Rotary brush for floor cleaner and base assembly of floor cleaner using the rotary brush

A technology of cleaners and rotating brushes, which is used in cleaning floors, cleaning equipment, machine parts, etc., and can solve problems such as impossible removal, complexity, and overturning of the main body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings, but the same reference numerals will be assigned to the same parts as conventional ones, and detailed descriptions will be omitted.

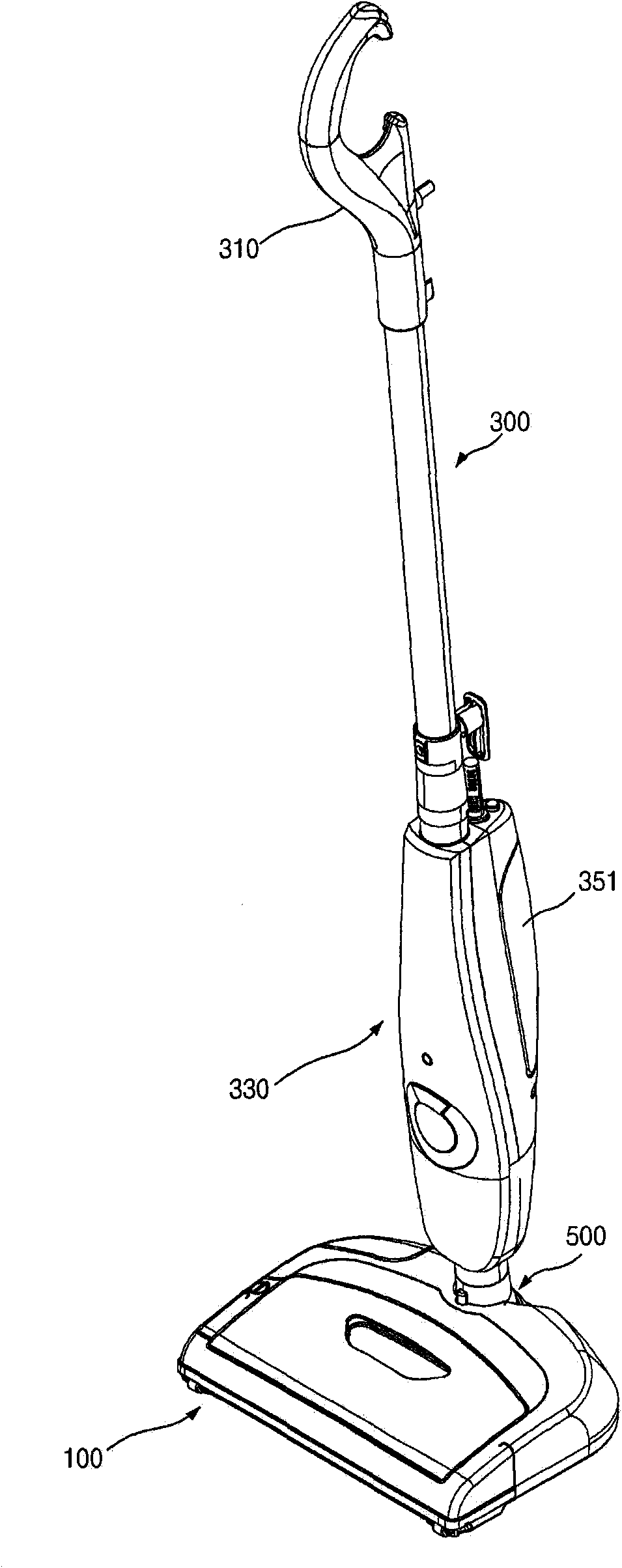

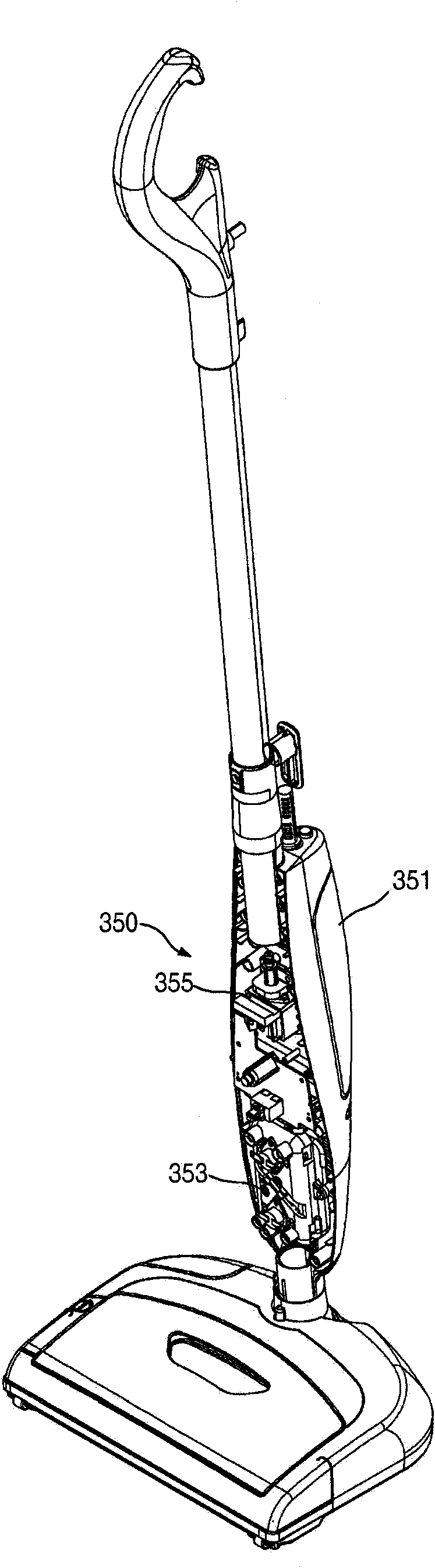

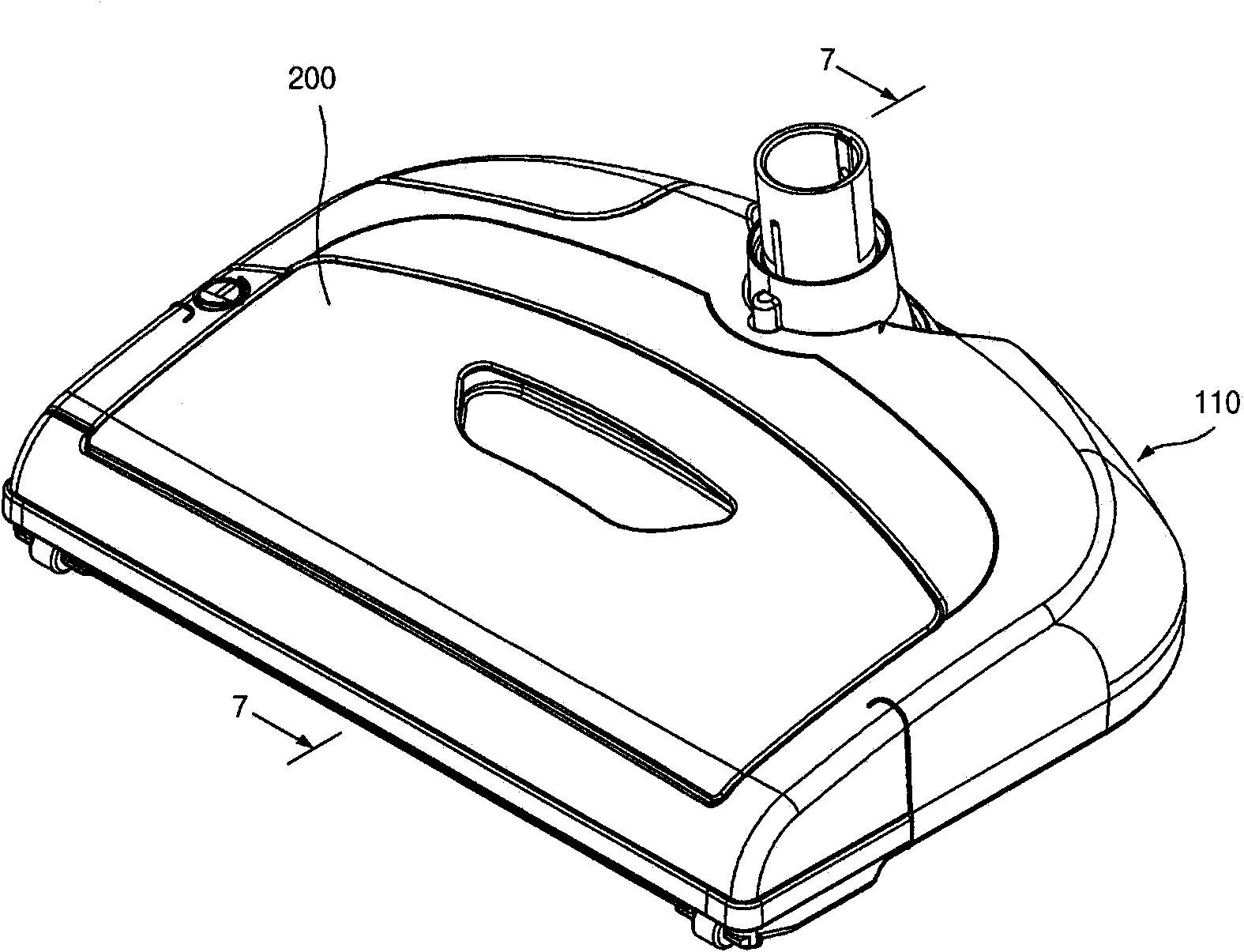

[0081] figure 1 It is a perspective view of a steam sweeper related to a preferred embodiment of the present invention, figure 2 for expressing figure 1 A perspective view of the instantaneous jet steam generating unit in , image 3 for figure 1 An enlarged perspective view of the base assembly of the, Figure 4 for from image 3 The three-dimensional view after separating the dust bucket, Figure 5 for from Figure 4 A perspective view after further separating the locking parts, Image 6 for image 3 The exploded perspective view of Figure 7 for along image 3 The sectional view seen on line 7-7, Figure 8 for image 3 The upward perspective view of Figure 9 is a perspective view of the bottom surface of the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com