Three-dimensional non-woven fabric bag stamping and welding machine

A bag welding machine, non-woven bag technology, applied in envelope/bag manufacturing machinery, paper/cardboard containers, containers, etc., can solve the problem that non-woven three-dimensional bags cannot be placed upright and the production cost of non-woven three-dimensional bags High, non-woven three-dimensional bags with unclear edges and corners, to achieve the effect of outstanding substantive features, good bottom strength, and strong three-dimensional sense

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

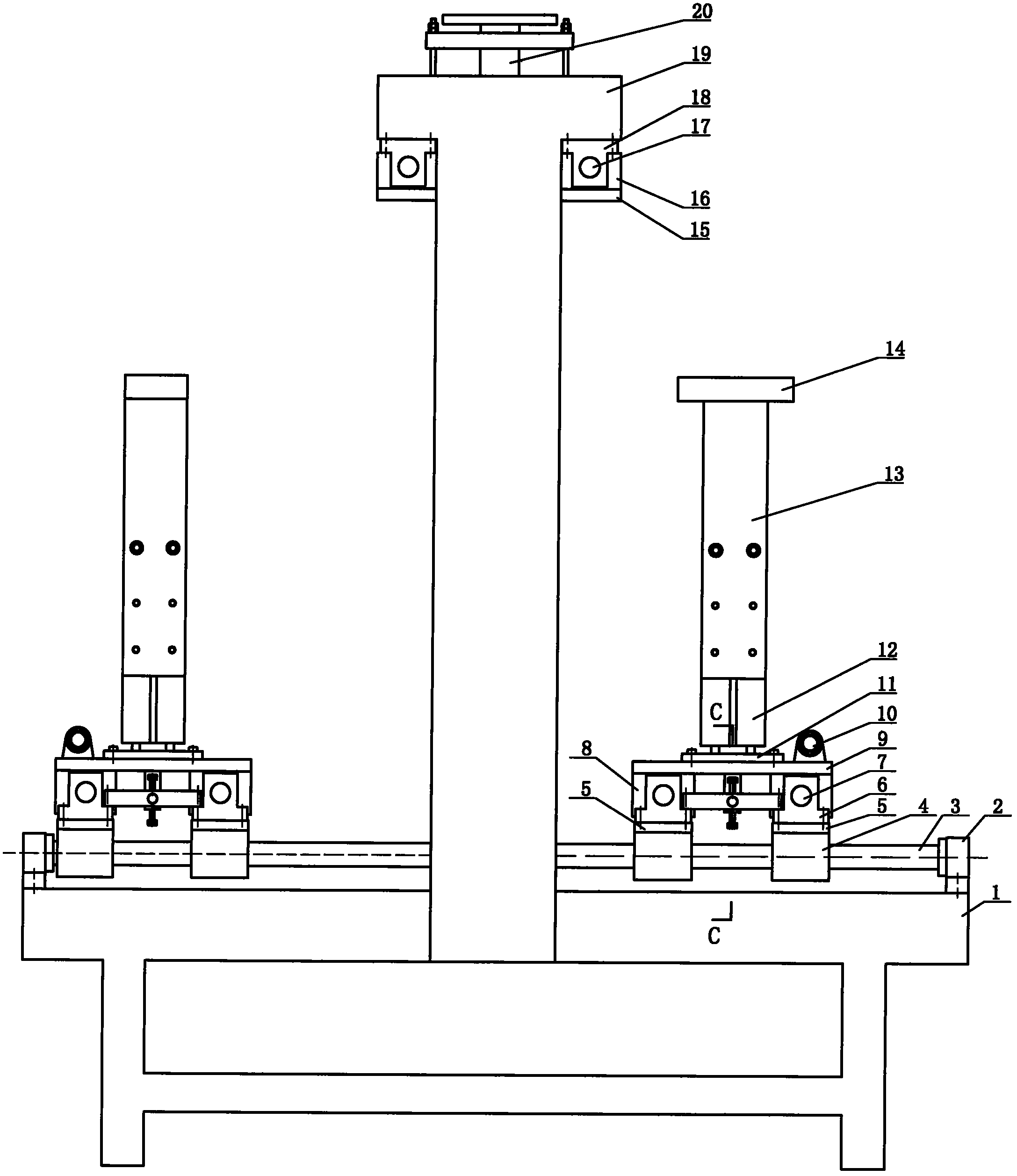

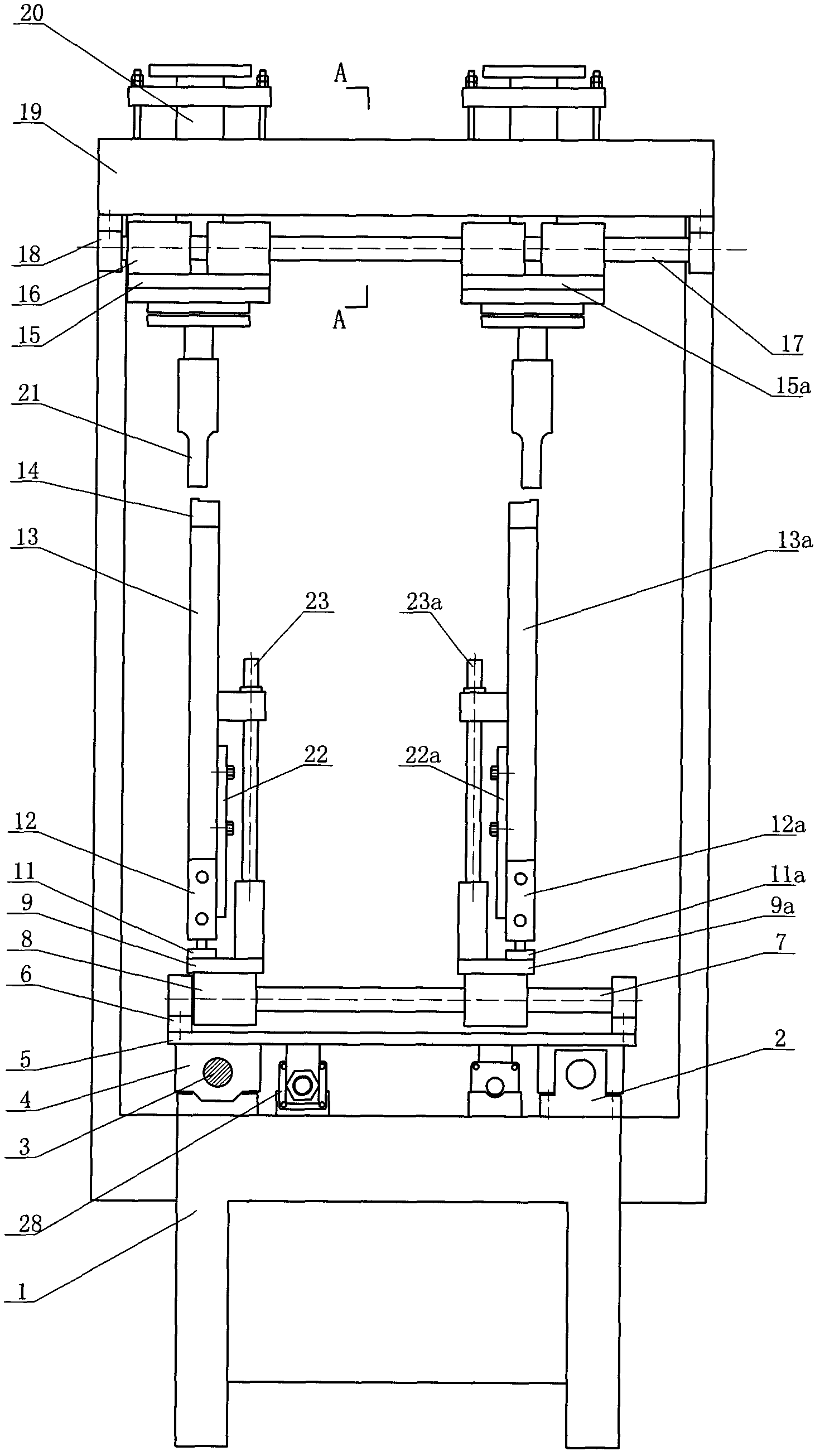

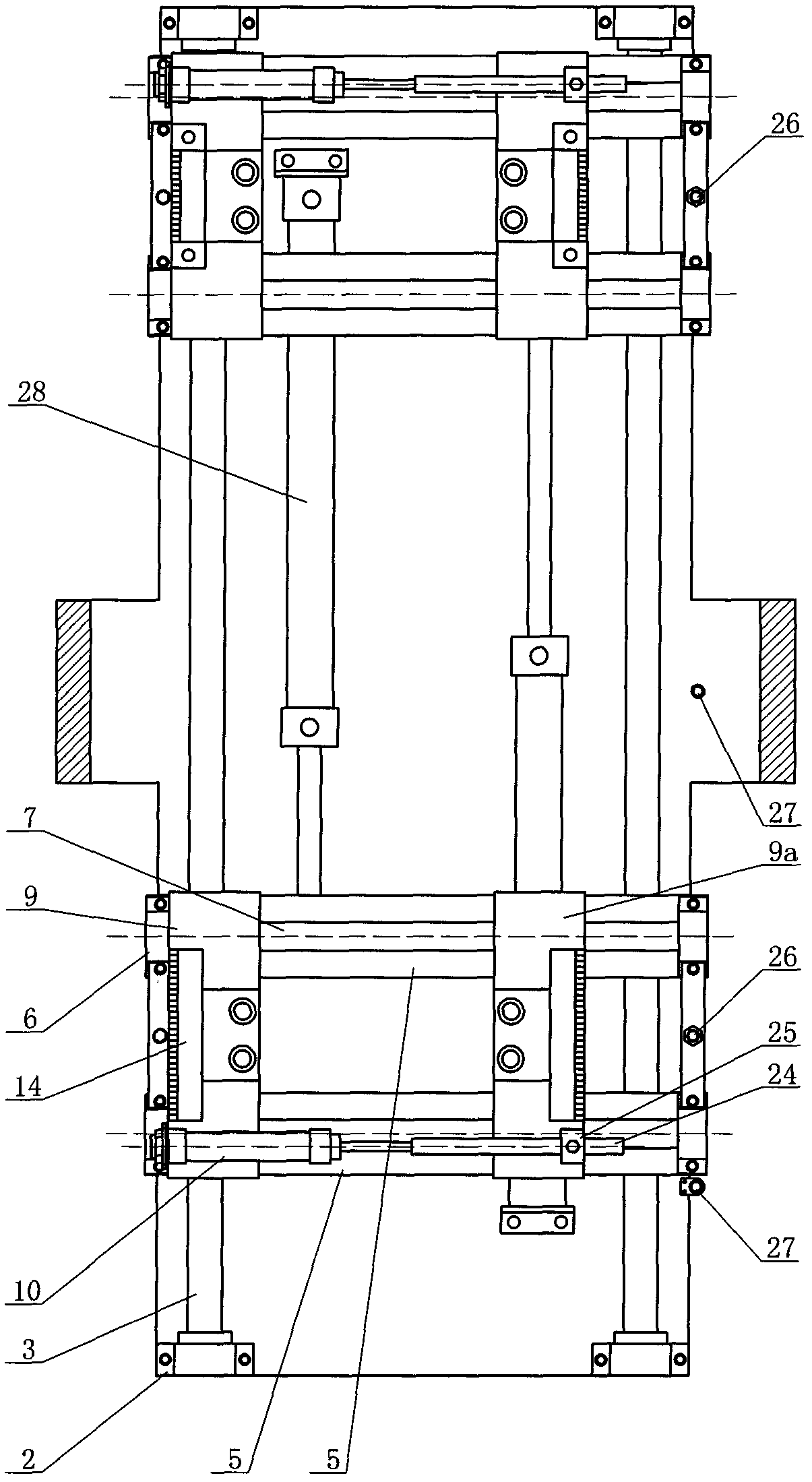

[0020] Refer to attached figure 1 , 2 3. The non-woven three-dimensional bag heat welding machine of the present invention includes a workbench 1 and a heat welding work group, and the heat welding work group is provided with two groups, which are respectively arranged at the front and rear ends of the workbench 1 The hot welding working group includes a bag support mechanism, a slide table 5 and a hot welding mold, and the bag support mechanism includes a left support arm 13, a right support arm 13a, a horizontal cylinder 10, a left slide seat 9, a right slide seat 9a, a middle slide Block 8 and transverse guide post 7, left support arm 13 is supported and guided by the guide post 23 fixedly installed on the left sliding seat 9, and the bottom of left support arm 13 is provided with left hot welding cylinder 12 (for double-rod cylinder), The left ironing cylinder 12 is connected with the left support arm 13 by a connecting plate 22, and the piston rod of the left ironing cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com