Spare part profile processing method

A processing method and component technology, applied in the direction of electrical program control, digital control, etc., can solve the problems of high error rate, low processing efficiency, cumbersome calculation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

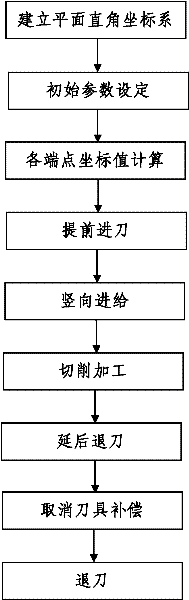

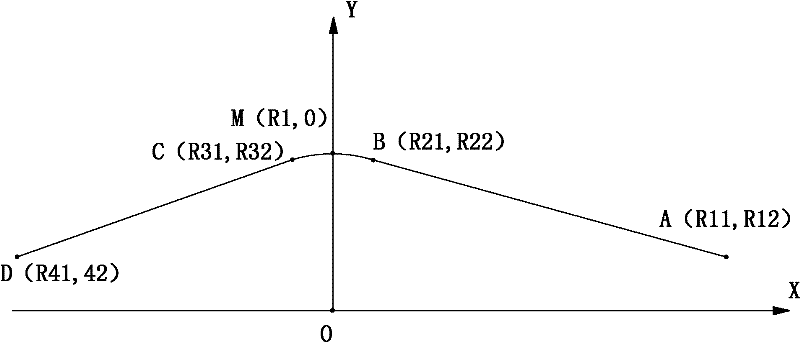

[0061] Such as figure 1 A method for processing the contour of a part, the contour line of the processed contour is composed of a circular arc segment and two straight line segments arranged on the same plane, and the two straight line segments are respectively connected with the left and right sides of the circular arc segment The end points are connected and both are tangent to the arc segment, and the two straight line segments are respectively a straight line segment CD connected to the left end point C of the arc segment and a straight line segment connected to the right end point B of the arc segment. The connected straight line segment AB, the central angle α<180° corresponding to the arc segment, the tangent point between the straight line segment AB and the arc segment is the right end point B of the arc segment, the straight line segment CD and the arc segment The tangent point is the left end point C of the arc segment, and the processing method includes the follow...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap