Knitting machine

A technology of knitting machines and components, applied in the field of sinkers, to achieve the effect of simple structure, small length and saving manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

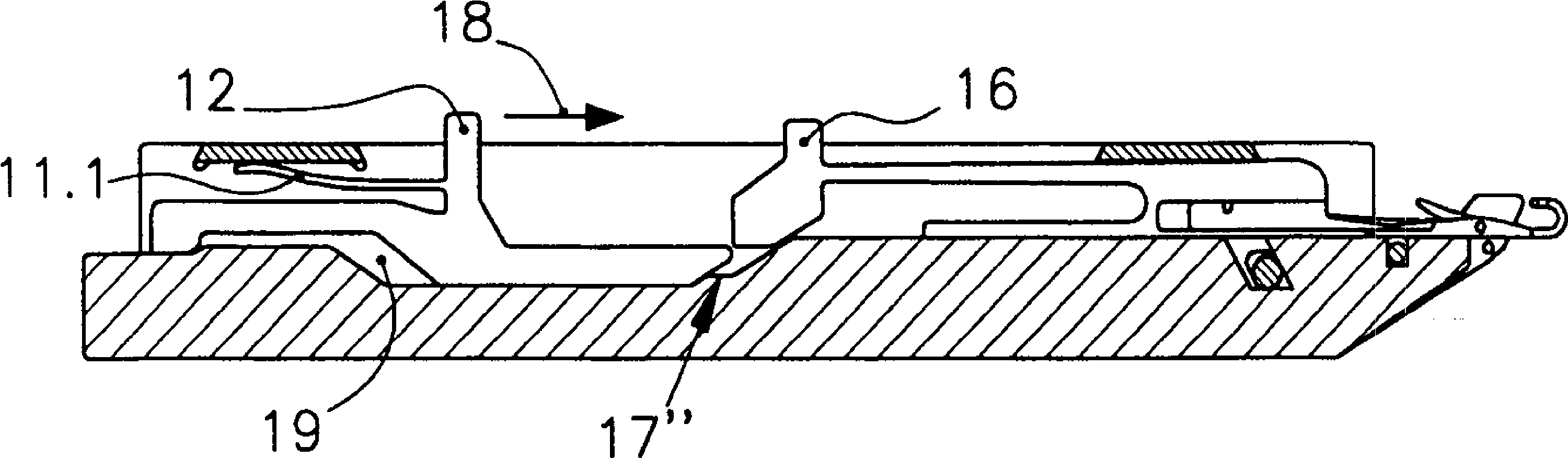

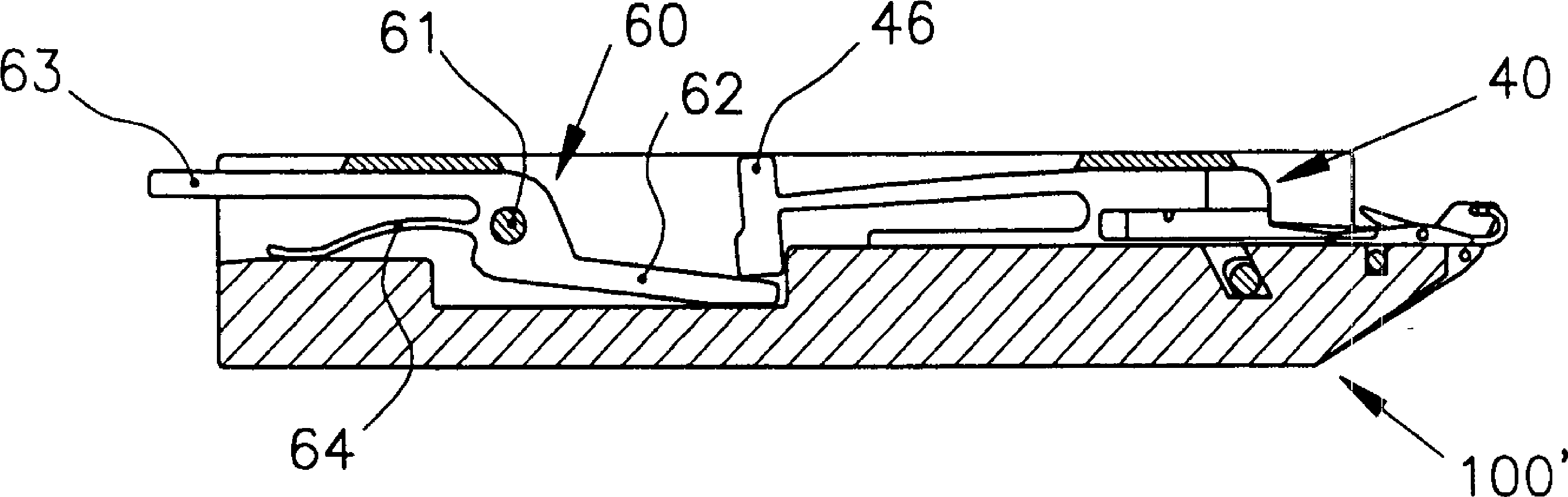

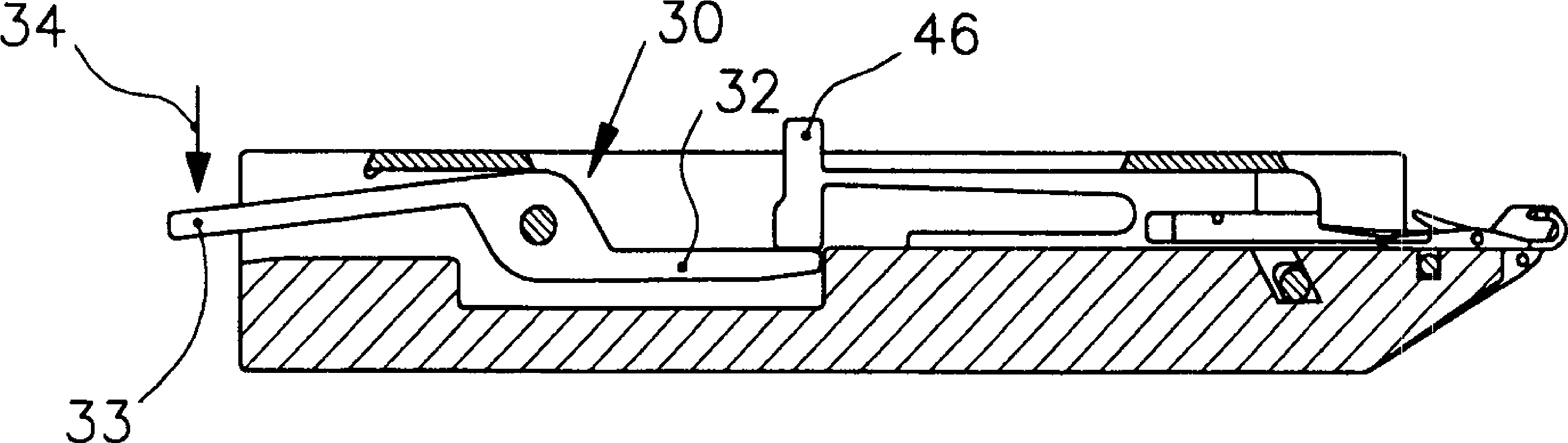

[0030] Figures 1a to 1f Both are sectional views of the functional component groove 110 region of the functional component 100 in which the functional component 10 designed as knitting needles and the sinker 11 are arranged. The cover rail 120 prevents the functional part 10 from coming out of the needle channel 110 together with its adjacent functional parts, and the cover rail 130 prevents the sinker 11 from coming out of the needle channel 110 together with its adjacent sinker. The functional component groove has a recess 19 in the functional component substrate 115 . The sinker 11 is supported on the cover rail 130 via the elastic member 11.1.

[0031] exist Figure 1a , both the functional part 10 and the sinker 11 are in their untouched initial position. The sinker 11 has been moved backwards by means of the positioning feet 12 . The needle hooks 13 of the functional part 10 are in an evenly aligned position (Kammgleeche position). In its rear region, the functiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com