All-hydraulic tunnel inverted arch trestle-type moving die frame

A mobile formwork and full hydraulic technology, which is applied in tunnels, tunnel linings, shaft equipment, etc., can solve the problems of difficulty in walking the inverted arch mobile formwork, difficulty in obtaining effective guarantees, labor-intensive positioning of the fixed and curved formwork, and formwork removal. Achieve the effects of improving utilization rate and construction standardization, reducing manual handling time, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

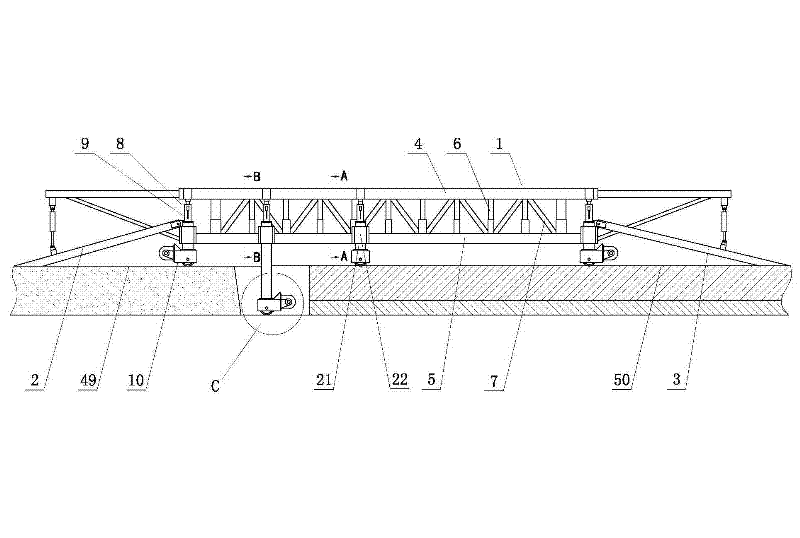

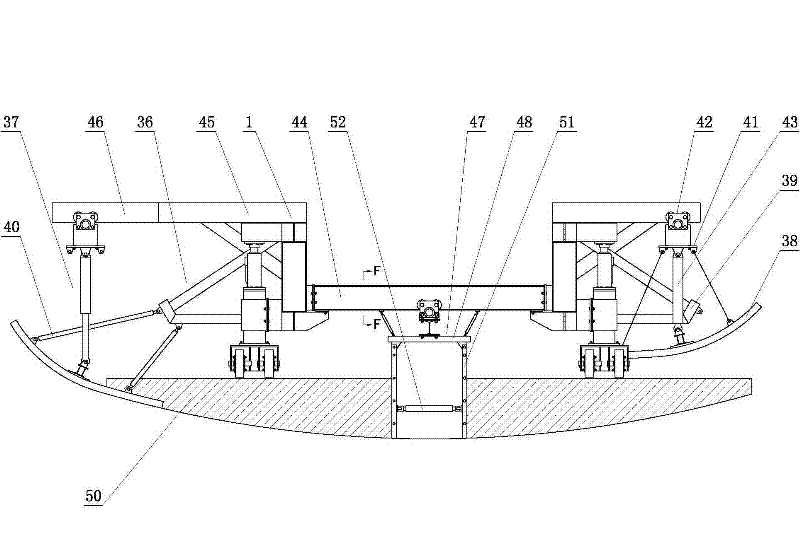

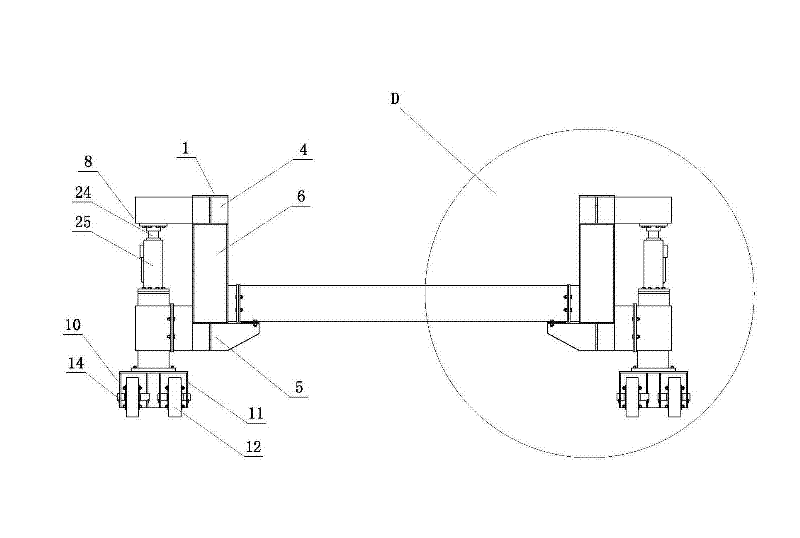

[0019] see figure 1 , image 3 ( figure 1 Show the front view situation of the present invention, image 3 Yes figure 1 Partial sectional view of middle A-A), the full-hydraulic tunnel inverted arch trestle type mobile formwork of the present invention includes a main bridge 1, a front slope bridge 2, and a rear slope bridge 3, and the main bridge includes a top beam 4 and a bottom beam 5 arranged horizontally , a vertical support beam 6 arranged vertically, and an oblique support beam 7 arranged obliquely (belonging to the prior art). From front to back on the main bridge ( figure 1 (From left to right in the middle) is provided with a plurality of straddling running devices 8; In this embodiment, four straddling running devices are arranged on the main bridge, which are respectively arranged at the front end, the rear end and the front part of the main bridge. The straddling walking device includes a pair of height adjustment mechanisms 9 and a pair of walking mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com