Temperature-control punching machine

A punching machine and punching technology, applied in the direction of metal processing, etc., can solve the problems of heating punches, profile fragmentation, processing and feeding troubles, etc., and achieve the effects of improving work efficiency, reducing fragmentation, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

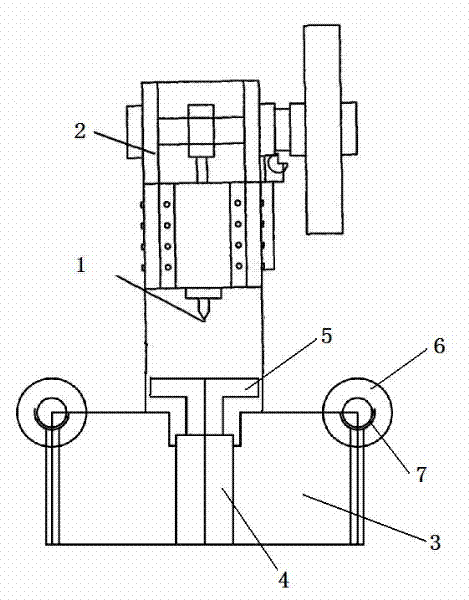

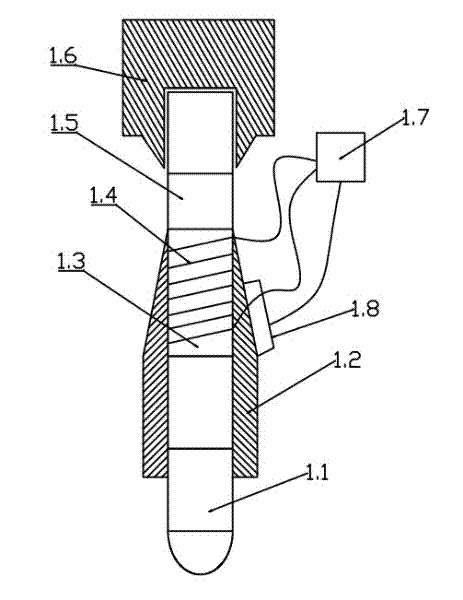

[0009] figure 1 , figure 2 The schematic diagram of a temperature-controlled punching machine shown includes a punching mechanism 1, a workbench 2, and a base 3. The punching machine is provided with a feeding mechanism 4 that drives the object to be punched to move, and is located on the base. The feeding mechanism 4 There are columns 7 at both ends, with grooves that can support the roller 6, on which the roller 6 can be passively rolled, driving the workpiece to move under the workbench 2, and the middle part is equipped with a hydraulic jacking device 5 to jack up the workpiece, The workpiece leaves the roller and is punched. The front end of the punching mechanism 1 is connected to the chain rod, the lower end of the chain rod is connected to the punch shaft 1.6, the lower port of the punch shaft 1.6 is equipped with a punch cover 1.5, the middle part of the head cover 1.5 is wound with a heat conducting rod 1.3 and the electric furnace wire 1.4, and the positive and ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com