Same-diameter impeller group working by using fluid power

A technology of fluid power and impeller group, which is applied in the direction of reaction engine, hydroelectric power generation, engine components, etc. It can solve the problems that cannot be effectively solved, the exhaust speed cannot be greatly increased, and the performance of the impeller group cannot be satisfied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

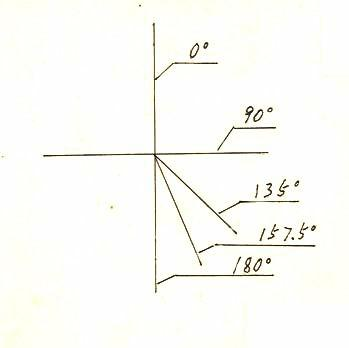

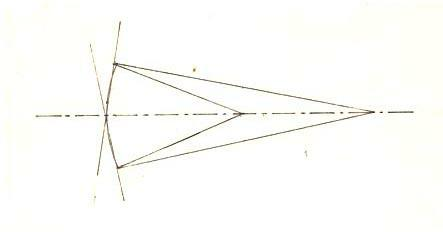

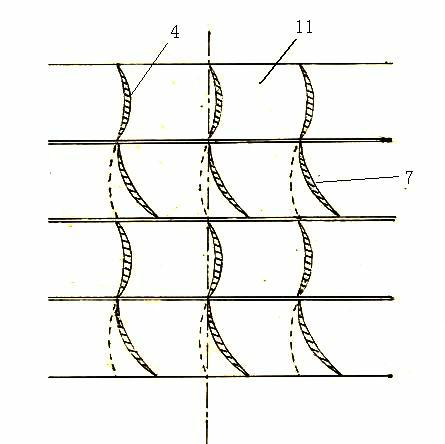

[0045] Accompanying drawing is a kind of specific embodiment of the present invention. The same-diameter impeller group using fluid dynamics is characterized in that: the flow path of the same-diameter impeller group is a slow wave-shaped flow path 11, and the slow wave-shaped flow path 11 is composed of a multi-proportional linear blade 7 and a guide blade 4 that are tangentially matched at one end Corresponding to the configuration, the turning angles of the fluid convection flowing through the guide vanes 4 and the multi-proportional line vanes 7 are all 45 degree arcs. The multi-proportional line blade 7 includes a leaf center C, a leaf root B, and a leaf top D, and the leaf center C, leaf root B, and leaf top D are respectively provided with a leaf center proportional line, a leaf root proportional line, and a leaf top proportional line, and the leaf The middle ratio line is designed according to the optimal ratio of 2 to 1, the blade root ratio line is designed according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com