Novel heat concentrating and energy saving device of plastic extruding machine

An energy-saving device and extruder technology, which is applied in the field of injection molding machines and rubber extruders, can solve the problems of greatly affecting the working efficiency of extruders, the reduction of screw heating temperature and torque, and uneven thermal efficiency, so as to shorten the heat radiation Distance, improve thermal efficiency, fast heat dissipation effect

Inactive Publication Date: 2011-10-12

钱慧萍

View PDF4 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, the fillers of injection molding machines and rubber extruders are heated and melted, and there are uneven thermal efficiencies. Excessively high heating temperature of the screw leads to reduced torque, weakened strength, slow heat dissipation of the mechanical maintenance screw, etc., which have a great impact on the working efficiency of the extruder.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

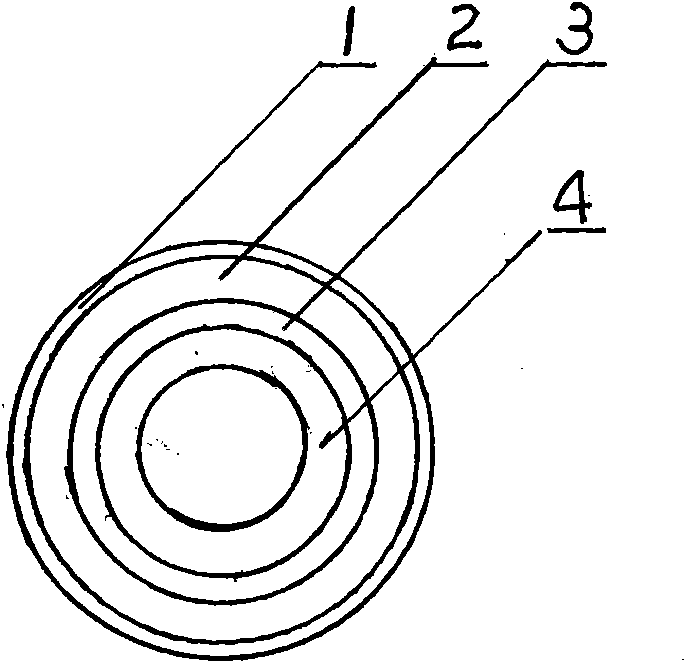

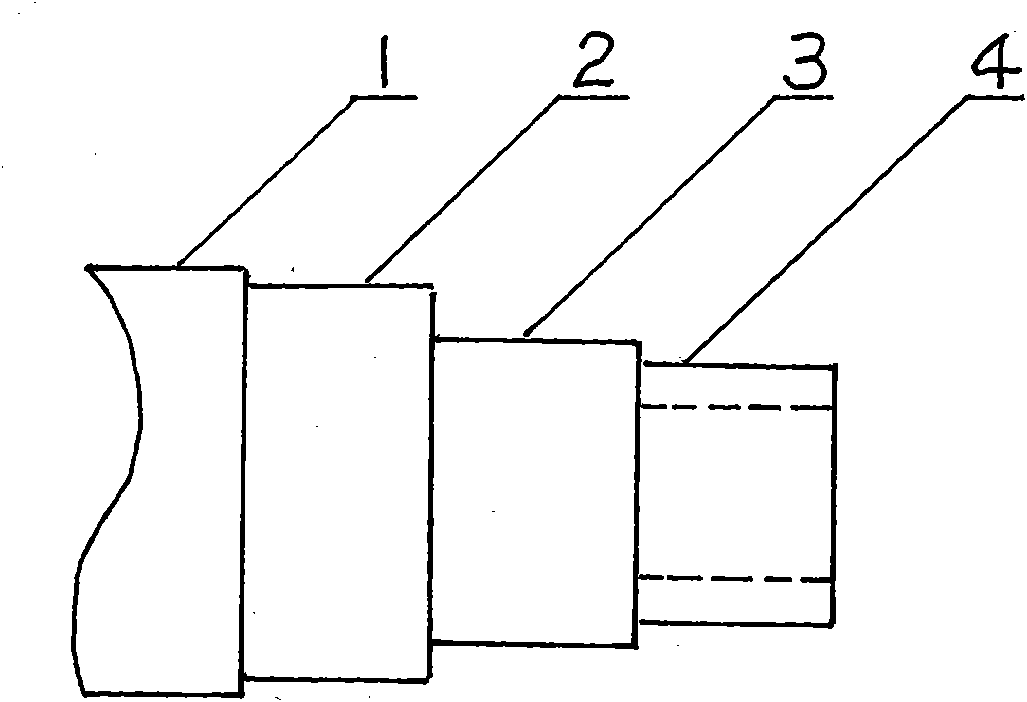

[0011] in the attached figure 1 And attached figure 2 In the shown embodiment, in the barrel (1), the screw (2) of the plastic extruder is hollowed out into a hollow shaft (3). A heat insulation cylinder (4) is arranged inside the hollow shaft (3) to be structurally connected with the hollow shaft (3). Hollow out the center of the heat insulation cylinder (4).

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a novel heat concentrating and energy saving device of a plastic extruding machine. In the device, a screw rod of the plastic extruding machine is engraved to form a hollow shaft in a material barrel, and a heat insulating barrel is arranged in the hollow shaft and is connected with the hollow shaft structure. The center of the heat insulating barrel is engraved, and the distance for radiating heat to the center of a screw shaft is reduced, so that the heat is concentrated between the material barrel and the screw rod, and the novel heat concentrating and energy saving device has the advantages of heat concentration, energy saving, increased heat efficiency, increased torsion of the screw rod, quickness in the maintenance of the material barrel and the heat radiation of the screw rod and simple structure.

Description

Technical field: [0001] Involves injection molding machines and rubber extruders. Background technique: [0002] At present, the fillers of injection molding machines and rubber extruders are heated and melted, and the thermal efficiency is uneven. Too high heating temperature of the screw leads to reduced torque, weakened strength, and slow heat dissipation of the mechanical maintenance screw, which has a great impact on the working efficiency of the extruder. Invention content: [0003] In order to overcome the above deficiencies, the present invention provides a novel heat-gathering and energy-saving device for plastic extruders. The technical scheme that the present invention solves its technical problem to take is: [0004] Inside the barrel, the screw of the plastic extruder is hollowed out into a hollow shaft. [0005] A heat insulating cylinder is installed in the hollow shaft to connect with the hollow shaft structure, which prevents the heat transfer of the scr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B29C47/78B29C47/60

CPCB29C48/832

Inventor 钱慧萍

Owner 钱慧萍

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com