Rubber spring damping shock absorber

A rubber spring and shock absorber technology, applied in the field of damping shock absorbers, can solve problems such as unsatisfactory, and achieve the effects of reducing seismic energy, convenient and quick installation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

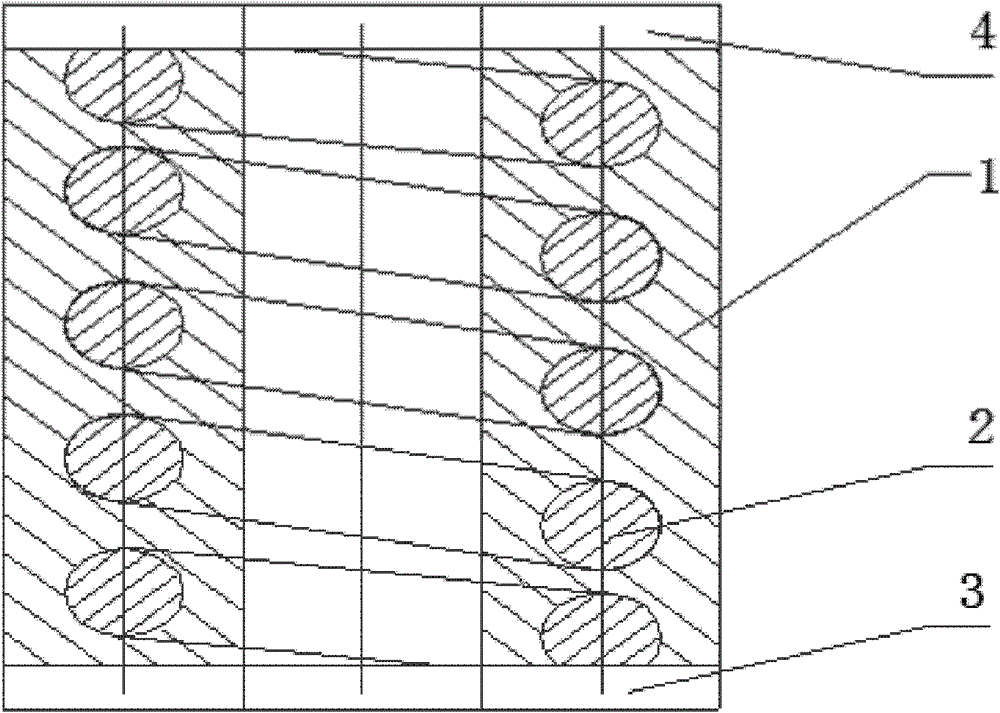

[0028] The rubber spring damping shock absorber of the present embodiment, as figure 1 As shown, it consists of high damping rubber 1, cylindrical helical compression spring 2, lower base 3 and upper base 4, high damping rubber 1 and cylindrical helical compression spring 2 are solidified together by vulcanization, lower base 3 and upper base 4 are connected with high The damping rubbers 1 are bonded together by glue.

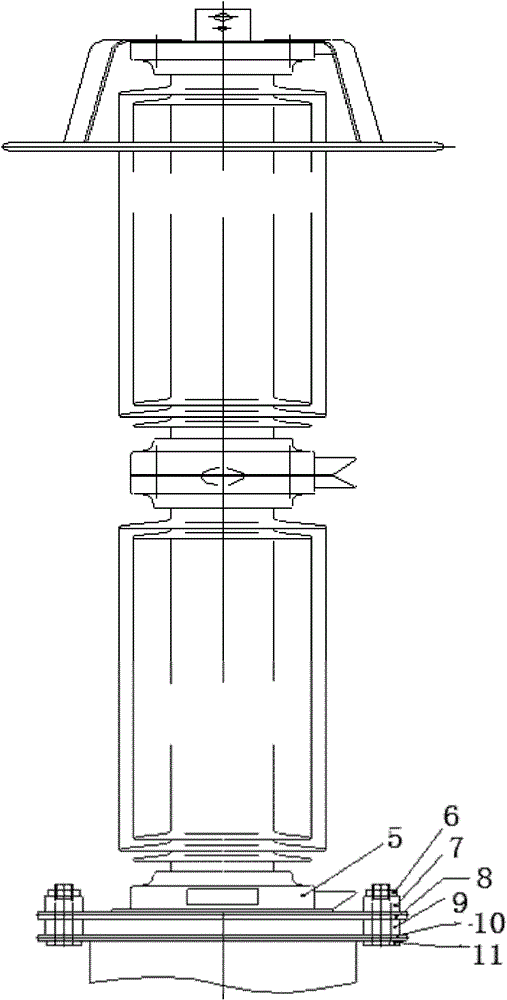

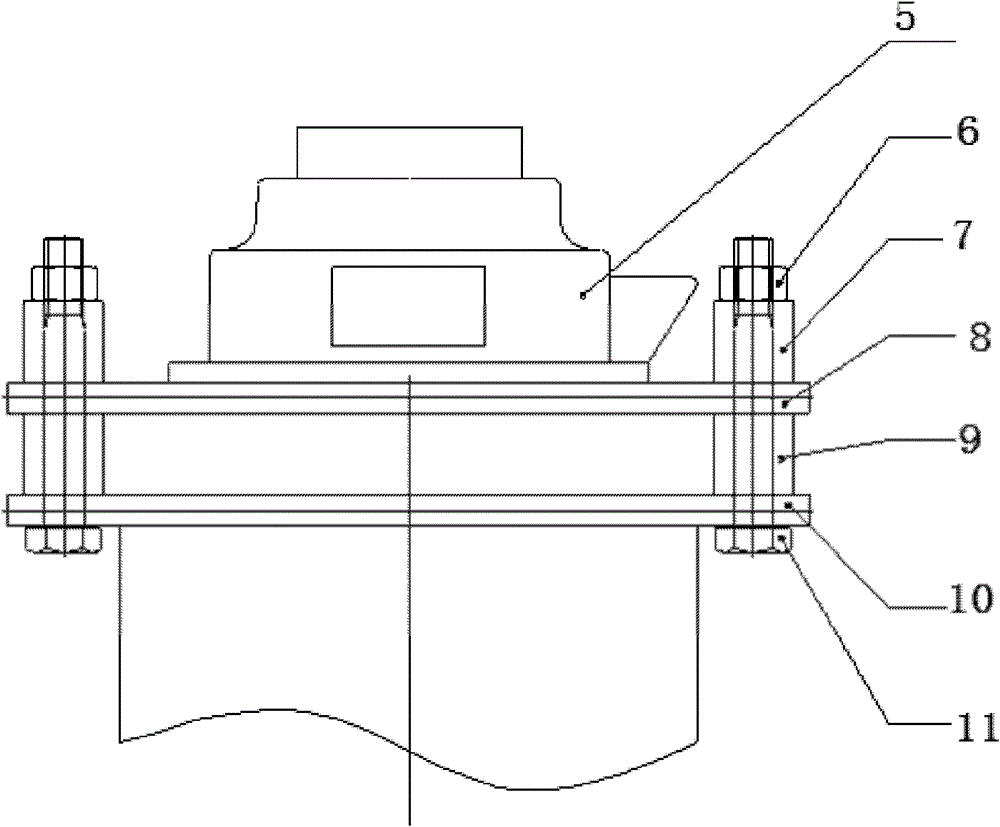

[0029] Take the lightning arrester as an example, such as figure 2 and image 3 As shown, the core component in the use state diagram is the rubber spring damping shock absorber 7 or 9. When an earthquake comes, the rubber spring damping shock absorber 7 or 9 will use its own buffering and damping effect to effectively reduce the lightning arrester of the upper structure. 1 earthquake response, thus playing a protective role. The superstructure lightning arrester 1 is connected and fixed with the connecting plate 8 by bolts; above and below the connecting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com