Photocatalytic method for preparing 3,4-dichloroaniline

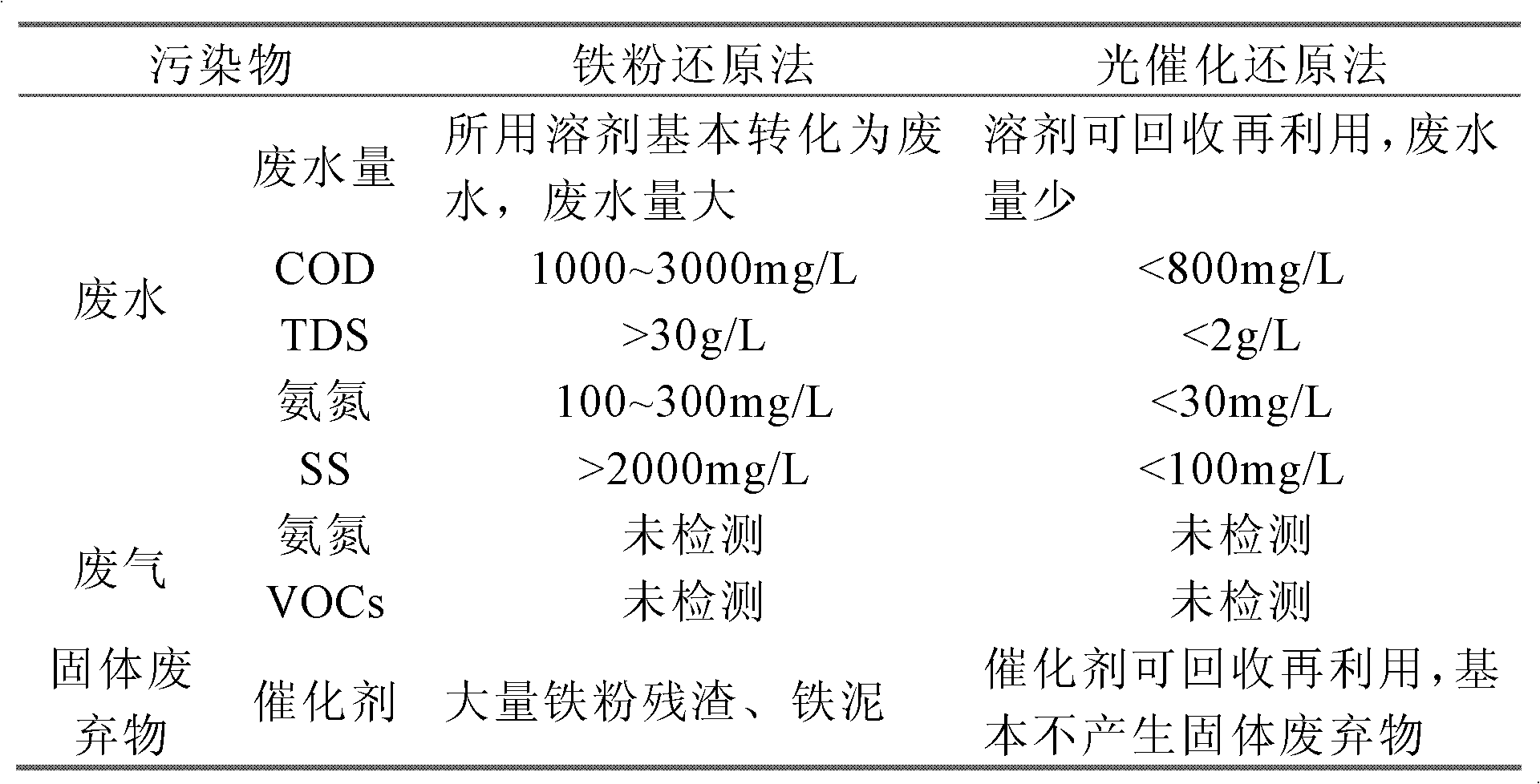

A technology of dichloroaniline and photocatalysis, applied in chemical instruments and methods, preparation of amino compounds, preparation of organic compounds, etc., can solve the high cost of alkali sulfide reduction method, large amount of three wastes in iron powder reduction method, and corrosion resistance requirements Advanced problems, to achieve the effect of low unit product cost, good environmental benefits, and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The photocatalytic method for preparing 3,4-dichloroaniline of the present invention is illustrated in conjunction with examples.

[0021] The photocatalytic method for preparing 3,4-dichloroaniline of the present invention is based on the following inventive idea: when the semiconductor used as a catalyst is irradiated with light having a wavelength smaller than the forbidden band width of the semiconductor, the electrons on the valence band of the semiconductor are excited to transition to the conduction band , creating holes in the valence band. Conduction band electrons have a strong reduction ability, which can reduce the electron acceptor adsorbed on the semiconductor surface, such as conduction band electrons, which can reduce the aromatic nitro substances adsorbed on the semiconductor surface. TiO 2 The 3,4-dichloronitrobenzene on the surface of the catalyst is reduced to 3,4-dichloroaniline.

[0022] Preparation of 3 of the present invention, the reaction rou...

Embodiment 1

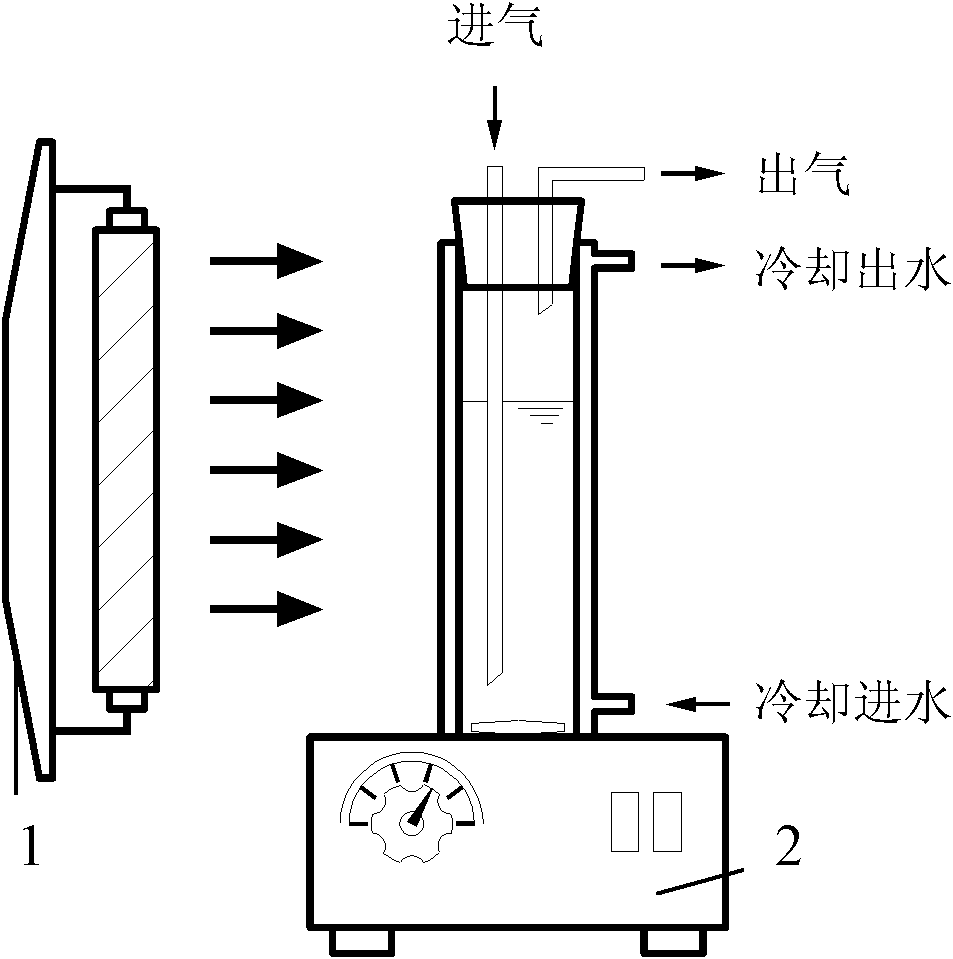

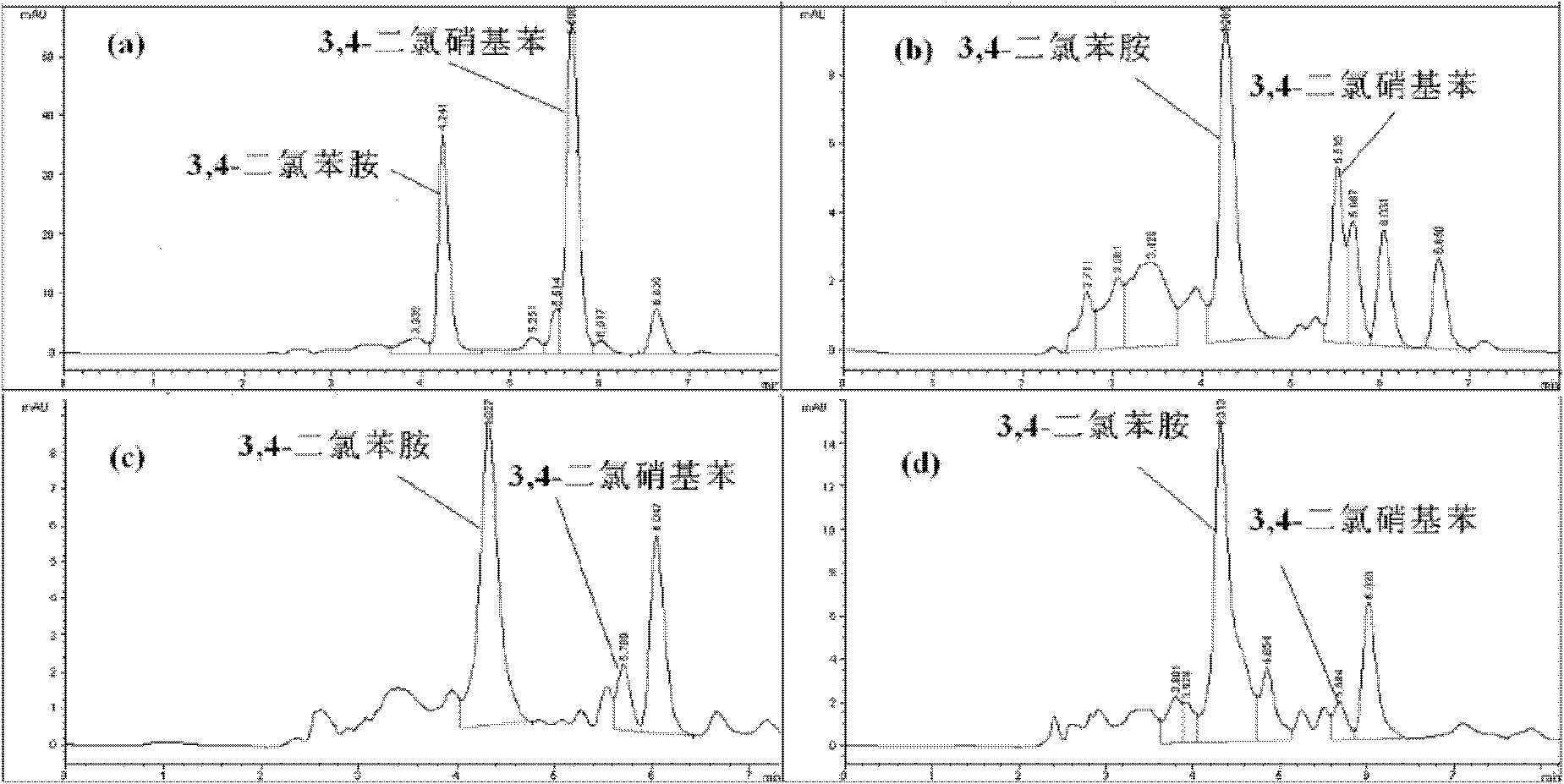

[0027] Example 1 Weigh 0.5g of 3,4-dichloronitrobenzene, 0.3g of solid powdery porous TiO with an average particle diameter of 10-15nm 2 Catalyst and 0.25g surfactant subwet159, put it into a photocatalytic reactor with a magnetic rotor, add 50mL of anhydrous methanol solution, that is, the concentration of 3,4-dichloronitrobenzene is 10g / L, the concentration of the catalyst The concentration is 6g / L, the concentration of the surfactant subwet159 is 5g / L, start the magnetic stirrer 2, in an inert gas nitrogen atmosphere, under the stirring of the magnetic stirrer 2, first perform dark adsorption for 10min, and then turn on 250W , radiation intensity 4120μW / cm 2 UV lamp, after irradiating for 20h, the reaction is terminated, and the solid powdery TiO is filtered out. 2 Catalyst, the resulting filtrate was analyzed by Aglient1100 high performance liquid chromatography (HPLC), and the yield of 3,4-dichloroaniline was 71.30%. The total time of the whole reaction ultraviolet lamp...

Embodiment 2

[0028] In Example 2, except that isopropanol was used instead of anhydrous methanol as a solvent, other reaction conditions were the same as in Example 1. As a result, the yield of 3,4-dichloroaniline was 34.20%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com