System and method for controlling combustion of mechanical grate incinerator

A mechanical grate and control system technology, applied in the direction of combustion method, combustion type, incinerator, etc., can solve the problems of atmospheric and human hazards, affecting the power generation of environmental protection emission indicators, and the power generation of generator sets that cannot reach environmental protection, etc. Achieve the effect of reducing cost and expenditure and excellent combustion control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

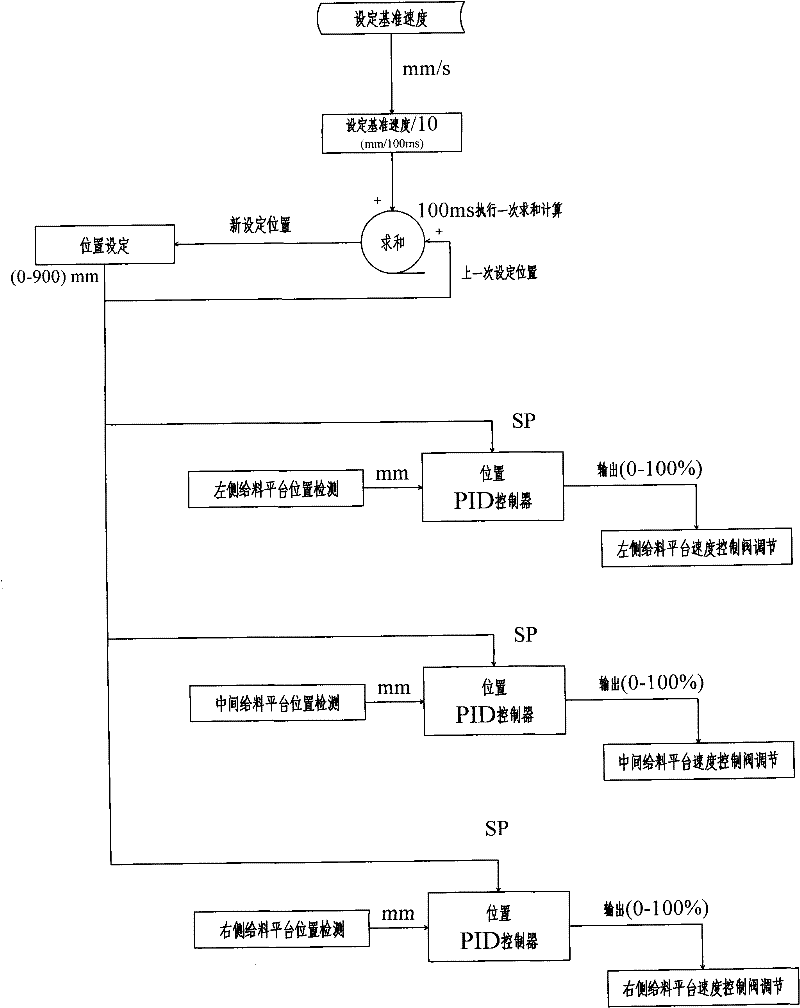

[0076] As an implementable manner, the adjustment process of the PID controller is:

[0077] U(n)=Kp*E(n)+Kp*T*∑E(i) / Ti+KP*Td*(E(n)-E(n-1)) / T+U0

[0078] in:

[0079] U(n) is the output value of the PID controller, that is, to adjust the opening of the control valve;

[0080] Kp is the P parameter value of the PID controller; E(n) is the deviation value, that is, the difference between the given value of the PID controller and the adjusted process parameter;

[0081] T is the PID controller adjustment cycle time;

[0082] ∑E(i) is the cumulative value of the deviation of the PID controller;

[0083] Ti is the I parameter value of the PID controller; Td is the D parameter value of the PID controller;

[0084] E(n-1) is the deviation of the last adjustment cycle of the PID controller;

[0085] U0 is the initial output value of the PID controller, which is generally 0. )

[0086] The control method of the feeding grate control system is described in detail below:

[0087]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com