Ultrasonic disk motor with clutch and displacement amplification mechanism and working method thereof

A displacement amplification mechanism, ultrasonic motor technology, applied in the direction of generators/motors, electrical components, piezoelectric effect/electrostrictive or magnetostrictive motors, etc., can solve the problem of low-speed and ultra-low-speed operation and small thrust , large loss and other problems, to achieve the effect of small working loss, improved displacement stroke and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

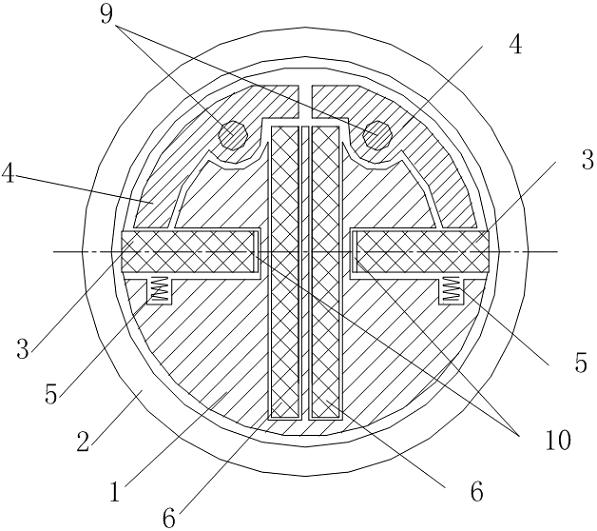

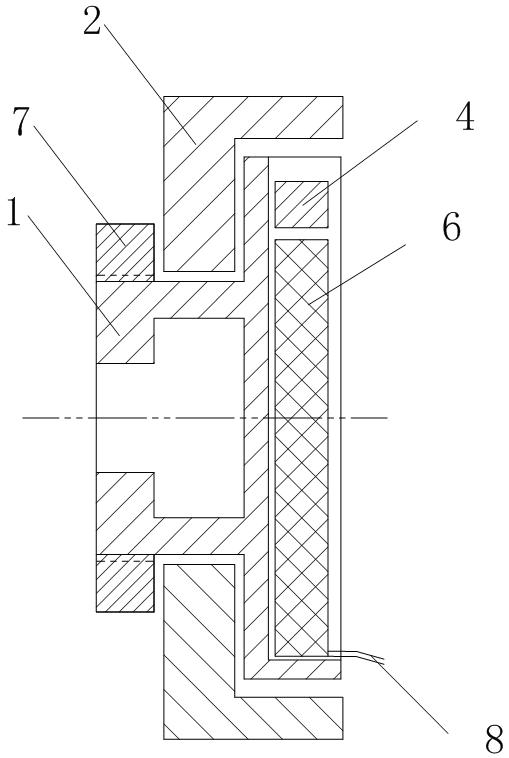

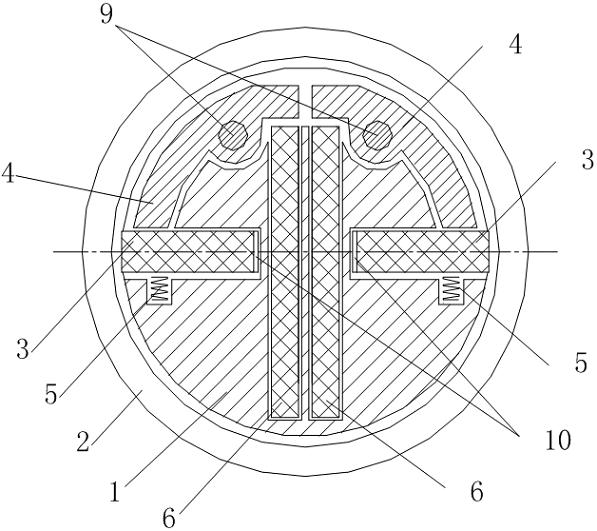

[0041] Such as figure 1 and 2 As shown, the present invention is mainly composed of a stator 1 with a disc-shaped structure, and a disc-shaped rotor 2 that is sleeved on the outer wall of the stator 1 and forms a sliding fit. The outer wall of the stator 1 is provided with a stator end cover 7 for The rotor 2 is limited so that it cannot move axially; one end surface of the stator 1 is provided with a clutch piezoelectric strip groove extending to the inner wall of the rotor 2, and the side walls of the clutch piezoelectric strip groove are respectively It is connected with the opposite rotation arm groove and spring groove, that is, the rotation arm groove and the spring groove are preferentially separated by 180° on the side wall circumference of the clutch piezoelectric strip groove, so as to better reset Effect, the relative position of the rotating arm groove and the spring groove in the present invention is not limited to this, as long as the position is substantially o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com