Gravity grading stone removing machine

A technology of gravity grading and stone removal machine, which is applied in the direction of solid separation, separation of solids from solids by air flow, and sieving, etc., can solve the problem that stone removal machine products cannot meet the needs of the market, and achieve good stone removal effect. , good performance, high quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

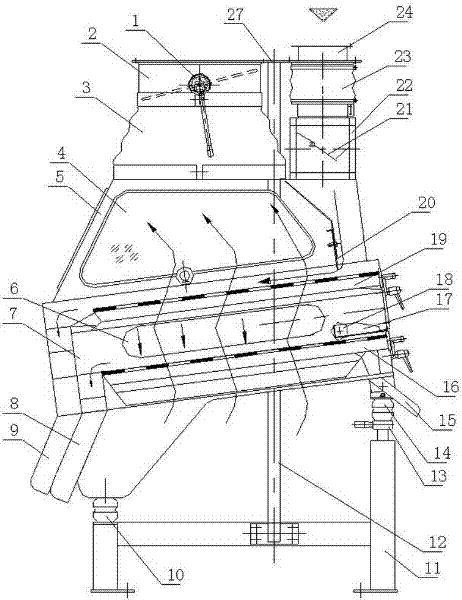

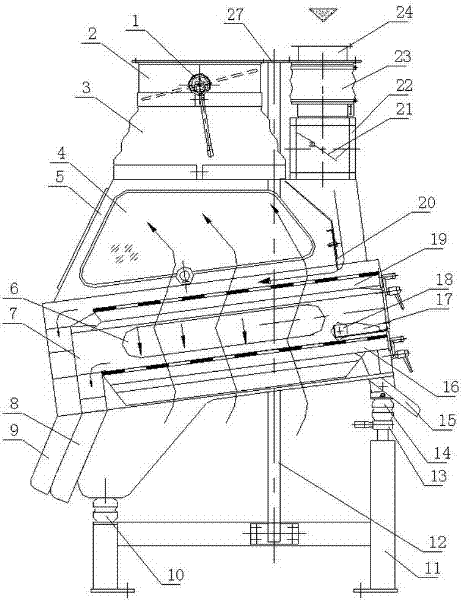

[0021] Such as figure 1 , 2 As shown, it is a gravity grading destoner, comprising a frame 11, a sealed vibrating body 7 is arranged above the frame 11, a third observation window 6 is arranged on the vibrating body 7, and the two sides of the front end of the vibrating body 7 are connected to the frame 11. The first rubber spring 14 and the adjustment screw 13 are arranged respectively between them, and each adjustment screw 13 is arranged under the corresponding first rubber spring 14 respectively, and each adjustment screw 13 is threadedly connected with the frame 11 respectively, and the rear end of the vibration body 7 Second rubber springs 10 are respectively arranged between the two sides and the frame 11 , and vibration motors 25 are respectively arranged on both sides of the rear end of the vibrating body 7 . The vibrating body 7 is provided with an upper sieve 19 and a lower sieve 16. A light material outlet 9 is arranged below the vibrating body 7 at the rear end o...

Embodiment 2

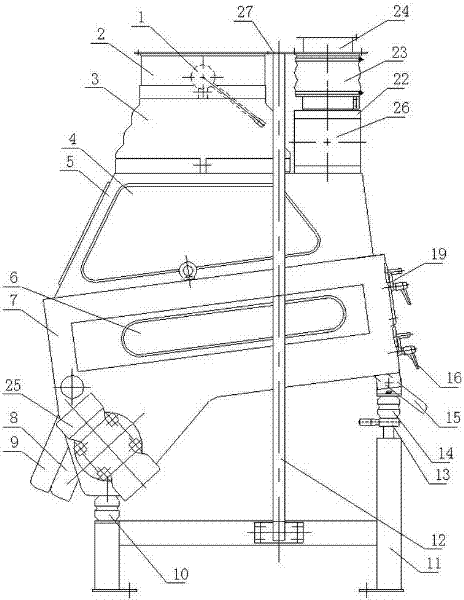

[0024] Such as image 3 , 4 As shown, it is a duplex gravity classification destoner, including a frame 11, a sealed vibrating body 7 is arranged above the frame 11, and vibrating motors 25 are respectively arranged on both sides of the rear end of the vibrating body 7. The vibrating body 7 is provided with an upper sieve 19 and a lower sieve 16. A light material outlet 9 is arranged below the vibrating body 7 at the rear end of the upper sieve 19. A heavy material outlet 8 is arranged under the vibrating body 7 at the rear end of the lower sieve 16. The front end of the lower sieve 16 is An air regulating plate 17 is arranged above, and the air regulating plate 17 is connected with the vibrating body 7 through a handle 18, and a rock outlet 15 is arranged below the front end of the vibrating body 7.

[0025] Two air chambers 5 are connected above the vibrating body 7, and a second observation window 4 is respectively set on each air chamber 5, and a rubber hose 3 and a feed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com