Coating blow dryer

A blow dryer and coating technology, which is applied in the direction of coating, liquid coating device on the surface, surface pretreatment, etc., can solve the problems of variable unevenness and odor of steel wire oil, and achieve quality improvement and coating even layer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

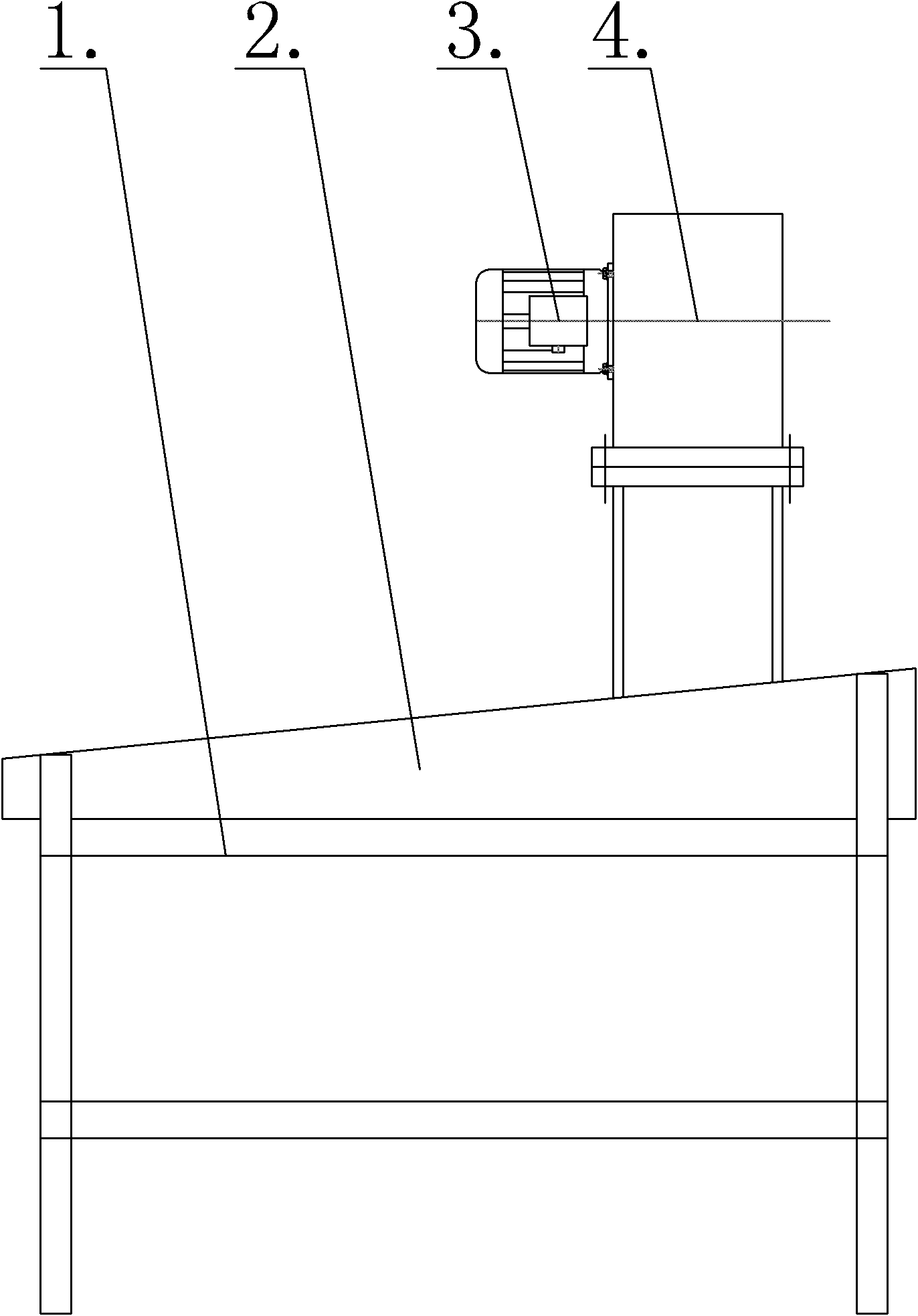

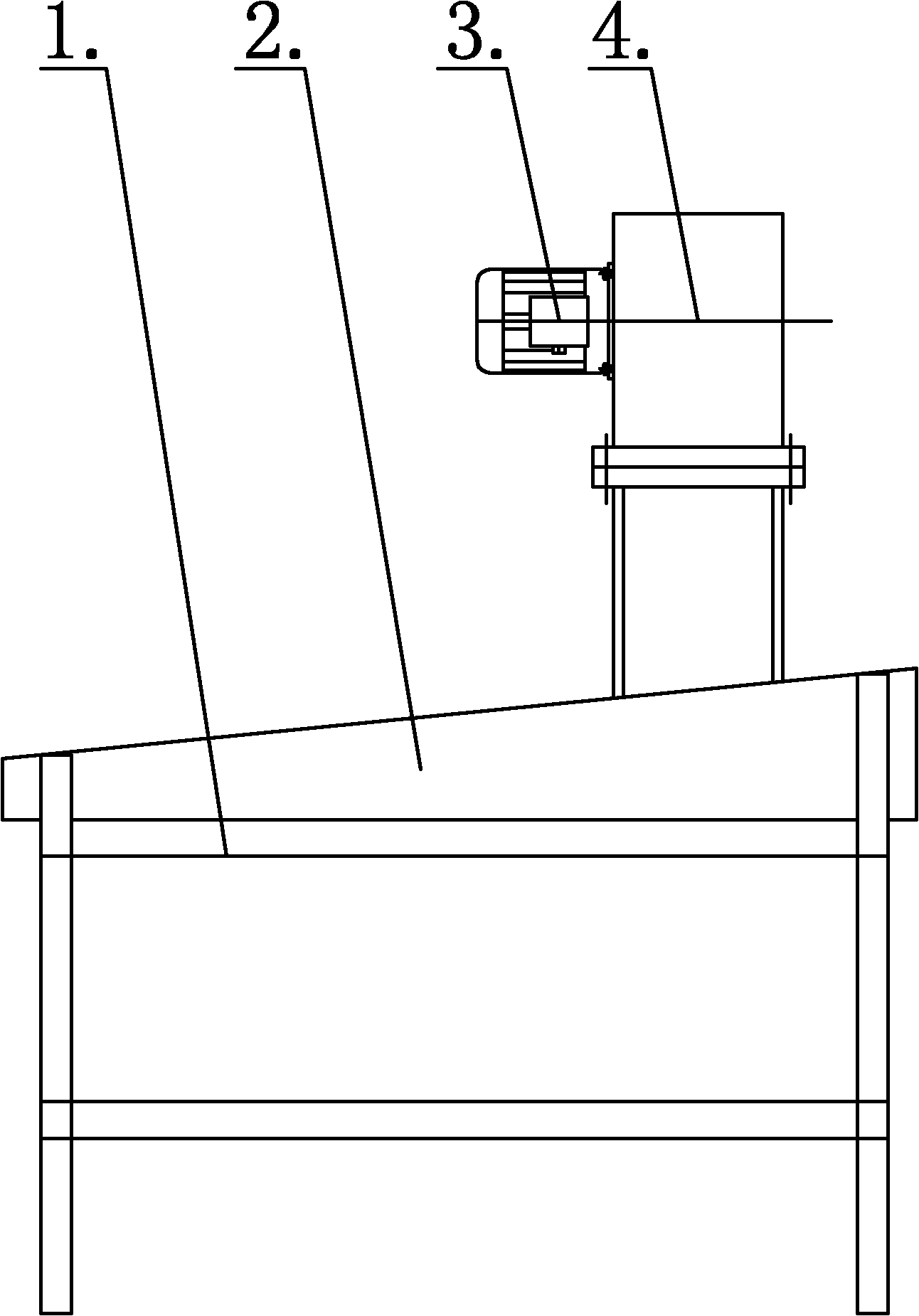

[0009] Such as figure 1 , 2, the present invention is provided with bellows 2 on the top of support 1, fan 4 is arranged above one end of bellows 2, motor 3 and fan 4 are connected together through output shaft, two air outlet ends of described bellows 2 are set One end is low and the other end is high.

[0010] Through above setting, when the present invention works, under the effect of motor 3, blower fan 4 will be blown in the bellows 2, thereby the coating of the steel wire in the bellows 2 is blown dry very soon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com