Broken yarn processing device of ring spinner

A technology of a ring spinning machine and a processing device, which is applied to textiles and papermaking, etc., can solve the problems of crowded position, inconvenient operation, and inconvenient operation by workers, and achieves the effect of a reasonable device structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

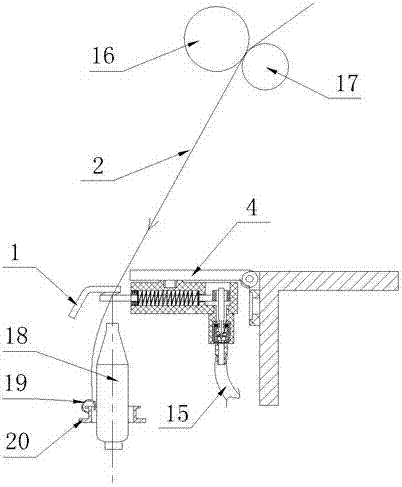

[0030] Such as figure 1 As shown, in the ring spinning machine, the roving 27 enters the holding area formed by the back roller 24 and the back top roller 25 through the yarn guide 26, and guides the holding area between the middle roller 22 and the middle top roller 23, and then Guided to the holding area of the front roller 17 and the front top roller 16, multi-pass drafting and twisting to form the yarn 2, the yarn guide hook 1 is installed under the front roller 17 and the front top roller 16, with a steel collar 20 The bobbin 18 is installed under the yarn guide hook 1 , and the traveler 19 is installed on the ring ring 20 . The yarn 2 drafted and twisted by the front roller 17 and the front top roller 16 passes through the yarn guide hook 1, guides in the traveler 19 on the ring ring 20, and is finally wound on the bobbin 18.

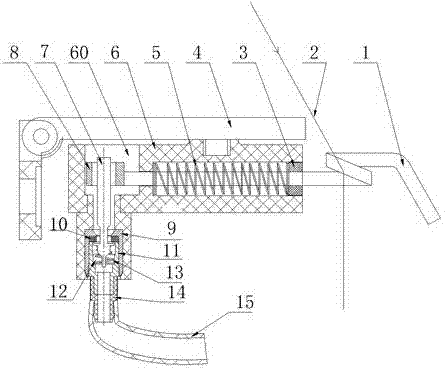

[0031] combine figure 2 , Figure 6 As shown, the air valve switch is installed on the straight handle end of the yarn guide hook 1, includ...

Embodiment 2

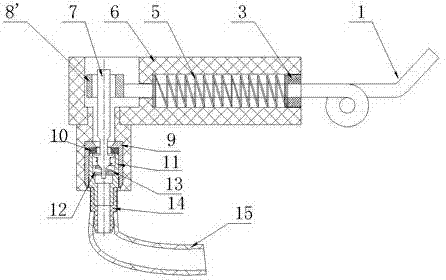

[0038] Such as image 3 , Figure 3-1 As shown, the structure and working principle are the same as in Embodiment 1, the difference is that the limit block 8' is annular, and the valve stem and the flap are parallel.

Embodiment 3

[0040] Such as Figure 4 , Pic 4-1 As shown, the structure and working principle are the same as in Embodiment 1, the difference is that the limiting block 8-1 is wedge-shaped with an inclined surface, and its inclined surface is facing downward, against the upper part of the valve stem, and the valve stem and the flap are in a parallel state.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com