Mrthod of manufacturing bush assembly and vibration insulating rubber bush

A technology of rubber bushing and manufacturing method, which is applied in the direction of springs, springs, springs/shock absorbers made of plastic materials, etc., can solve the problem that the anti-detachment force of the vibration-isolating rubber bushing cannot be fully improved, and achieves the improvement of the anti-detachment force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

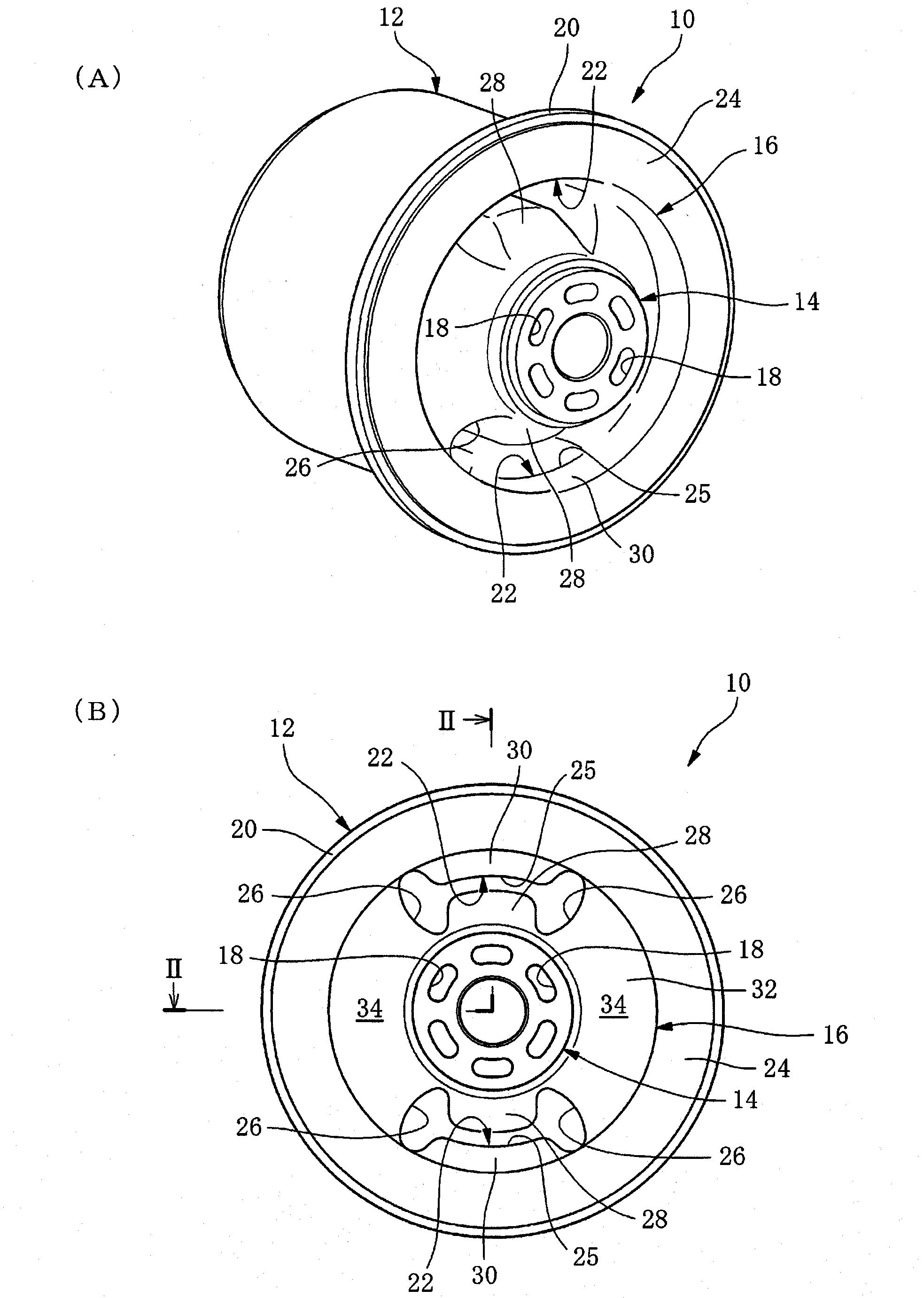

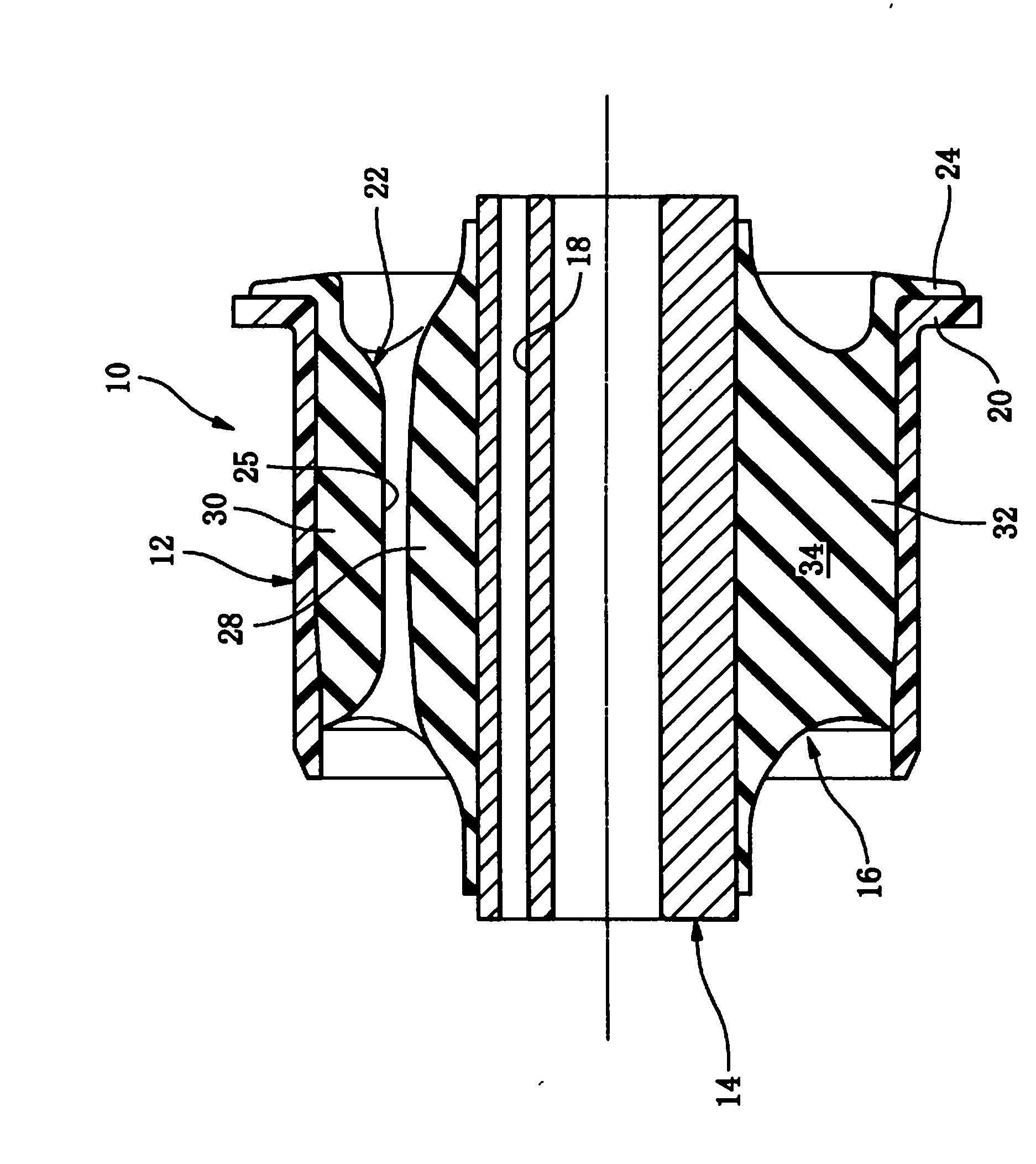

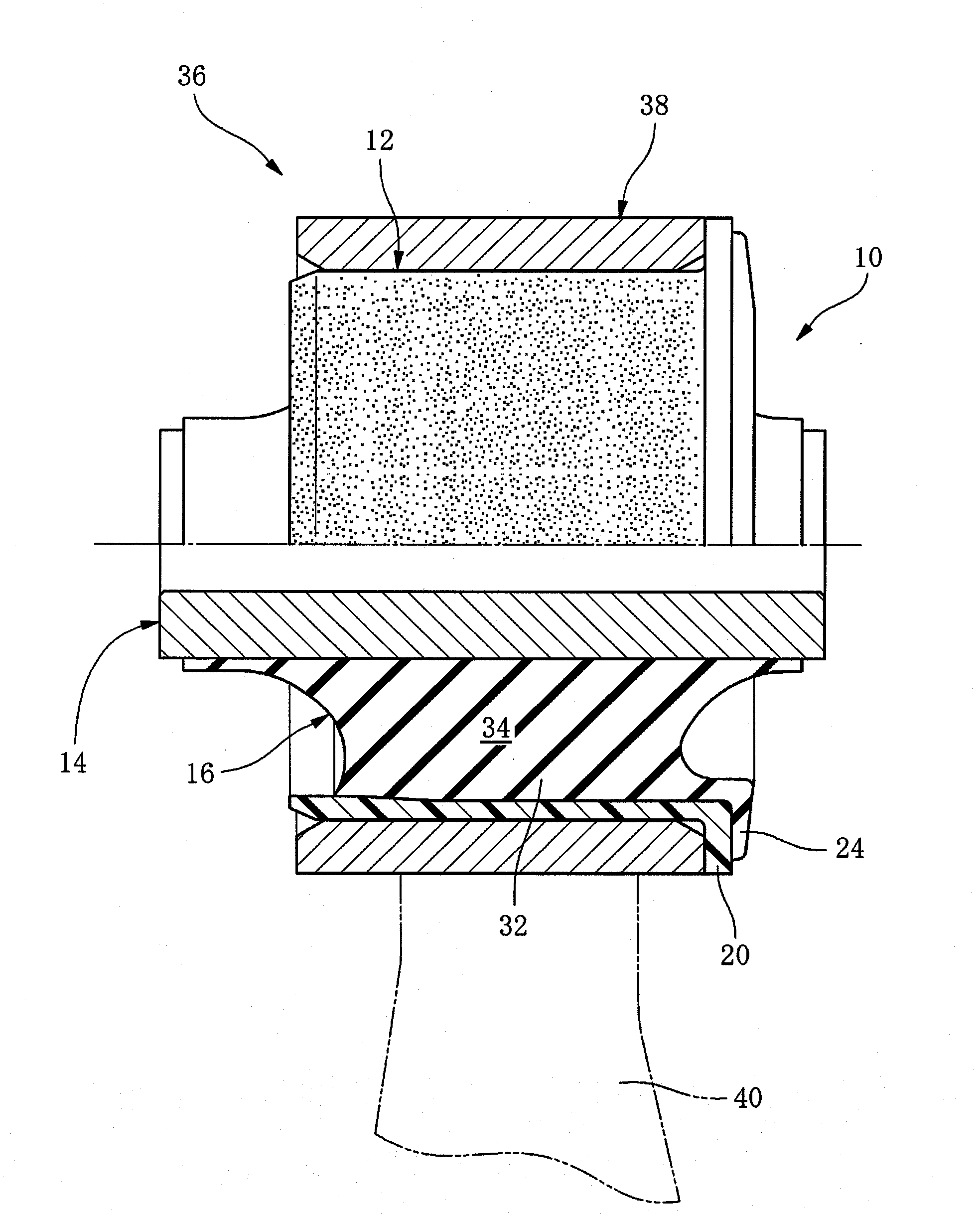

[0075]Next, an embodiment in which the present invention is applied to a vibration-isolating rubber bush as a rear trailing arm bush of a vehicle and to an assembly of the vibration-isolating rubber bush will be described in detail with reference to the drawings.

[0076] exist figure 1 with figure 2 Among them, reference numeral 10 denotes the vibration-isolating rubber bushing of this embodiment, and the vibration-isolating rubber bushing 10 includes a cylindrical outer cylinder 12, a cylindrical inner cylinder 14, and an elastically connected outer cylinder 12. The state of the outer cylinder 12 and the inner cylinder 14 is vulcanized and bonded into a rubber elastic body 16 in the state of the inner cylinder 14 .

[0077] The inner cylinder 14 is made of metal, here an extruded member of aluminum alloy, and is formed in the circumferential direction with a plurality of cavities 18 penetrating in the axial direction.

[0078] On the other hand, the outer cylinder 12 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com