Line pipe structure for bicycle

A bicycle and wire tube technology, which is applied in the field of bicycle wire tube structure, can solve the problems of ductility discount, elbow aging, fatigue, etc., and achieve the effects of delaying aging, improving flexibility, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

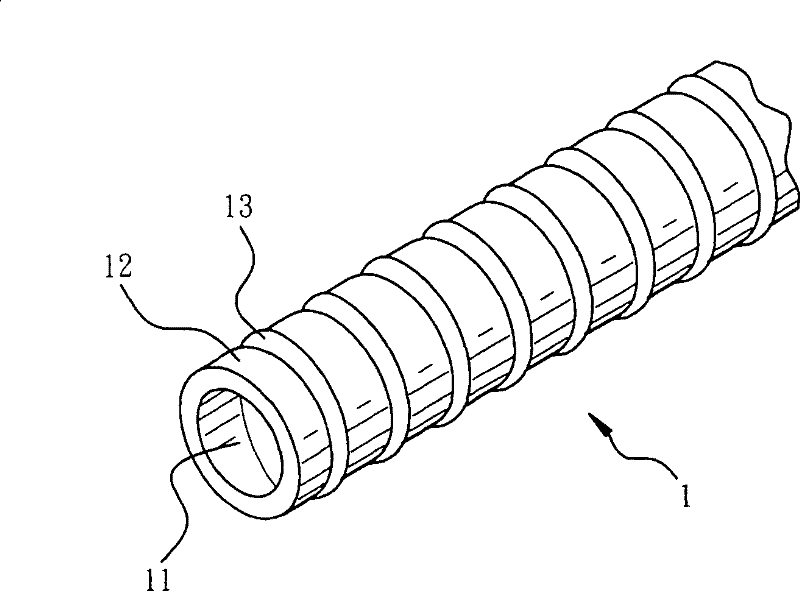

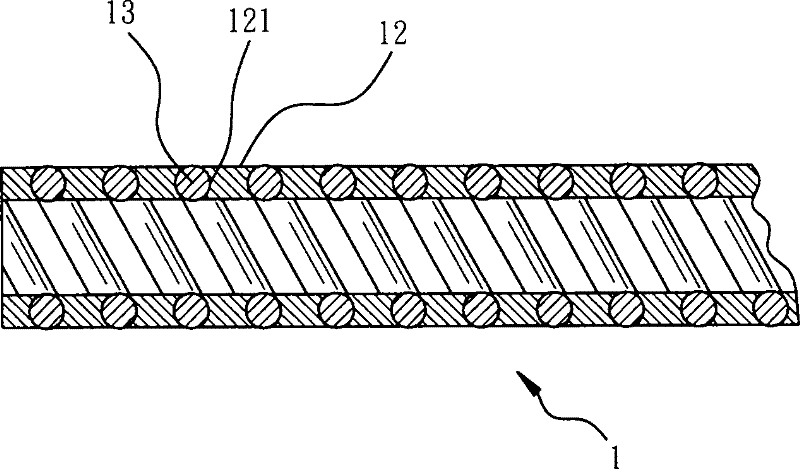

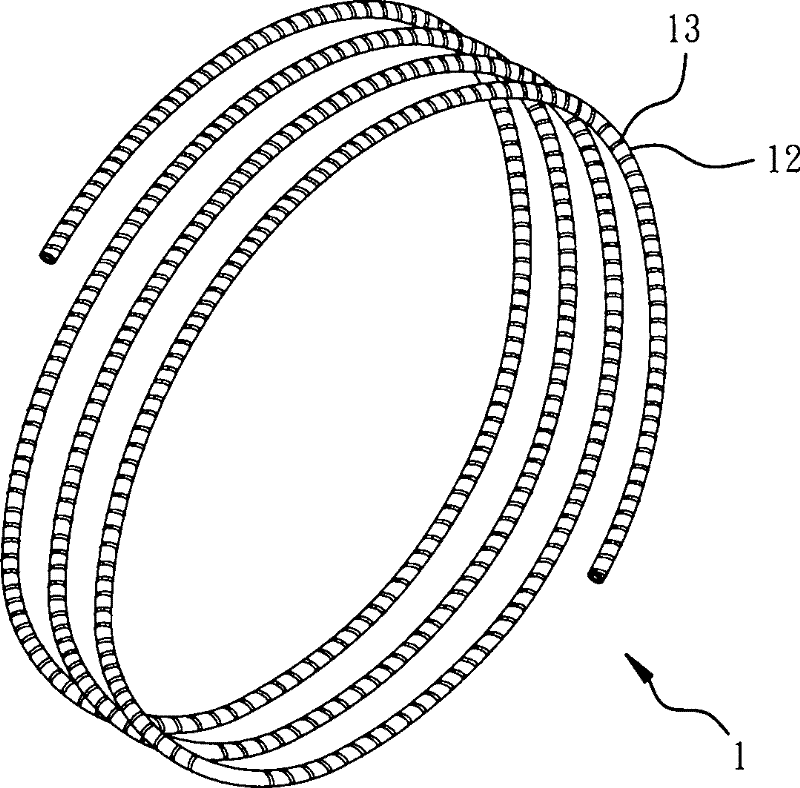

[0023] The invention relates to a bicycle cable structure, which is a bicycle cable structure with both flexibility and ductility. When bicycle brake cables, shift cables and other cable bodies are assembled, they can pass through the cable structure. Provides more variable flexibility adjustments and more flexible extension settings, please refer to Figure 1 to Figure 3 As shown, the "bicycle wire tube structure" of the present invention is a wire tube body 1;

[0024] The central part of the wire pipe body 1 has a wire groove 11 for passing through the bicycle brake wire or the transmission wire. The wire pipe body 1 is composed of a hard metal layer 12 and a flexible metal layer 13, and the hard metal layer 12 And the flexible metal layer 13 is in an overlapping state, gradually surrounding the wire pipe body 1, the wire pipe body 1 can achieve the effect of bending and shaping through the flexible metal layer 13, and can also pass through the rigid The metal layer 12 enh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com