Device used for producing three-component skin core type fiber

A sheath-core, three-component technology, which is applied in fiber processing, filament/thread forming, textiles and papermaking, and can solve the problems of rare research on three-component sheath-core composite spinning components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

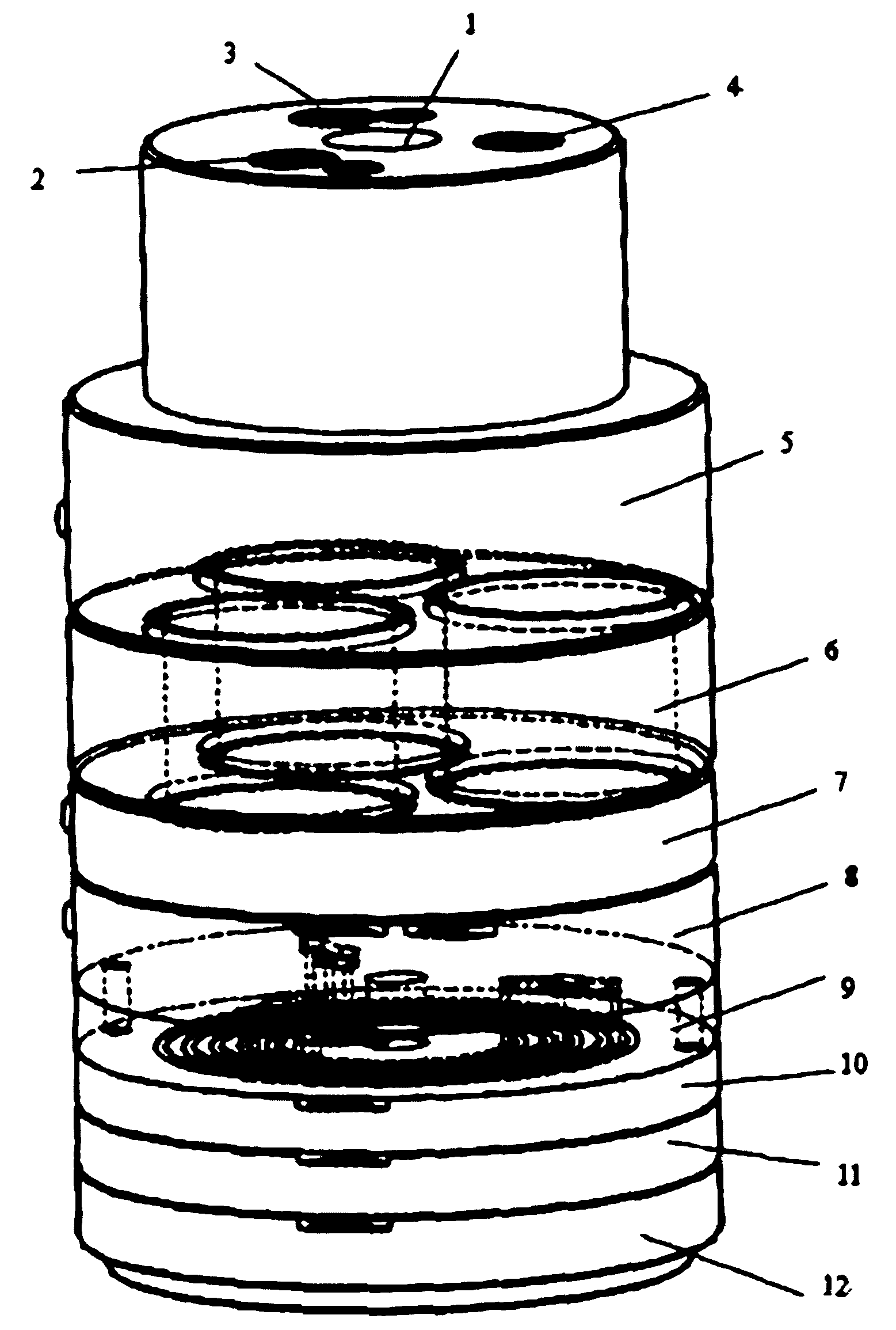

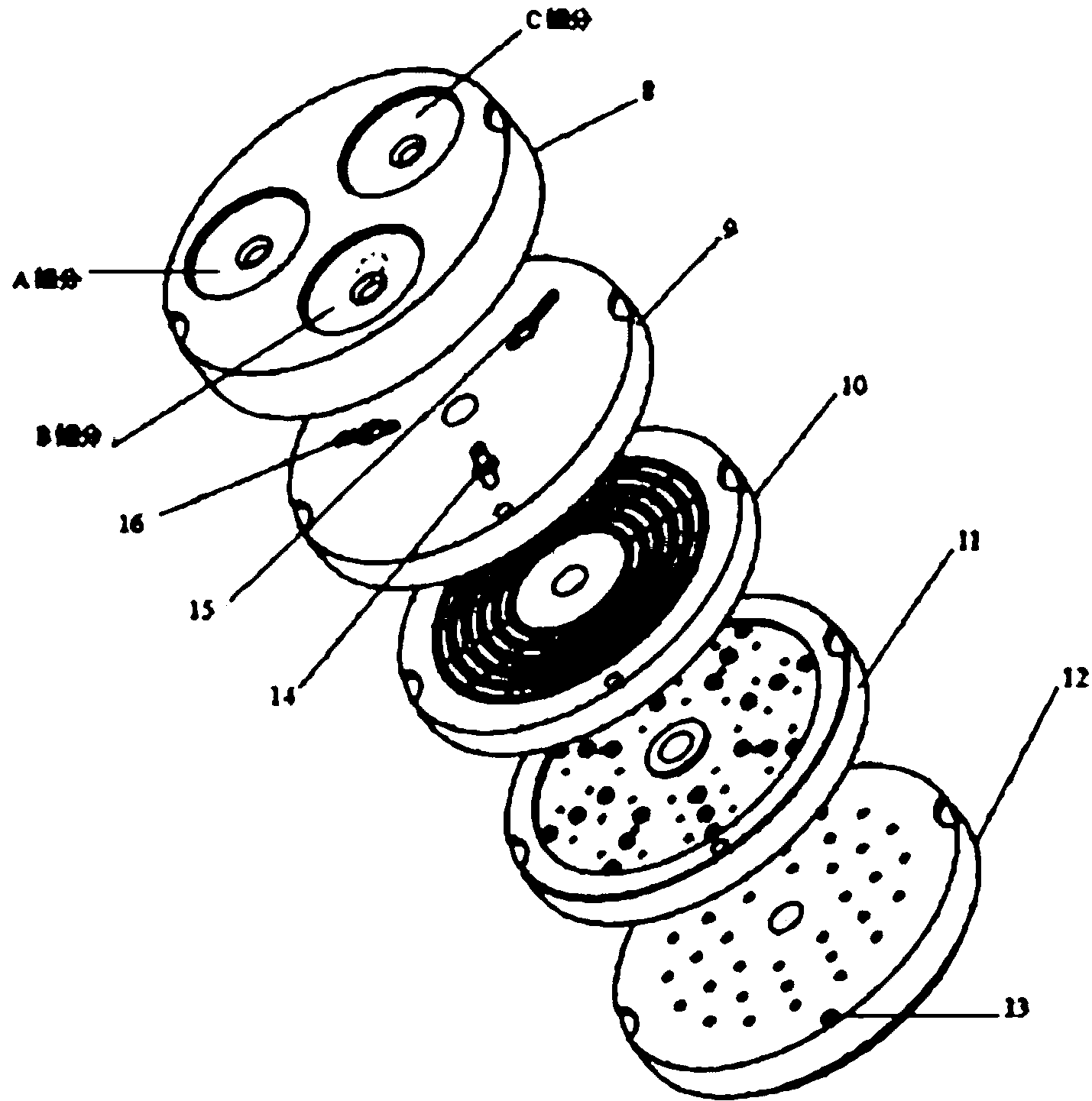

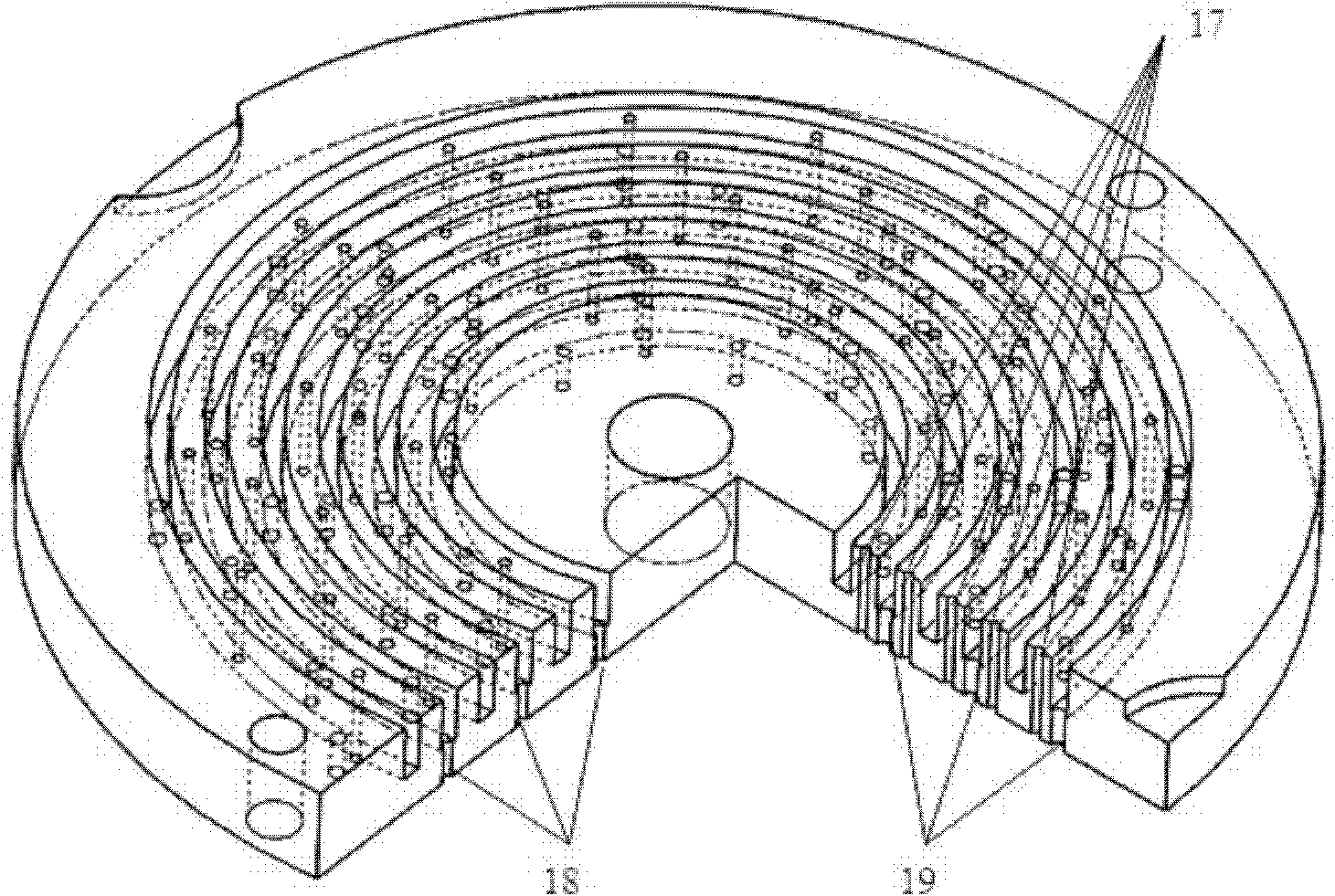

[0015] Such as Figure 1-4 As shown, a device for producing three-component sheath-core fibers includes a hole 1, a first inlet 2, a second inlet 3, a third inlet 4, a gland 5, a first inner sand cup 6, a second Inner sand cup 7, first distribution plate 8, second distribution plate 9, third distribution plate 10, fourth distribution plate 11, spinneret plate 12, positioning pin hole 13, first melt distribution groove 14, second melting body distribution groove 15, the third melt distribution groove 16, the first guide hole 17, the second guide hole 18, the third guide hole 19, the first guide hole 20, the second guide hole 21, the pressure The cover 5, the first inner sand cup 6, the second inner sand cup 7, the first distribution plate 8, the second distribution plate 9, the third distribution plate 10, the fourth distribution plate 11 and the spinneret plate 12 are sequentially connected and fixed. The hole 1 at the center of the cover 5 is connected to the spinning box, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com