Cassava crushing method

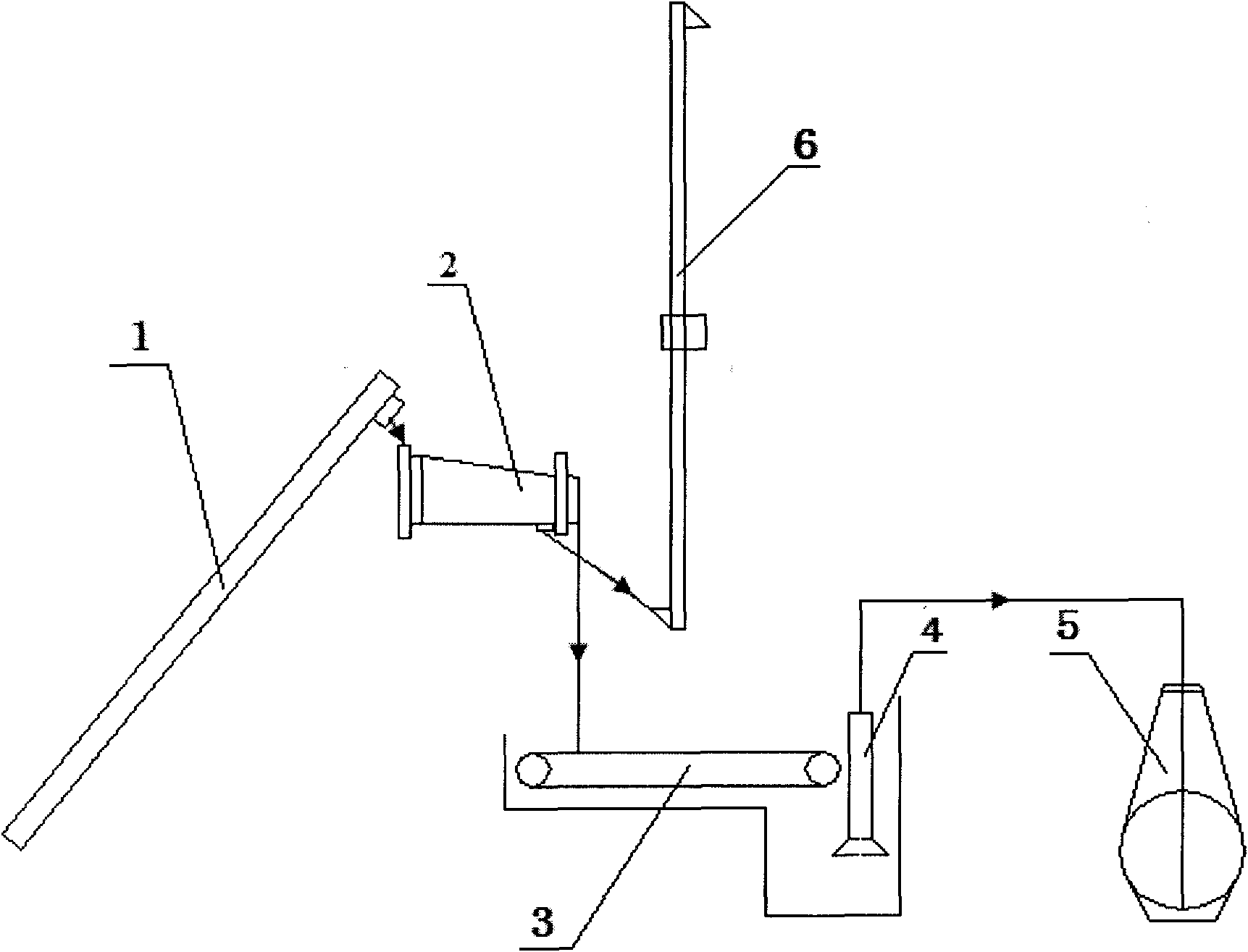

A cassava and crushing system technology, applied in grain processing and other directions, can solve the problems of low conveying efficiency, easy failure of conveying devices, unfavorable conveying and crushing of cassava raw materials, etc., and achieve the effect of improving conveying efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

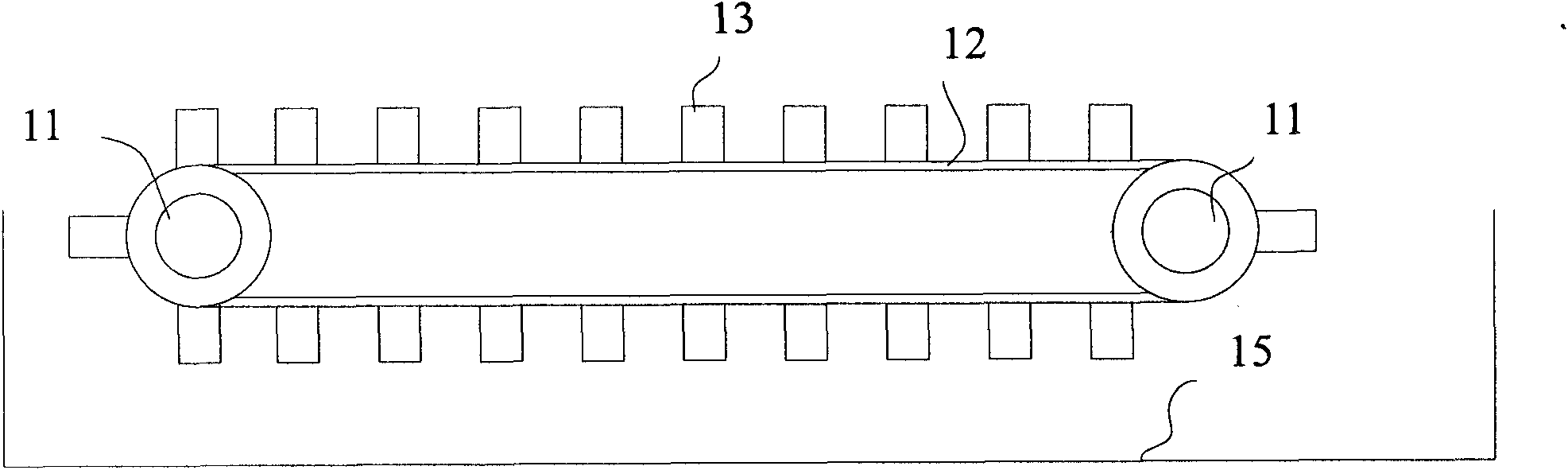

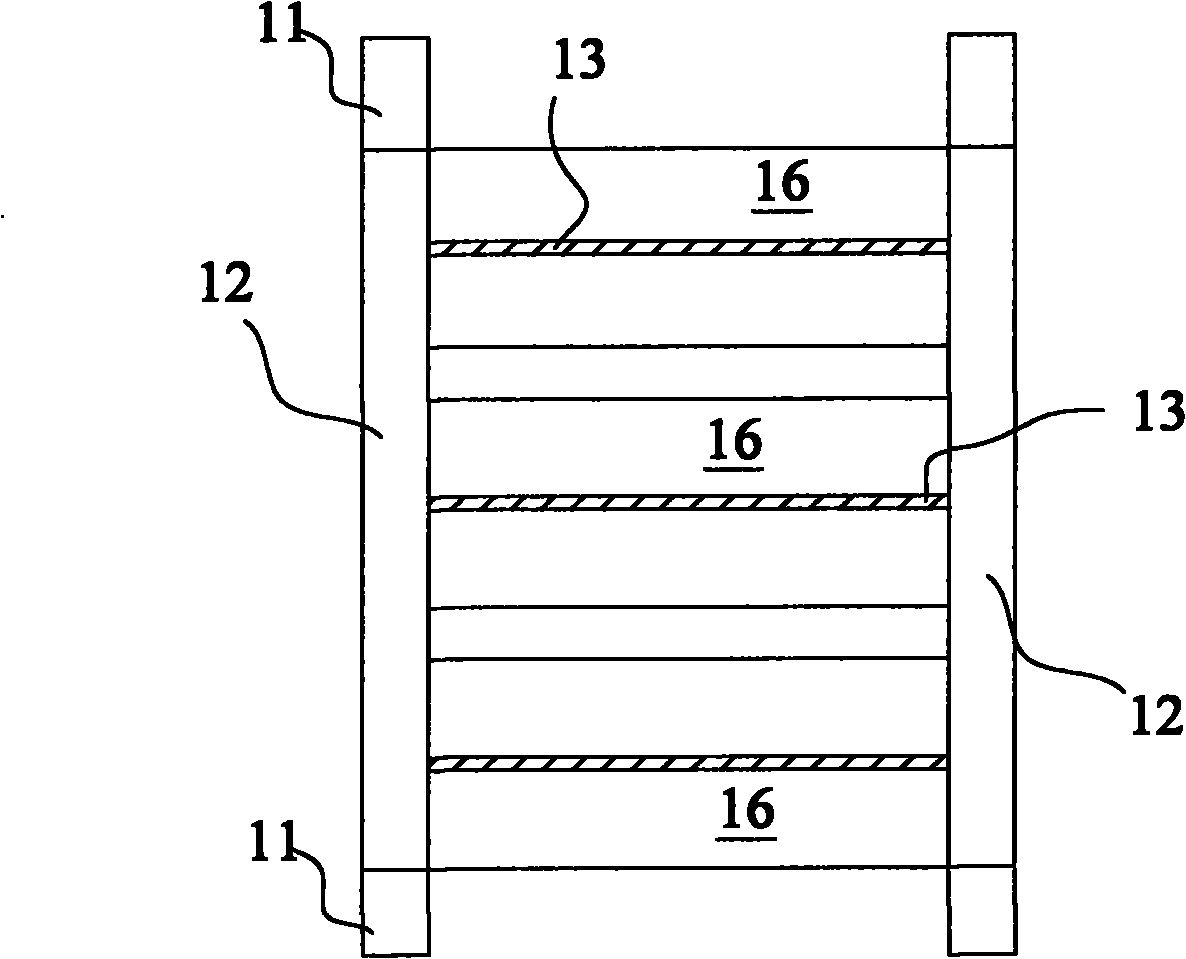

[0031] According to the first specific embodiment of the present invention, such as figure 2 As shown, an open space capable of accommodating materials should be formed between two adjacent box plates 13 and the transmission chain 12 to meet the needs of accommodating and transporting materials; generally speaking, the box between the axis of the drive roller 11 The angle (β) between the plane where the plate 13 is located and the plane where the transmission chain 12 is located can be 30°-90°, preferably 60°-90°; according to the second specific embodiment of the present invention, as Figure 5 As shown, an open space capable of accommodating materials should be formed between two adjacent box plates 13 and base members 16 to meet the needs of accommodating and transporting materials; generally speaking, the box between the axis of the drive roller 11 The included angle (β) between the plane of the board 13 and the plane of the base member 16 may be 30°-90°, preferably 60°-9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com