On-line back flushing device of panel-type heat exchanger and flushing method thereof

A technology for backwashing and heat exchangers, applied in the direction of cleaning heat transfer devices, flushing, lighting and heating equipment, etc., can solve the problems of blockage of cooling water in heat exchangers, melting of bearing bushes of operating equipment, deterioration of heat exchange effects, etc. The effect of small drainage resistance, small investment and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

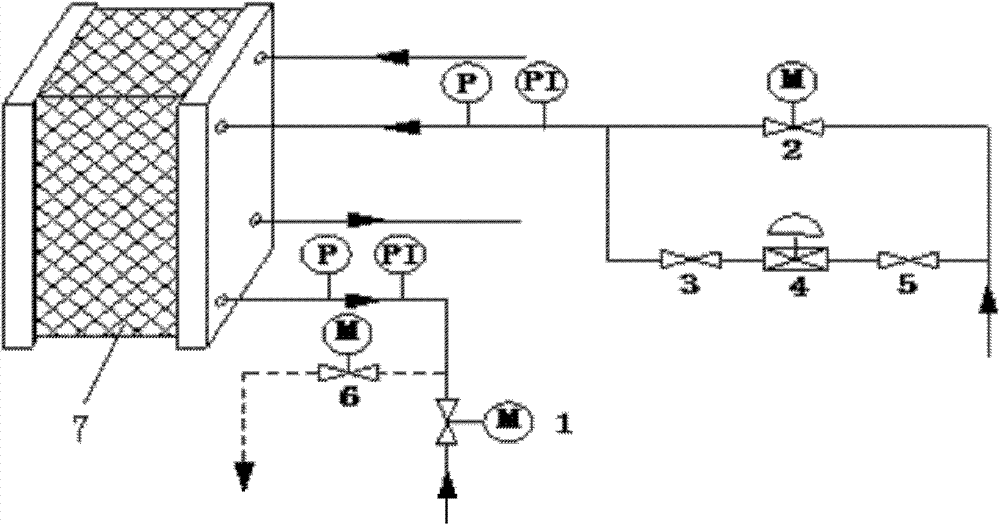

[0018] figure 1 Among them, an online backwashing device for a panel heat exchanger, which includes a panel heat exchanger 7, the panel heat exchanger 7 is connected to the cooling water inlet pipeline and the cooling water return pipeline, and the cooling water inlet pipeline is also A backwash drainage pipeline is provided, and a backwash operation valve 6 is arranged on the backwash drainage pipeline; at least one pressure gauge and at least one pressure transmitter are respectively arranged on the cooling water return pipeline and the cooling water inlet pipeline . A cooling water inlet operation valve 1 is provided on the cooling water inlet pipeline.

[0019] The cooling water return pipeline is divided into two parallel pipelines, one of which is provided with a cooling water return bypass operation valve 2, and the other pipeline is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com