Sensor head with self sterilization and cleaning functions

A sensor head and sensor body technology, applied in the field of sensor heads, can solve the problems of difficult unification of sensors, high maintenance cost, and difficult to display, and achieve the effect of ensuring cleaning effect, reducing maintenance cycle, and ensuring accuracy and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

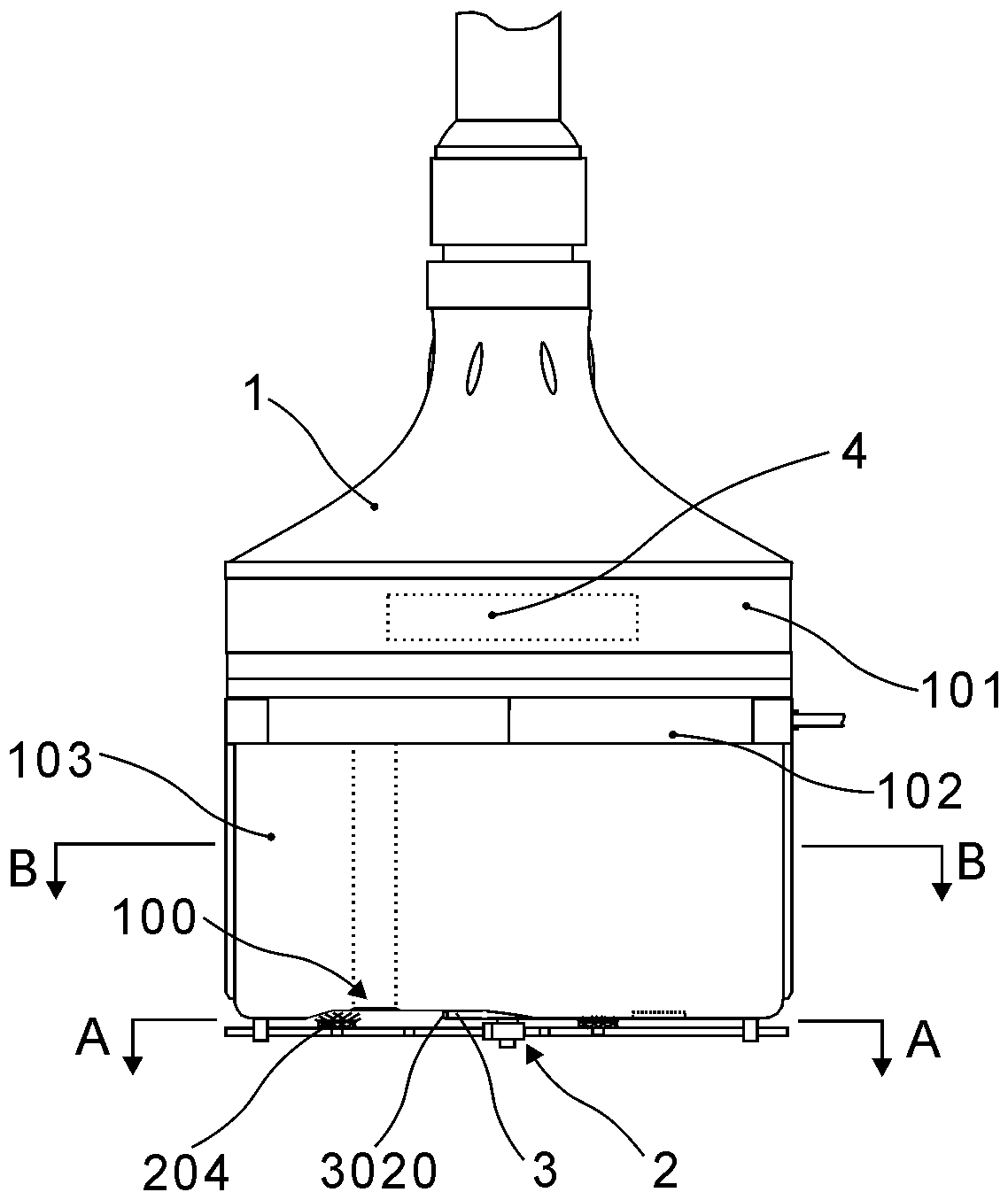

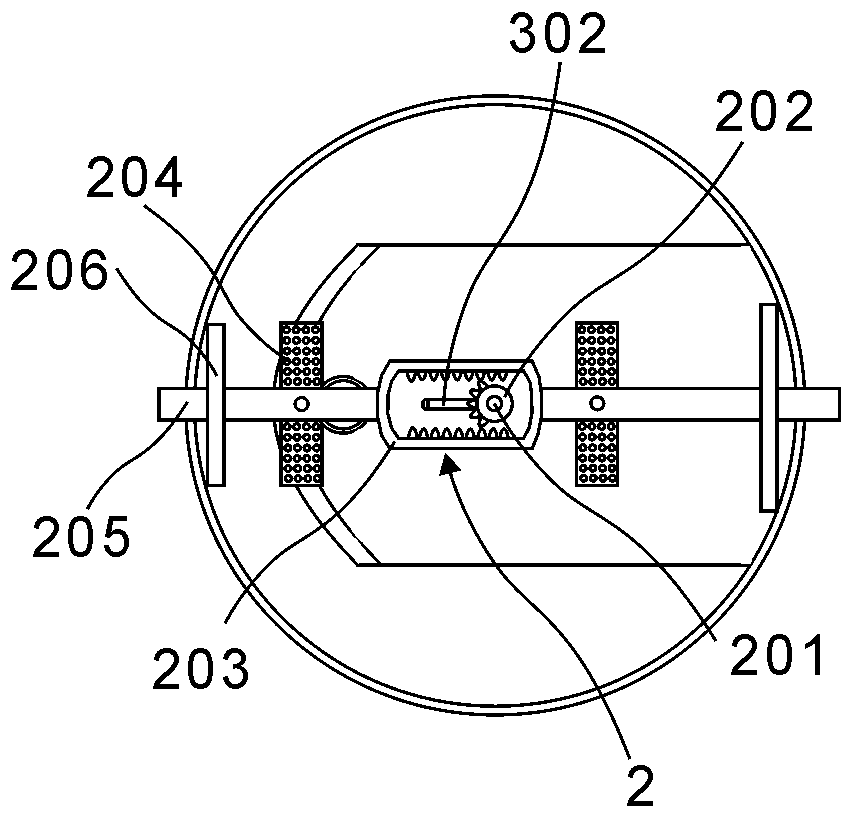

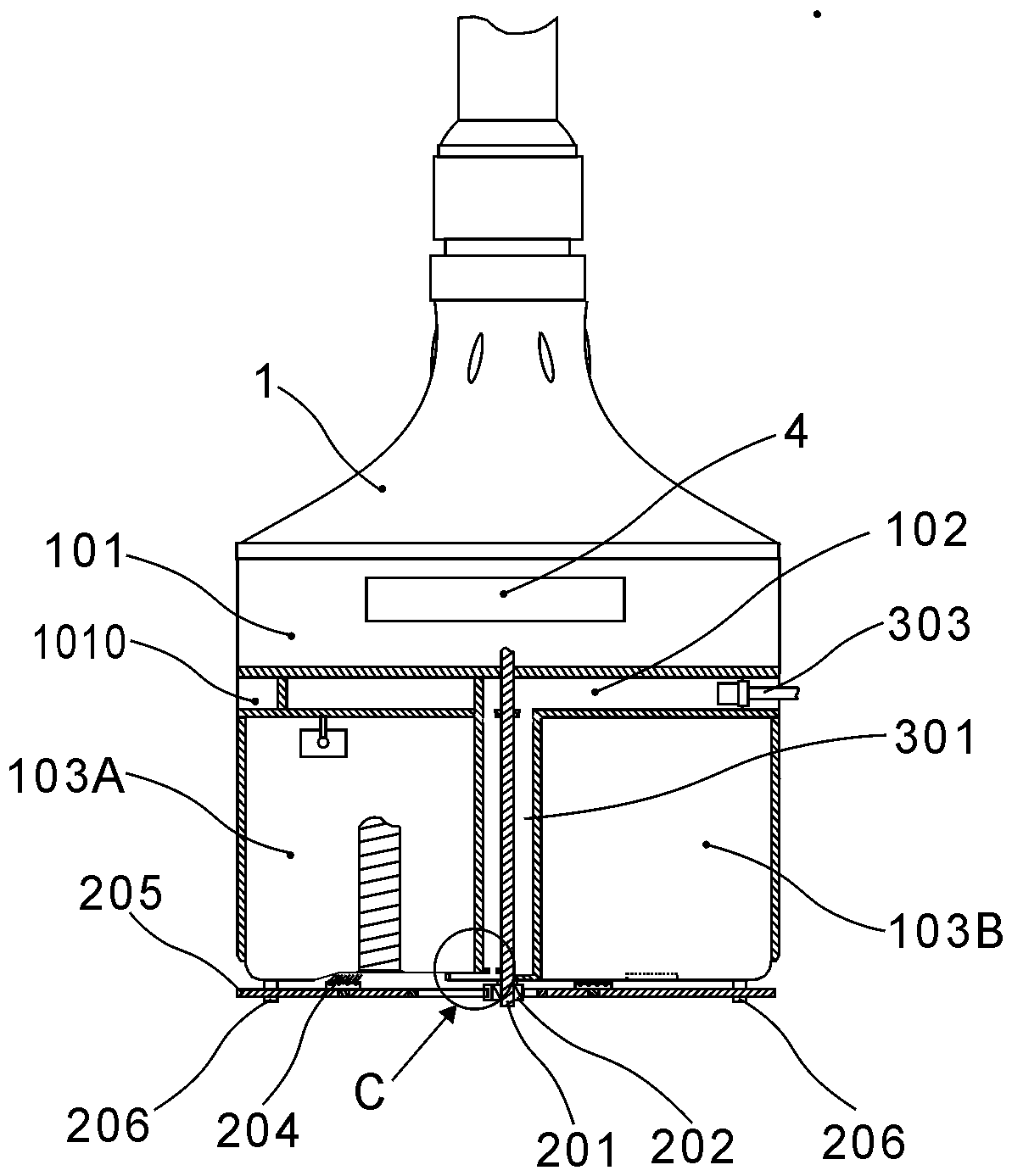

[0064] Such as Figure 7 As shown, it is a galvanic electrochemical dissolved oxygen sensor capable of self-sterilization and cleaning. The chamber 103 of the measuring device is equipped with a chemical electrolyte mainly composed of KCL, and is fixed with a pure iron block 501 and a pure silver rod 503. And a gap is provided on the pure silver rod 503, and a temperature sensor 502 is sealed, and the measurement sensitive area 100 is a thin film suite 504,

[0065] The driver 4 includes an intelligent control processing board, the intelligent control processing board is electrically connected to the devices or components in the measuring device chamber 103, and the thin film package 504 is used to perceive the original signal of dissolved oxygen in the water body, through the Intelligent control processing board analysis processing. In this embodiment, the driver 4 also includes a microprocessor, and a motor and a deceleration device 401 connected to the microprocessor. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com