Robot having arm in which umbilical member is accomodated

A robot and pipeline technology, applied in the field of robots, can solve problems such as the inertia of the wire feeding device and the balance of the arm structure that cannot be ruled out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

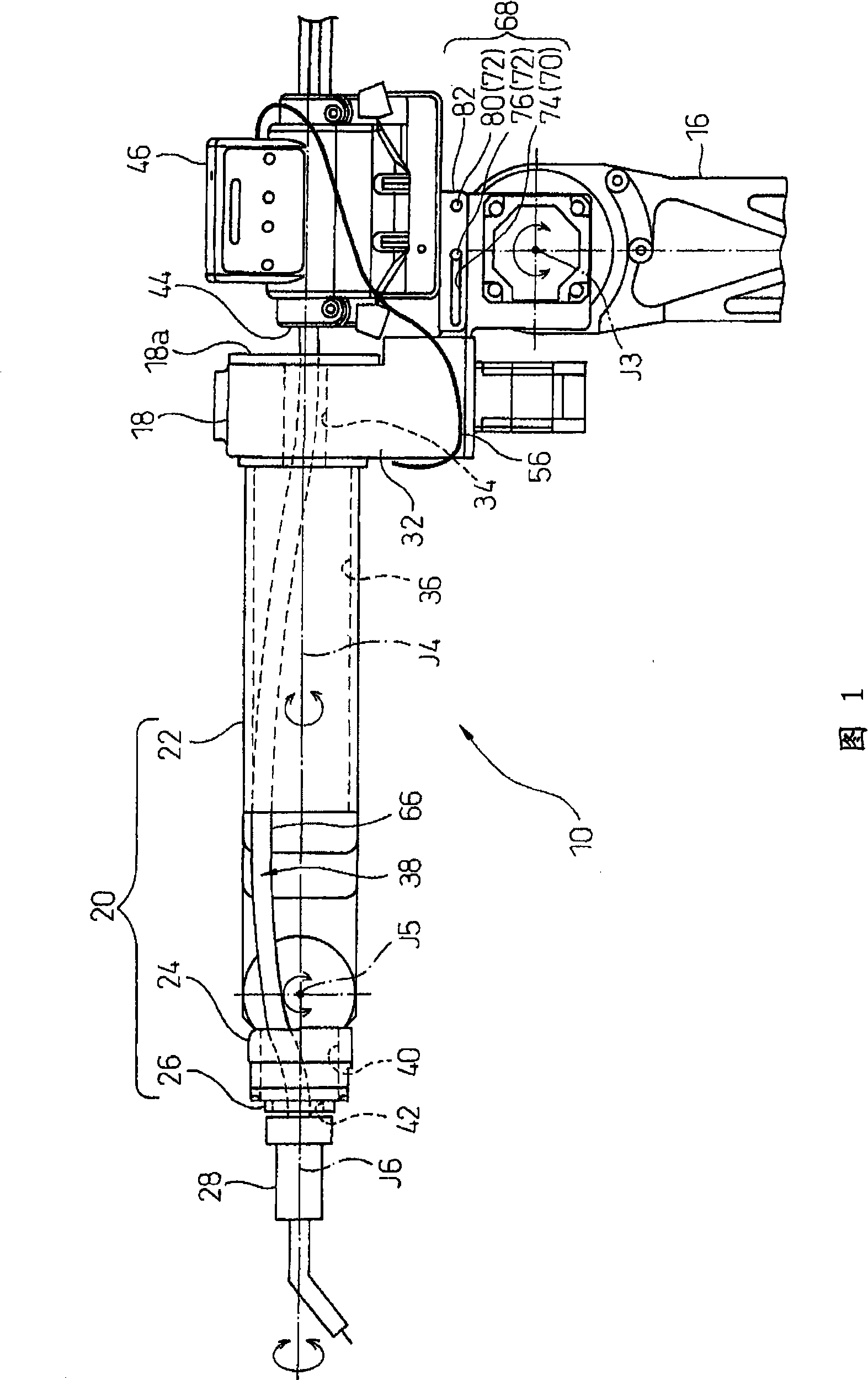

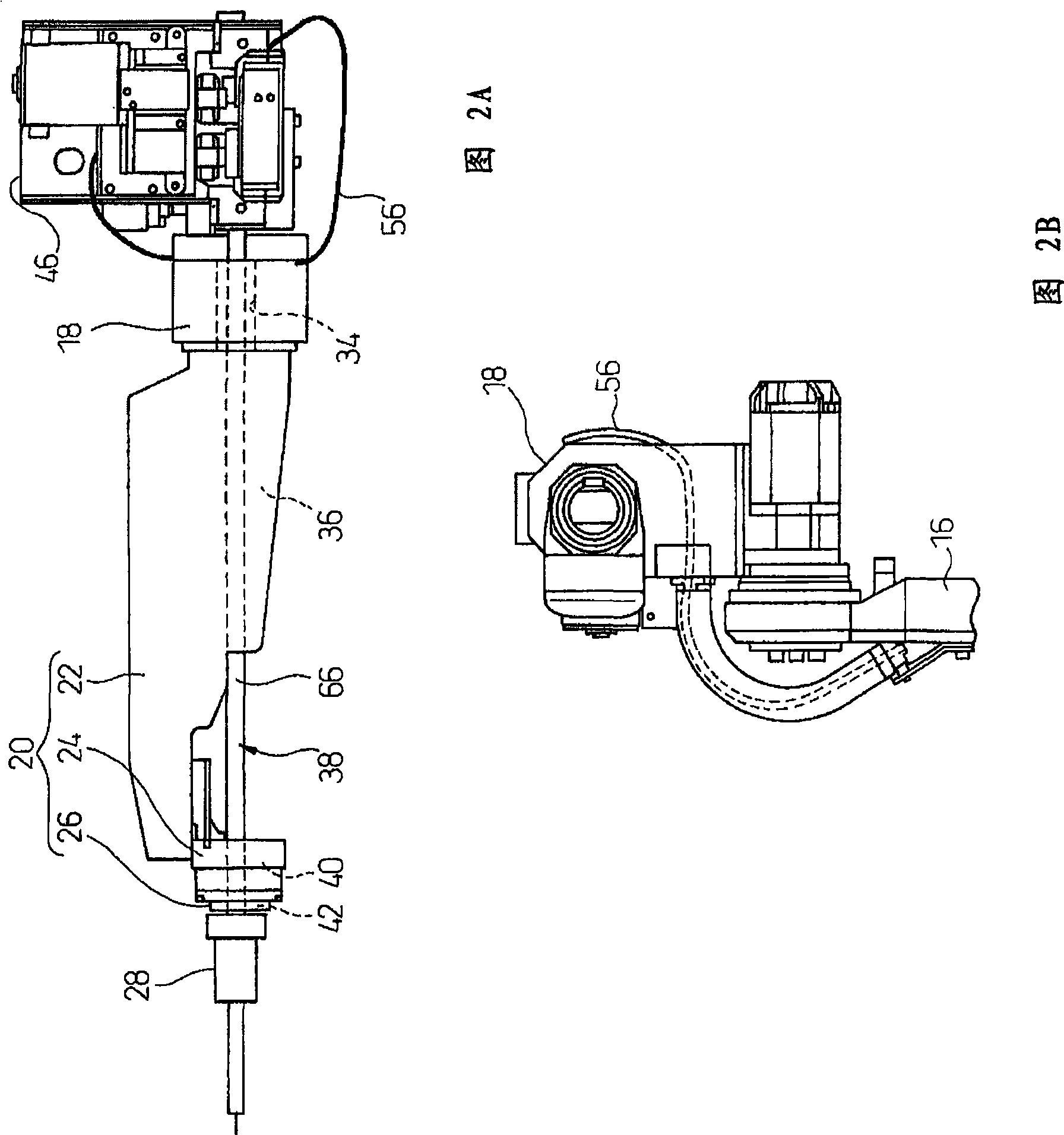

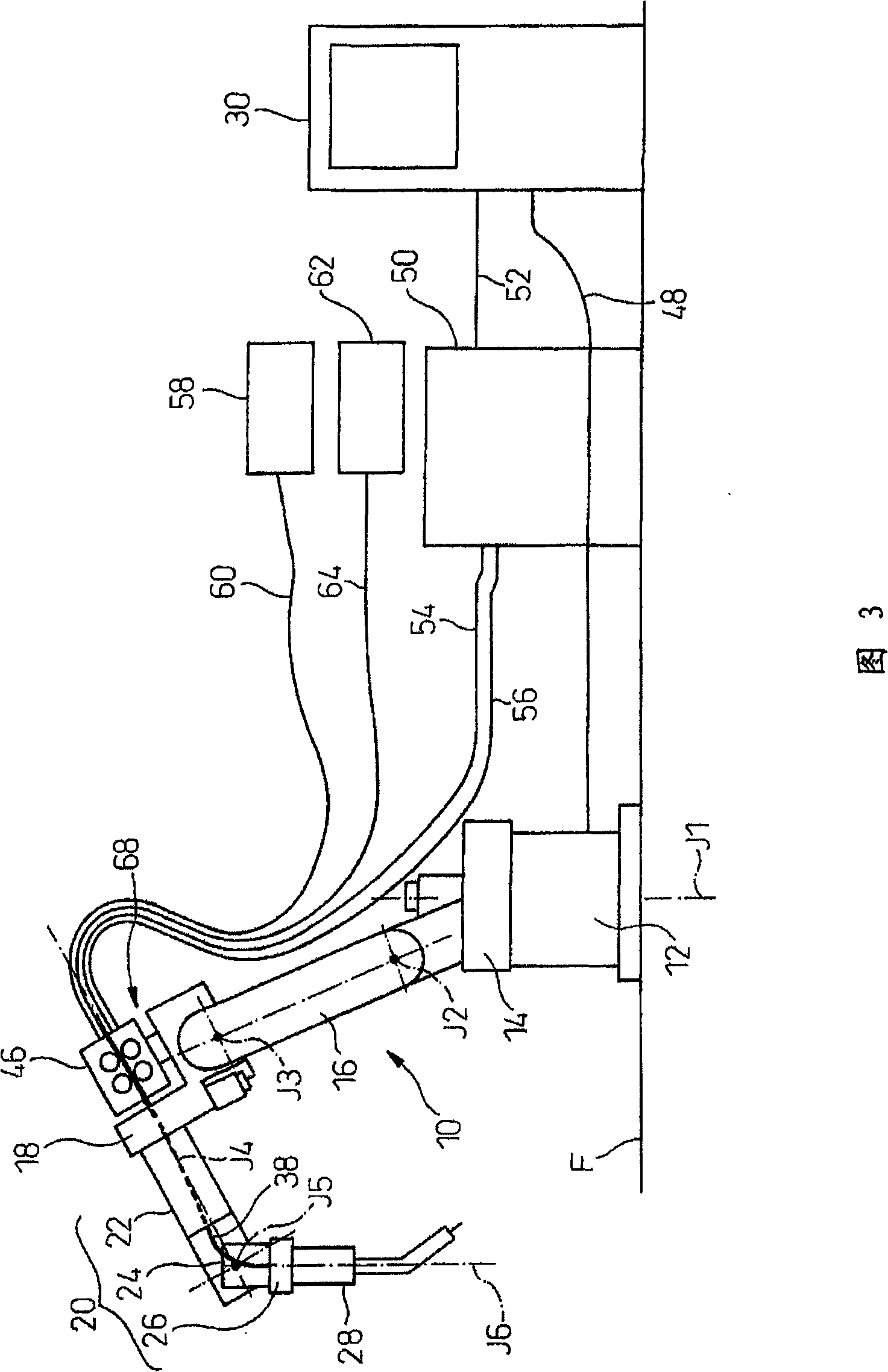

[0029] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. In the drawings, the same or similar structural elements are marked with common reference numerals.

[0030] Referring to the drawings, FIGS. 1 to 2B show main parts of a robot 10 according to an embodiment of the present invention. Moreover, FIG. 3 schematically shows an example of the overall configuration of the robot system including the robot 10. The illustrated robot 10 has a 6-axis vertical multi-joint type mechanical structure, but the mechanical structure of the robot of the present invention is not limited to this. In addition, the term "robot" in the present application means a mechanism unit other than a control device.

[0031] The robot 10 has a six-degree-of-freedom arm structure (that is, a manipulator) supported on a stationary base 12 fixedly installed on the floor F (FIG. 3 ). This arm structure includes: a rotating table 14 rotatably connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com