Cutting blade saw and manufacturing method thereof

A blade and cutting machine technology, which is applied in the cutting tool manufacturing, tool manufacturing, application and other directions of the sawing machine device, can solve the problems of poor cutting performance, smaller area, and the blade 106 falls off, and achieves wear inhibition, good cutting performance, and inhibition of falling off. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments for carrying out the present invention will be described in detail below based on the drawings.

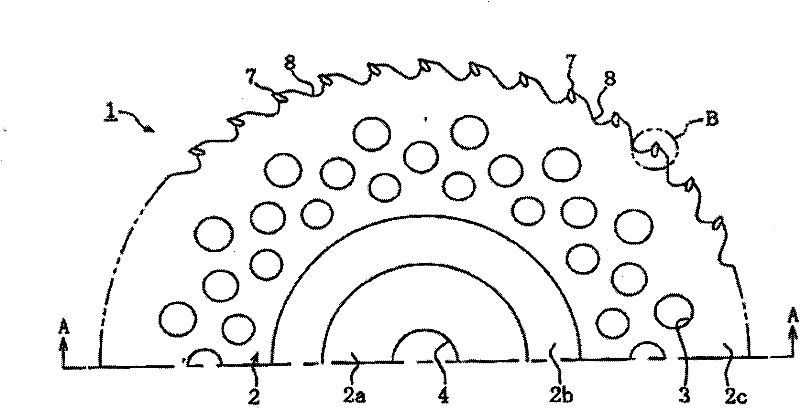

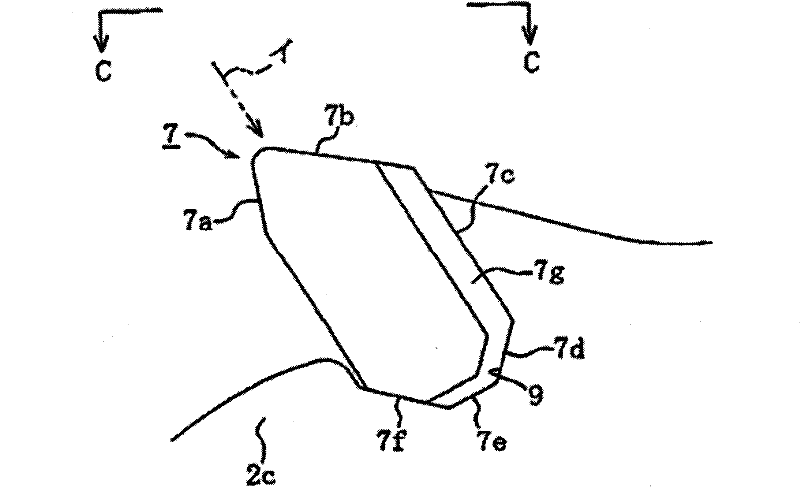

[0033] Figure 1 to Figure 7 This is an embodiment of the cutting blade saw according to the present invention. like figure 1 and figure 2 As shown, the blade saw 1 for cutting (become the blade saw 1) is provided with a disc-shaped base metal disk 2 with a plurality of lightweight holes 3 formed therein, and at the center of the base metal disk 2 is formed a 5 Mounting holes 4 for installation.

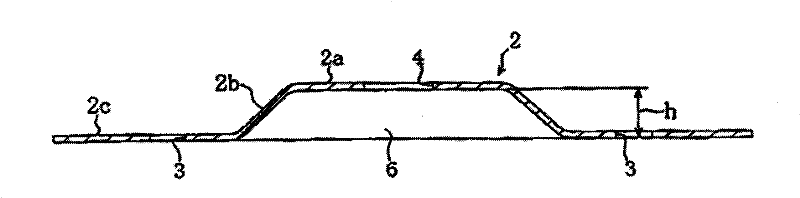

[0034] In addition, the base metal disk 2 has a flat portion 2a of a predetermined width formed on the outside of the mounting hole 4; figure 2A step portion 2b protruding in a downward oblique direction with a height h is formed on the outside of the step portion 2b, and a flat blade portion 2c is formed. Then, on the base metal disk 2, a circular space-shaped concave portion 6 viewed from the step portion 2b to its inner side is formed, and at the same time, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com