Black-colored photosensitive resin composition, black matrix prepared by using thereof and color filter comprising the black matrix

A technology of photosensitive resin and composition, which is applied in different fields to improve the formation of fine patterns, and can solve the problems of over-erosion of the developer, hindering the photocrosslinking of photosensitive black pigments, and lowering the sensitivity, so as to improve the optical density difference, Excellent storage stability, the effect of reducing thermal fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

[0093] Preparation of Pigment Dispersion Liquid M

[0094] 20.0g of carbon black, 6g of AJISPER PB821 (produced by Ajinomoto Fine Chemicals Co., Ltd.) as a dispersant, and 74g of propylene glycol monomethyl ether acetate as a solvent were mixed and dispersed in a bead mill for 12 hours to prepare Pigment dispersion M.

Synthetic example 1~20

[0095] Synthesis of Alkali-Soluble Resin

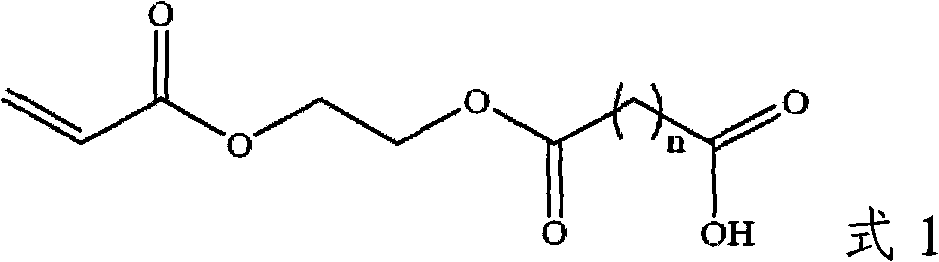

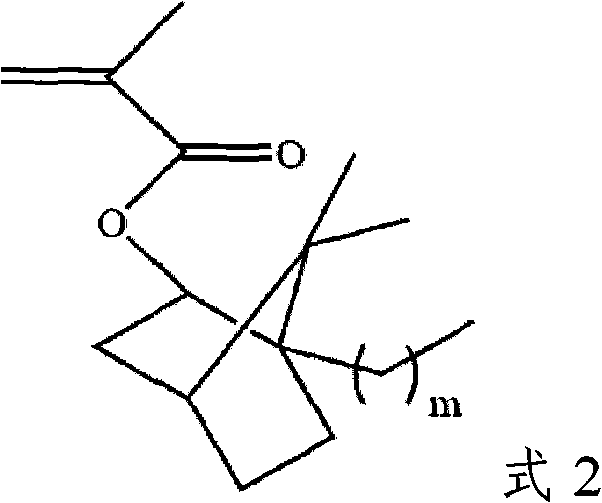

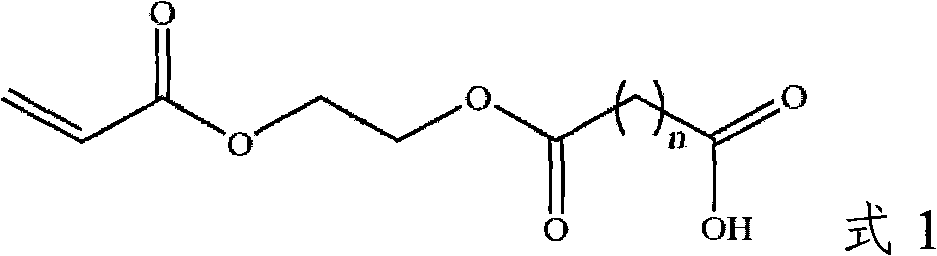

[0096] In a 1000mL flask equipped with a stirrer, a thermometer, a reflux condenser, a dropping funnel, and a nitrogen conduit, add propylene glycol monomethyl ether in the following Table 2 and Table 3 (the unit of the following Tables 2 and 3 is g). Acetate (PGMA), AIBN, 2-Acryloyloxyethylsuccinate (B-1), N-Phenylmaleimide, Styrene, Methacrylic Acid, Isobornyl Methacrylate Type (B-2), nitrogen gas (replacing air with nitrogen gas, the unit in Table 2 and Table 3 below is g). Then, the temperature of the reaction liquid was raised to 100° C. while stirring, and then reacted for 7 hours. The final solid content of the alkali-soluble resin thus synthesized, the acid value of the solid content, and the weight-average molecular weight measured by GPC are shown in Tables 2 and 3. (B-1) and (B-2) used in each synthesis example are the same as in Table 1 below.

[0097] Table 1

[0098]

[0099]

[0100] Table 2

[0101]

...

Embodiment 1~17

[0104] Preparation of black photosensitive resin composition

[0105] A black photosensitive resin composition was prepared with the compositions in Tables 4 and 5 below by a method known in the art. The unit of the following Tables 4 and 5 is g.

[0106] Table 4

[0107]

[0108] table 5

[0109]

[0110] 1) KAYARAD DPHA (manufactured by Nippon Kayaku Co., Ltd.)

[0111] 2) Ciba Specialty Chemicals

[0112] 3) Ciba Specialty Chemicals

[0113] 4) Ciba Specialty Chemicals

[0114] 5) 4,4'-bis(N,N'-dimethylamino)-benzophenone (manufactured by Hodogaya Chemical Industry Co., Ltd.)

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com