Pneumatic polishing reshaping device for spherical surface

A technology of shaping device and pneumatic grinding machine, which is used in spherical grinding machines, grinding machines, grinding/polishing equipment, etc., can solve the problems of gnawing or penetrating parts, unsuitable size control, low production efficiency, etc., to avoid potential safety hazards, The effect of ensuring dimensional consistency and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

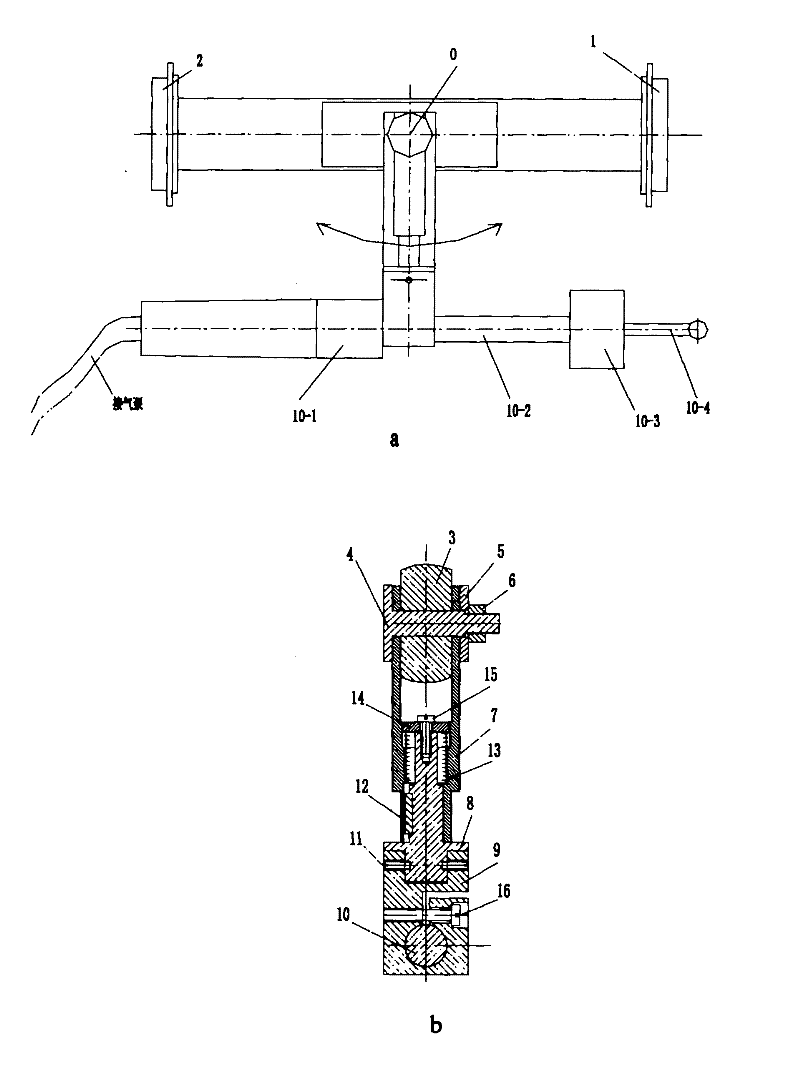

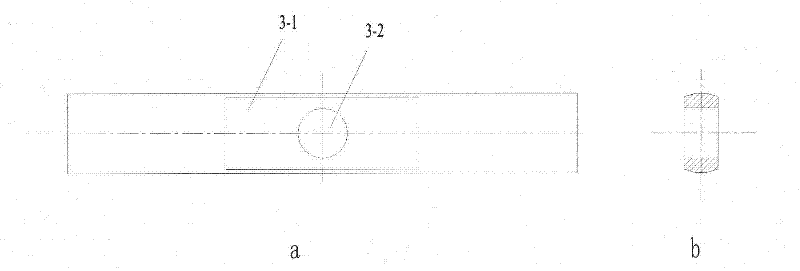

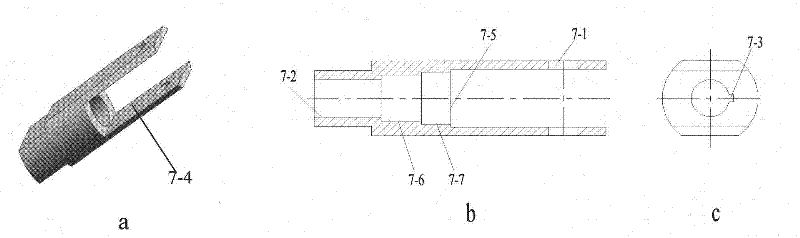

[0018] according to figure 1 As shown, the pneumatic spherical grinding and shaping device of the preferred embodiment of the present invention includes a first end cover 1, a second end cover 2, a horizontal shaft 3, a mandrel 4, a first vertical shaft 7, a second vertical shaft 8, an elastic sleeve 9, a pneumatic Sander 10, key 12 and spring 13. Both the first end cover 1 and the second end cover 2 are cylinders with a positioning shaft hole and two stepped outer circles, the dimensions of the two stepped outer circles match the positioning holes at both ends of the processed shell. The horizontal axis 3 is a cylinder and the middle section 3-1 is flat, and the middle of the flat section 3-1 has an axis positioning hole 3-2 perpendicular to the planes at both ends (see figure 2 ). The first end cover 1 and the second end cover 2 are fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com