Thermal head

A technology of thermal head and heating element, applied in the field of thermal head, can solve problems such as heat release deviation, resistance value deviation, uneven printing density, etc., achieve uniform heating, eliminate uneven density, and good printing results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, the wiring pattern of the individual electrodes of the thermal head in the embodiment of the present invention will be described. In addition, unless otherwise specified, the thermal head of the present invention has the same structure as the conventional structure described above.

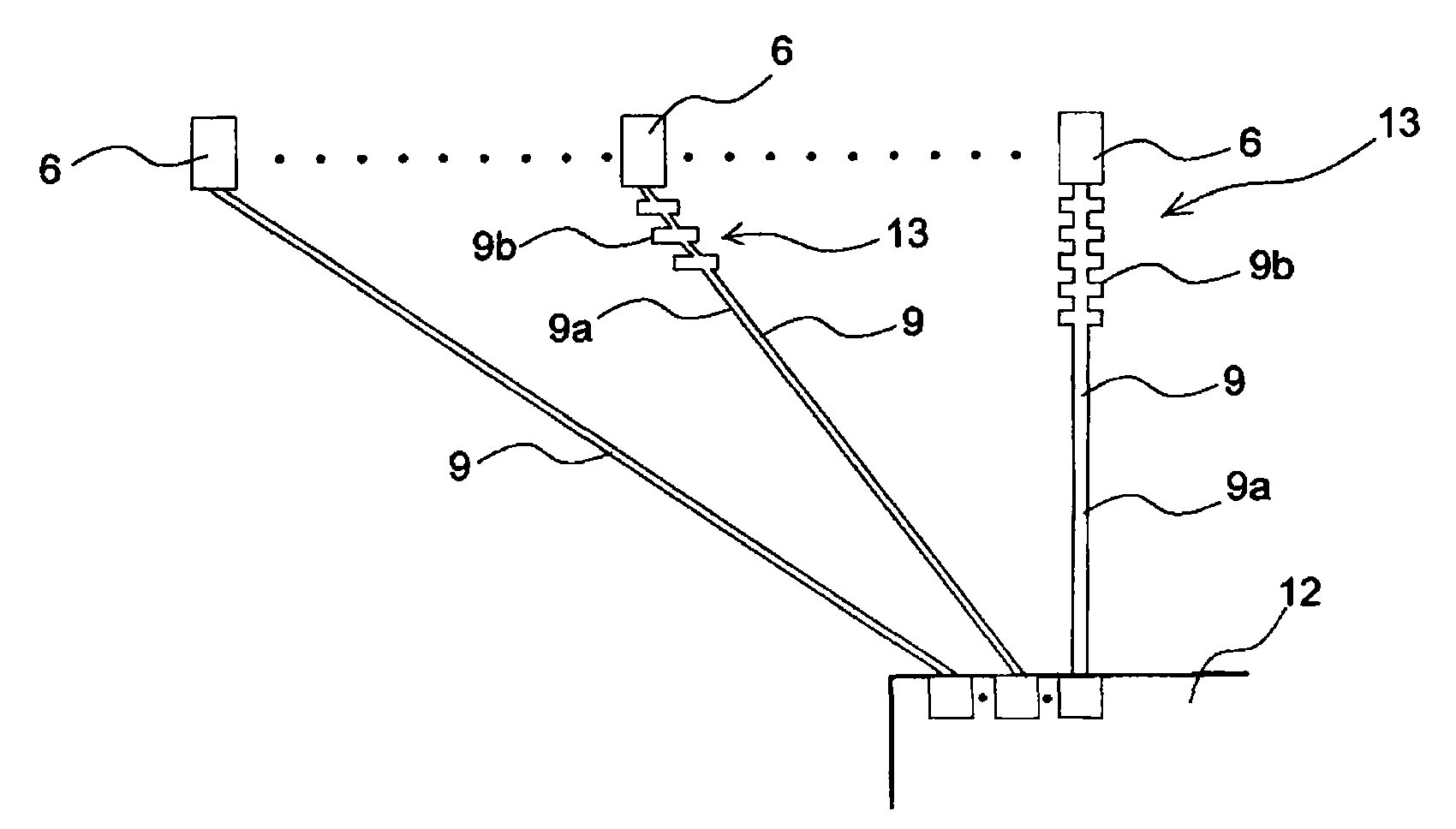

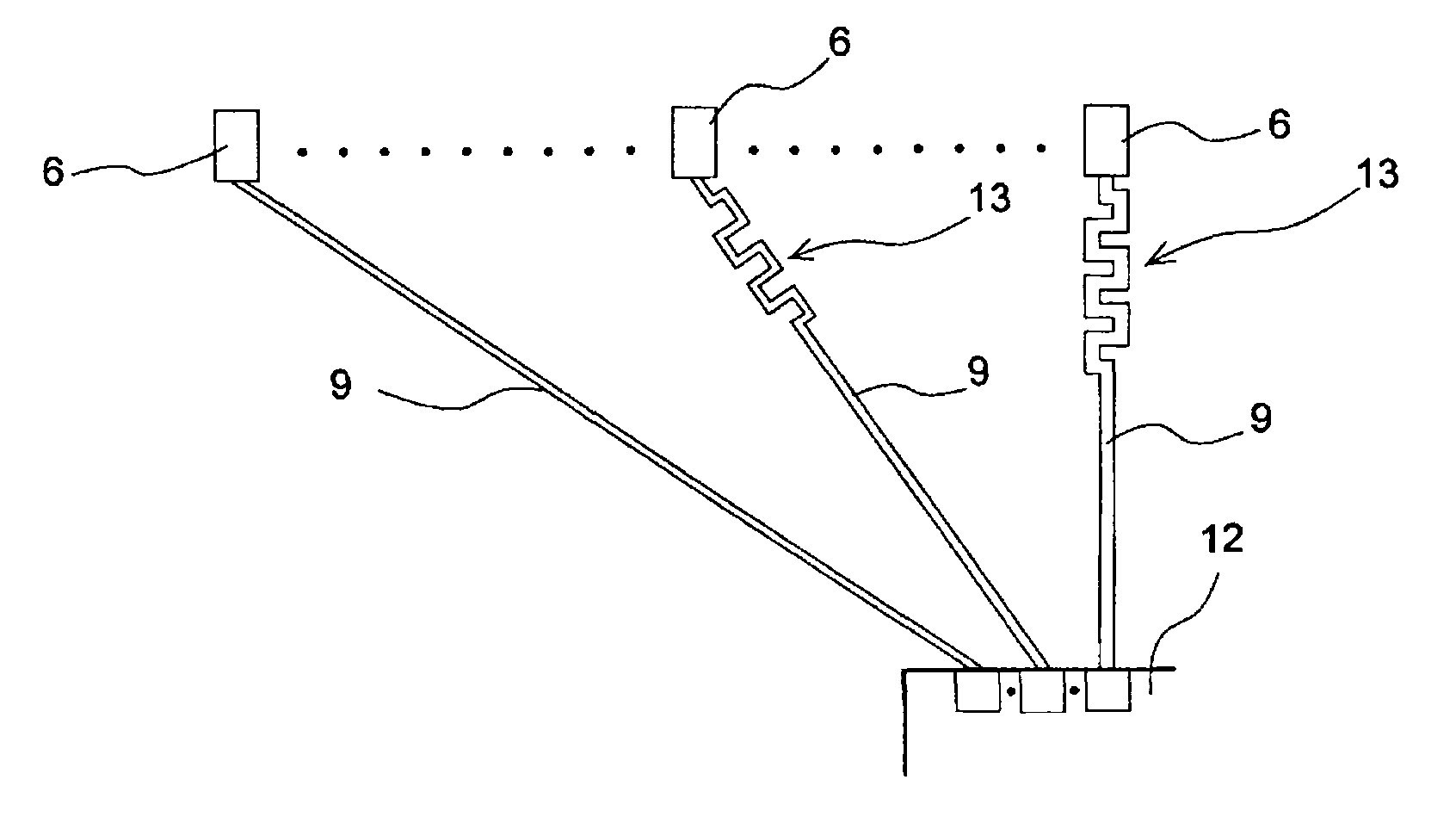

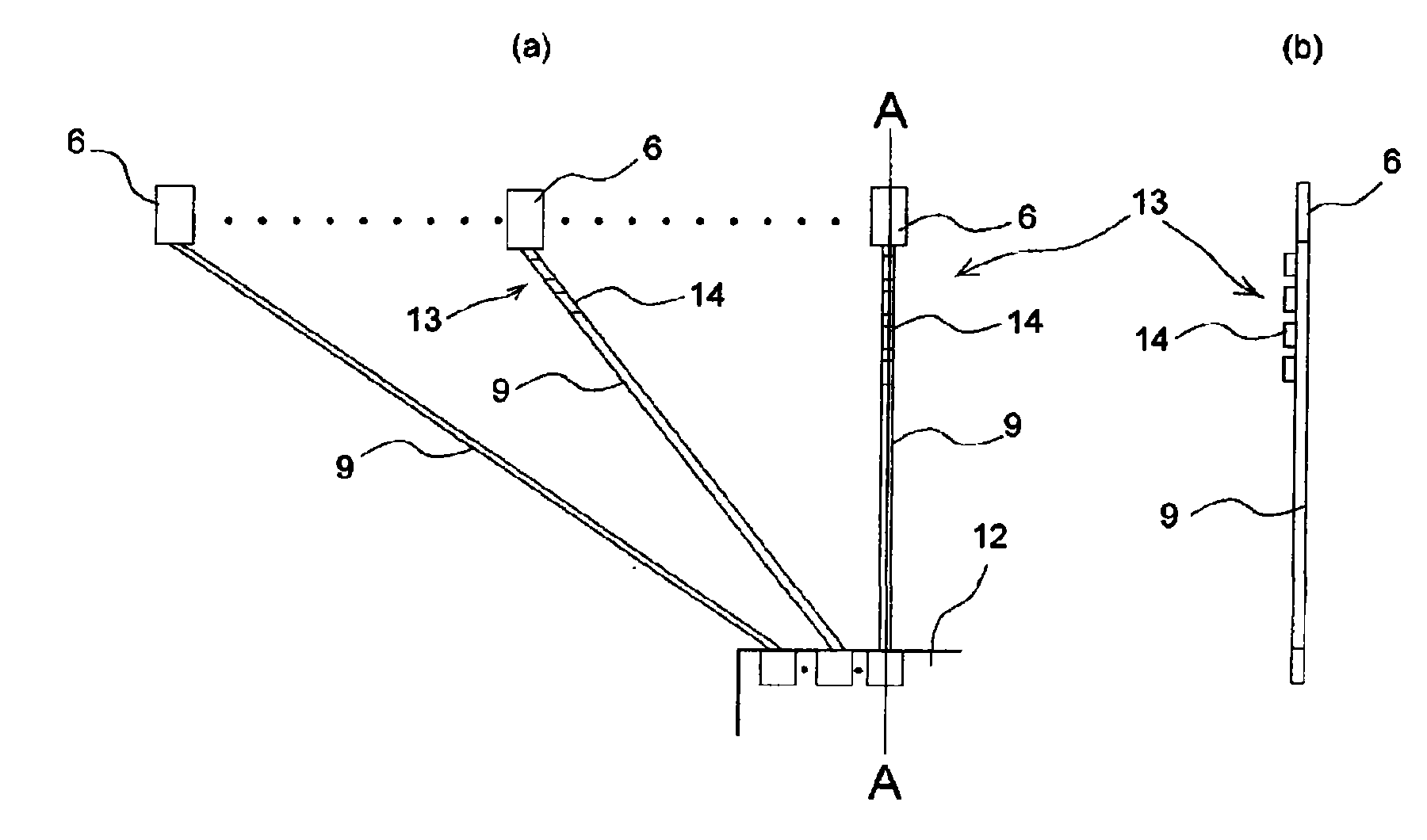

[0028] In the present embodiment, in the wiring pattern electrically connecting each heating element 6 and the individual electrodes 9 of the driver IC 12, there is formed a circuit for making the difference in capacity (volume) of the conductors of the individual electrodes 9 (hereinafter simply referred to as "capacity"). The capacity adjustment section 13 is adjusted so that the difference ") becomes smaller, and the wiring pattern of the above-mentioned individual electrodes 9 is formed so that the wiring resistance thereof is adjusted to be constant.

[0029] Specifically, as figure 1 As shown, in the main line 9a of the wiring pattern of the individual electrode 9 that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com