Sieve basket for coal slime solid-liquid separator

A technology of solid-liquid separator and coal slime, which is applied in filtration separation, separation method, moving filter element filter, etc., can solve the problems of long time period, dismantling and unloading, affecting production, etc., so as to reduce moisture and save costs. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

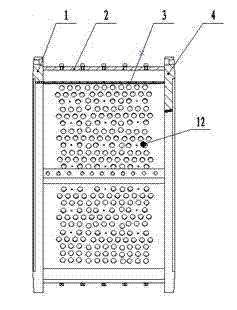

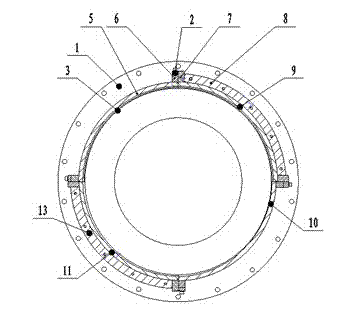

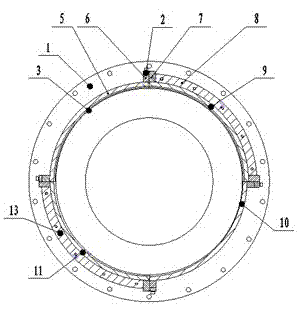

[0023] Example: figure 1 , figure 2 As shown, this embodiment includes a left flange 1, a pillar 2, a screen 3, a right flange 4, a screen bracket, a connecting plate 6, a pillar 7, and a connecting plate 8, and four pillars 2 are equidistantly arranged on the left side. Between flange 1 and right flange 4. The screen bracket is arranged between the left flange 1 and the right flange 2, and the screen bracket is covered with permeable holes 12. The sieve is a stainless steel sieve.

[0024] The screen bracket consists of four arc-shaped split brackets 5, 9, 10, 11 to form a cylindrical cylinder, of which two split brackets 5, 10 are welded to the left flange 1 and right flange 2, and the other two The block split brackets 9, 11 are connected with the left flange 1 and the right flange 2 by bolts.

[0025] Specifically, the two split brackets 5 and 10 welded to the left flange 1 and the right flange 2 are axisymmetric positions.

[0026] A connecting plate 8 (left connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com