Substrate processing device

A substrate processing device and a technology for processing space, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problem of increasing manufacturing costs, maintenance costs and repair costs, limiting the implementation of temperature control methods, and increasing the overall manufacturing of chambers cost and other issues, to achieve the effect of saving manufacturing cost and maintenance/repair cost, saving manufacturing cost, and minimizing thermal deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is described in detail with reference to the accompanying drawings.

[0036] Next, the substrate processing apparatus according to the present invention will be further described in detail with reference to the accompanying drawings.

[0037] A substrate processing apparatus according to the present invention is used to perform a predetermined process on a substrate. The substrate processing device may include all of a load lock device, a vacuum processing device, a transfer module, etc., or may include at least one of them.

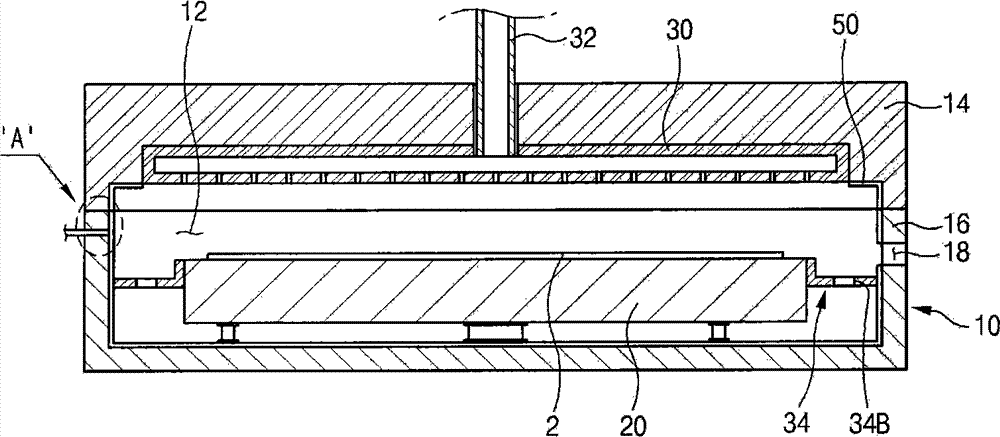

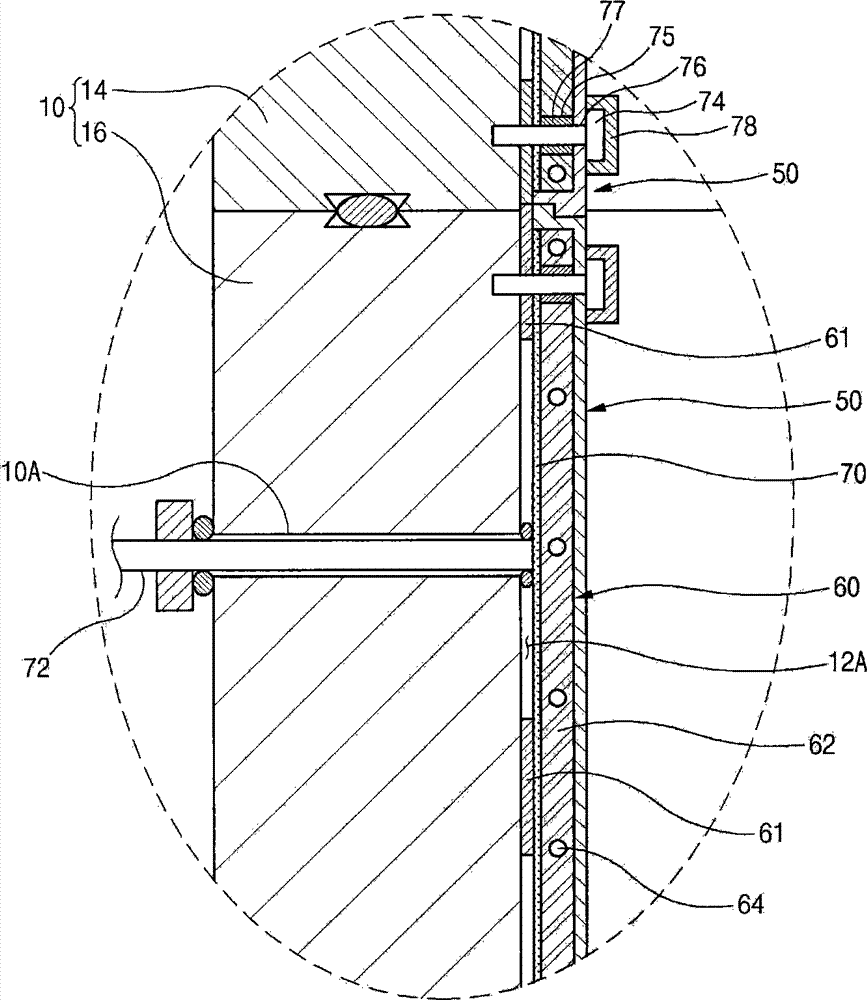

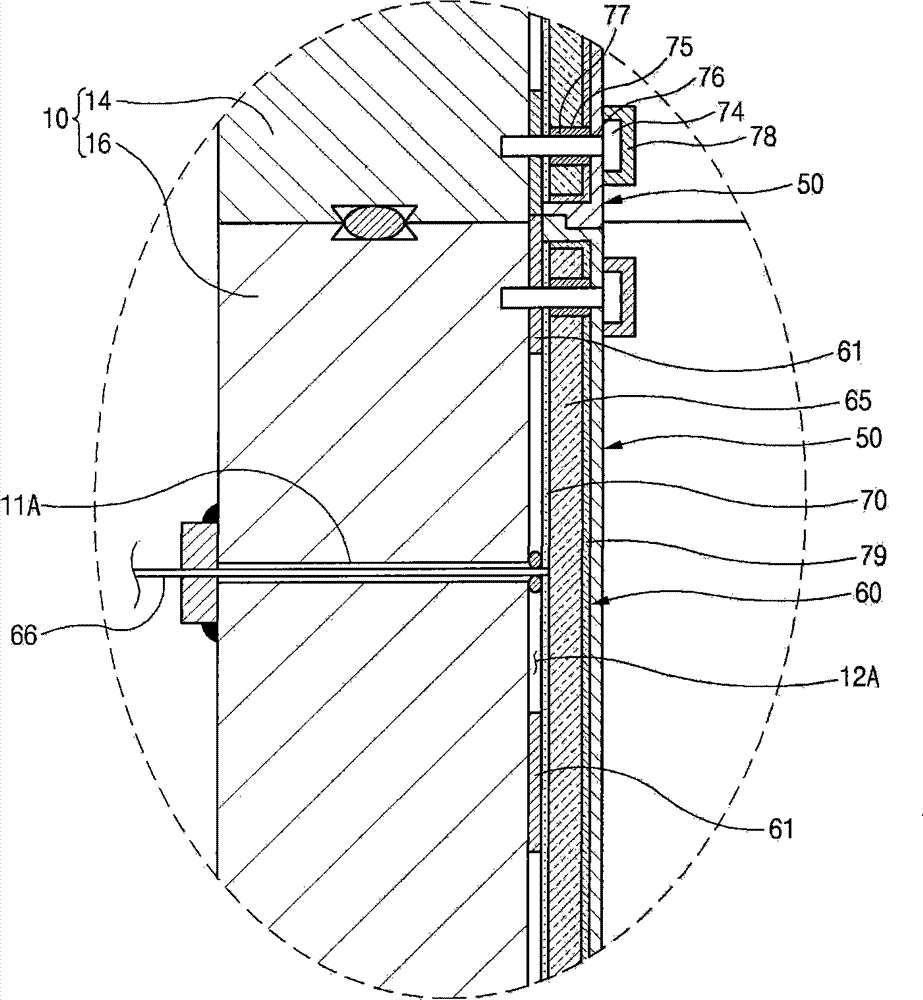

[0038] figure 1 is a cross-sectional view of a substrate processing apparatus according to a first embodiment of the present invention, figure 2 yes figure 1 A magnified view of part 'A' in , and image 3 and figure 2 Correspondingly, a substrate processing apparatus according to a second embodiment of the present invention is shown.

[0039] As shown, the substrate processing apparatus according to the first embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com