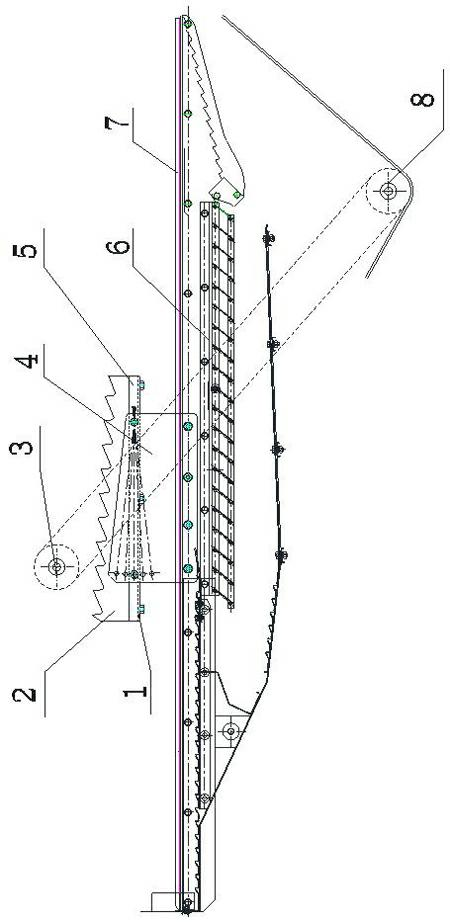

[0014] Such as figure 1 Shown, a kind of secondary trash cleaning device of harvesting machine, comprises secondary trash cleaning screen 1, secondary trash cleaning screen frame 5, connecting support plate 4, and zigzag guide plate 2, secondary trash cleaning device is installed on Between the upper sieve 6 and the discharge port 3 of the miscellaneous auger. The residuals such as broken ears, grains and short stalks collected by the residual auger 8 are transported to the discharge port 3 of the residual auger through the auger, and this part of the residual is sprayed on the secondary residual cleaning screen 1.

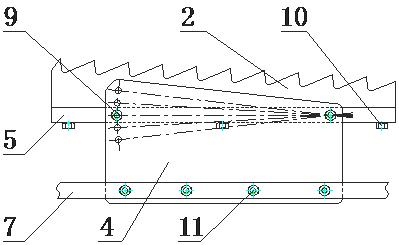

[0015] Such as figure 2 As shown, the secondary trash cleaning screen 1 is installed on the secondary tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com