Cooling device used for vacuum forming machine

A vacuum forming machine and cooling device technology, applied in the field of home appliance equipment molds, can solve the problems of long cooling time, reduced production efficiency, insufficient cooling, etc., and achieve the effect of accelerated cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

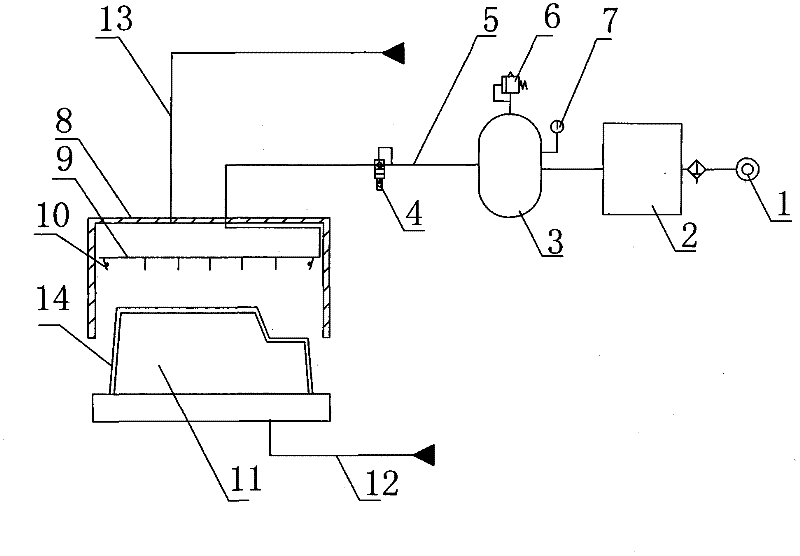

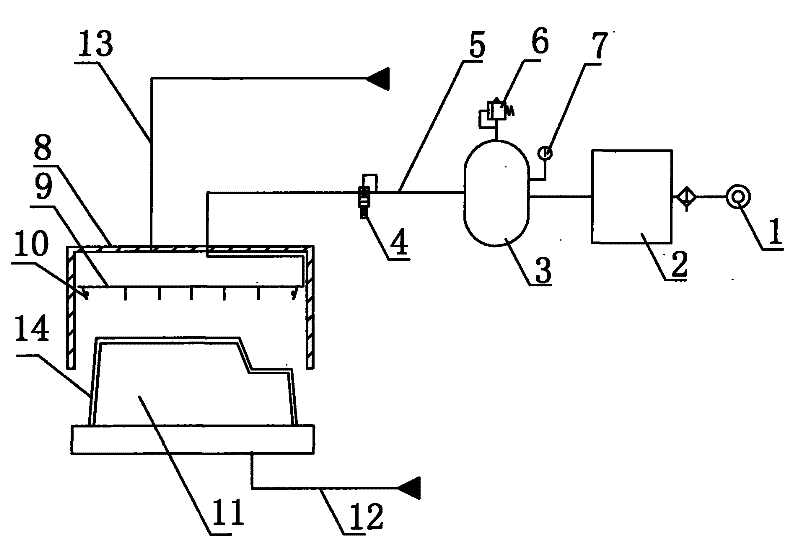

[0013] The present invention will be further described below with reference to the accompanying drawings and embodiments.

[0014] As shown in the accompanying drawings, the cooling device for the vacuum forming machine in this embodiment includes an air cooler 2, an air storage tank 3, an air supply pipe 5, an electronically controlled valve 4 arranged on the air supply pipe, and the air outlet of the air cooler 2 is connected to the The inner cavity of the air storage tank 3 is communicated, and the air storage tank 3 is communicated with the inner cavity of the sealing box 8 of the vacuum forming machine through the air supply pipeline 5 . In this embodiment, an annular pipe 9 is also arranged in the sealing box. The annular pipe 9 communicates with the air supply pipe 5. The annular pipe 9 is arranged along the inner wall of the sealing box 8 in a circle, that is, the annular pipe is rectangular and sealed The cross-sectional shape of the box 8 is the same, and a number of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap