Micro adaptive core for propelling pencil

A pencil and miniature technology, applied in mechanical pencils, printing, writing utensils, etc., can solve the problems of inability to determine whether the movement is qualified, affecting the appearance and performance of the entire pen, and poor standardization of the movement, achieving standardized production and shortening. Lead time, small overall size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment one (The front end of the tip sleeve is a plastic core-protecting tube head formed integrally with it).

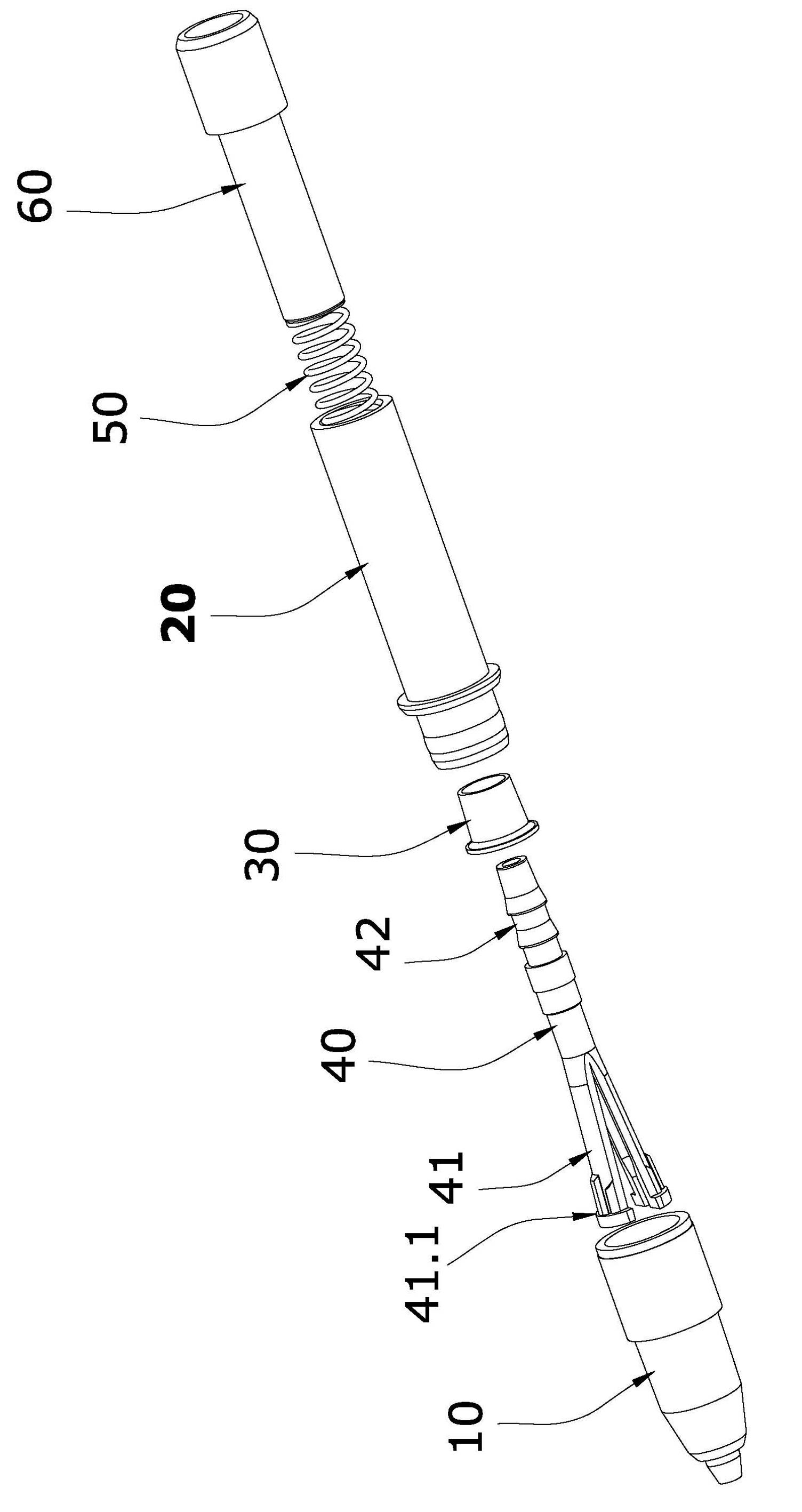

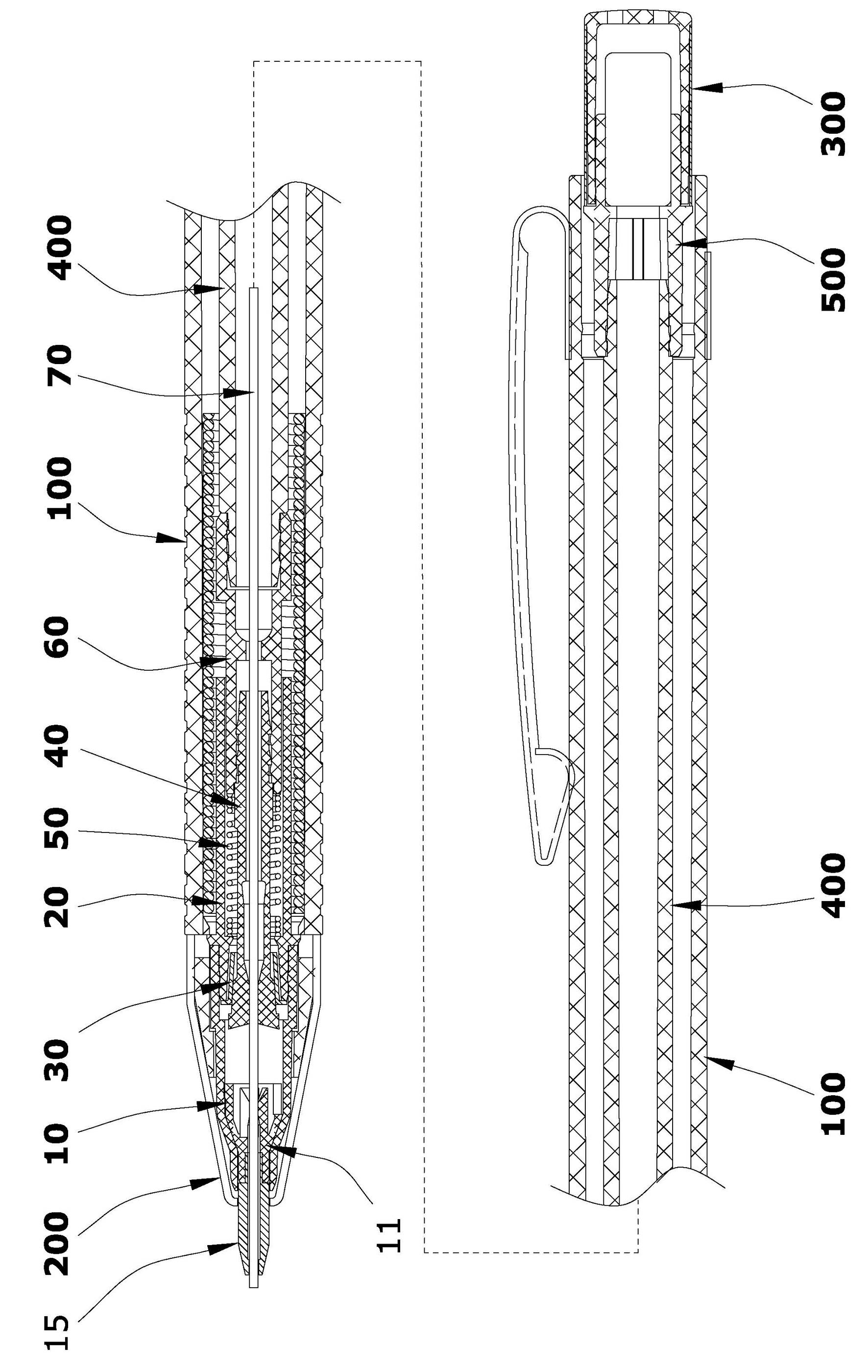

[0025] like figure 1 The shown micro-adapting movement for an active pencil is composed of a tip sleeve 10 , a spring seat 20 , a locking ring 30 , a collet 40 , a spring 50 and a core guide tube 60 .

[0026] like figure 1 and figure 2 As shown, a tip sleeve 10 that can be internally sleeved in the nib of an active pencil, the inner front of the tip sleeve 10 is integrally formed with two damping sheets 11.1 that are mutually matched with it, and the front end of the tip sleeve 10 is provided with a protective core integrally formed with it. Pipe head 12; a tubular spring seat 20, the front end of the spring seat 20 is covered with a movable locking hoop 30, and a tubular collet 40 is inserted into the spring seat 20; the front of the collet 40 is provided with at least two petals that can be used for clamping The elastic expansion clip 41 of...

Embodiment 2

[0030] Embodiment two (The tip sleeve is plugged with a metal core-protecting needle tube, and the damping member is a damping ring with a damping sheet).

[0031] like Image 6 and Figure 7 The micro-adaptive movement shown for a mechanical pencil is composed of a pointed sleeve 10, a spring seat 20, a locking hoop 30, a collet 40, a spring 50 and a core tube 60. This embodiment is the same as that of Embodiment 1. The difference is that the damping part is a damping ring 11 that is set inside the tip sleeve 10, and a three-claw damping piece 11.1 is fixed in the damping ring 11, and a protective core tube head 12 is inserted into a protective lead core. Protective needle tube 14 ; Other structures, assembly relations and working principles of the present invention are the same as in Embodiment 1.

Embodiment 3

[0032] Embodiment three (The tip sleeve is plugged with the copper head of the protective core, and the damping part is a damping ring with a damping sheet).

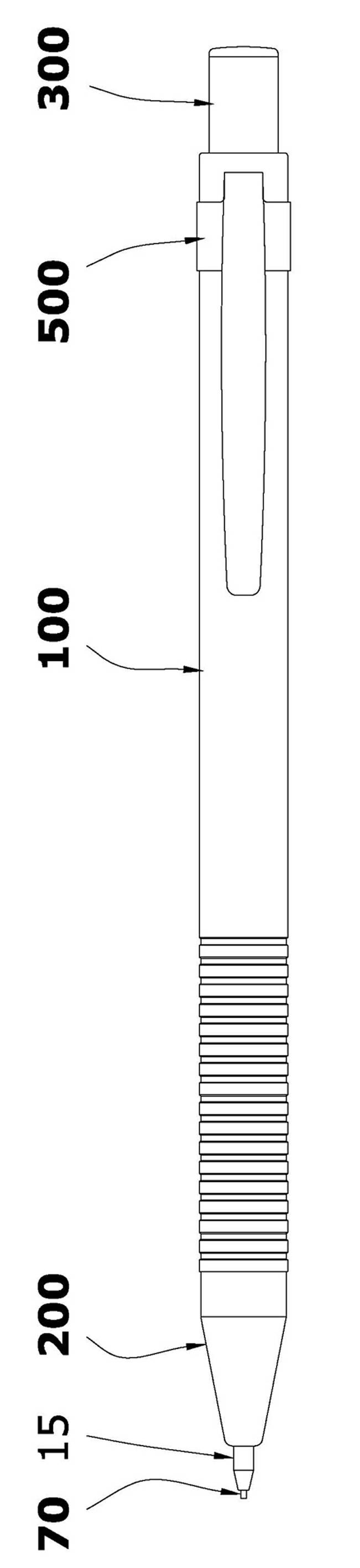

[0033] like Figure 8 and Figure 9 A micro-adaptive movement for a propelling pencil is shown, which is composed of a pointed sleeve 10, a spring seat 20, a locking hoop 30, a collet 40, a spring 50 and a core guide tube 60, as shown in FIG. Figure 10 and Figure 11 As shown, the installation method and working principle of the present invention assembled in the mechanical pencil are the same as the first embodiment. The difference between this embodiment and Embodiment 1 is that the damping part is a damping ring 11 that is set inside the tip sleeve 10, and a three-claw damping piece 11.1 is fixed in the damping ring 11. Sheath copper head 15 ; Other structures, assembly relations and working principles of the present invention are the same as in Embodiment 1.

[0034] The structures of the above-menti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com