Test sorting machine for battery product and sorting method for test sorting machine

A product testing and sorting machine technology, applied in the field of processing machinery, can solve problems such as low detection efficiency, error-prone, and low efficiency, and achieve high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

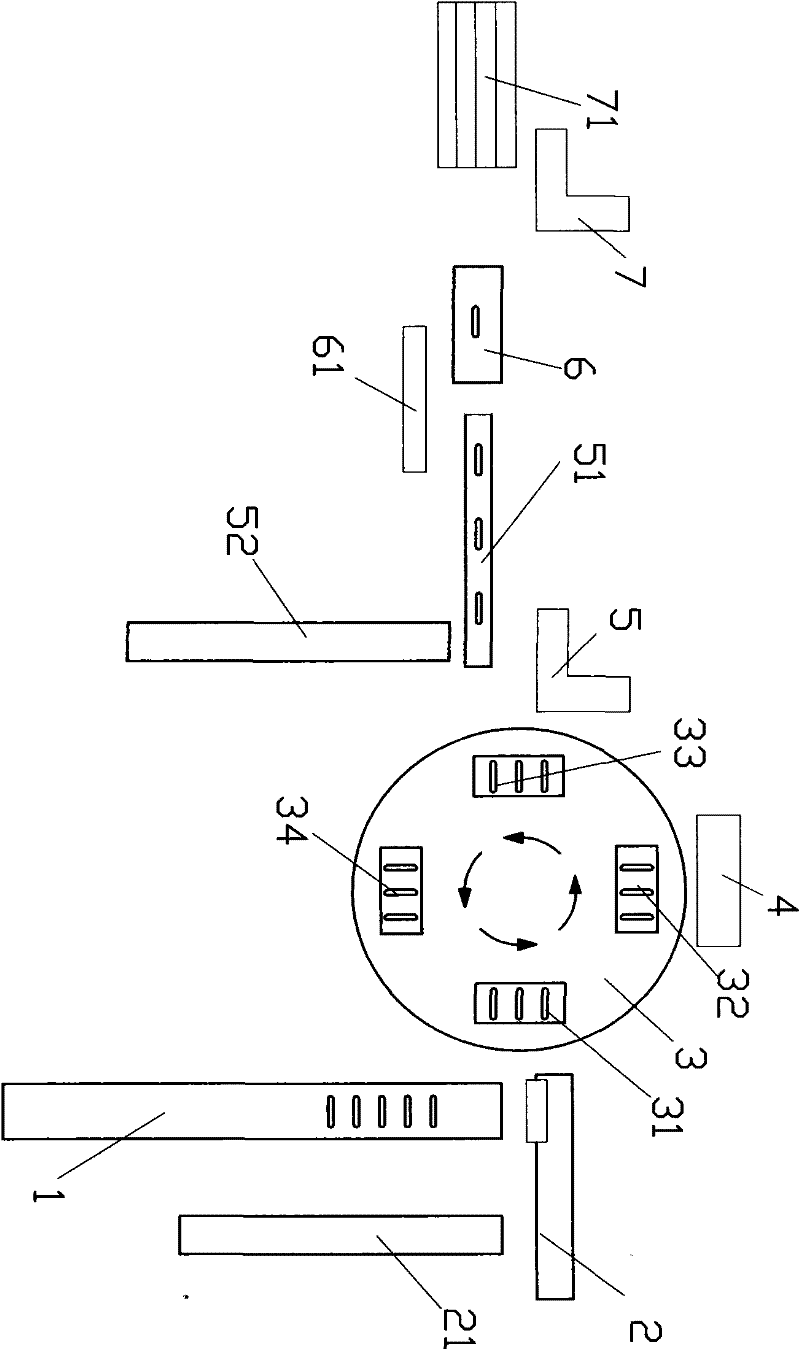

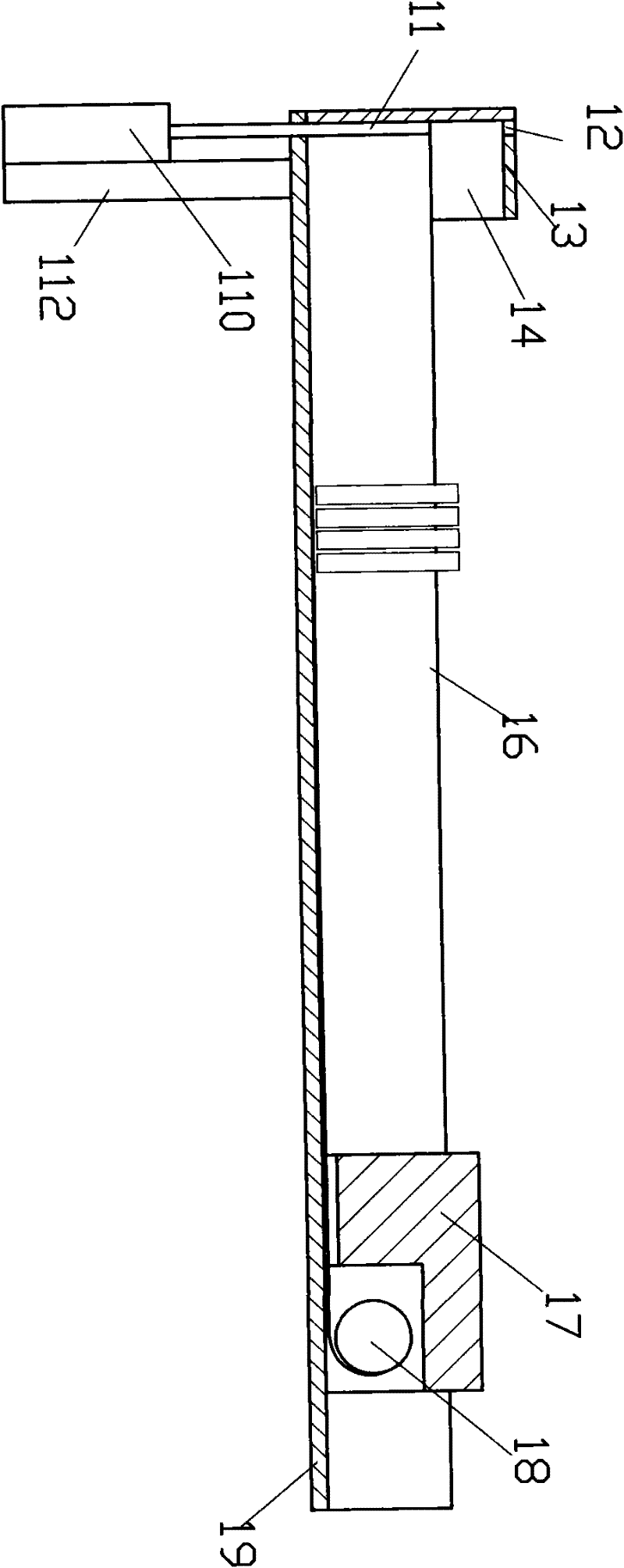

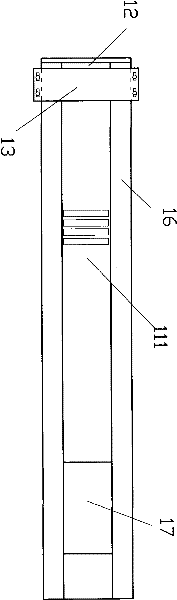

[0030] refer to figure 1 It can be seen that the present invention includes: a feeding device 1, a short circuit measuring and sorting device 2, a station turntable 3, a leak detecting device 4, a leak detecting and sorting device 5, a weighing device 6, a weighing and taking device 61, a weighing device The re-sorting device 7, wherein the station turntable 3 is provided with a short circuit qualified product placement station 31, a leak detection station 32, a leak detection and retrieving station 33, and a detection station 34, and each station is provided with a placement station The battery holder of the battery, the battery holder is provided with a group of slots for placing batteries side by side, one battery is placed in each slot, and each station is rotated 90 degrees to enter the next station, wherein a leak test station is set on the table on one side of the leak test station 32 Device 4, a short-circuit testing and sorting device 2 is set on the working table on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com