Inductive probe for inducing array structure of coils

An array structure and induction probe technology, applied in the field of induction probes, can solve the problem of undiscovered induction coil arrays, etc., and achieve the effects of high strength, easy sliding debugging, and low specific gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

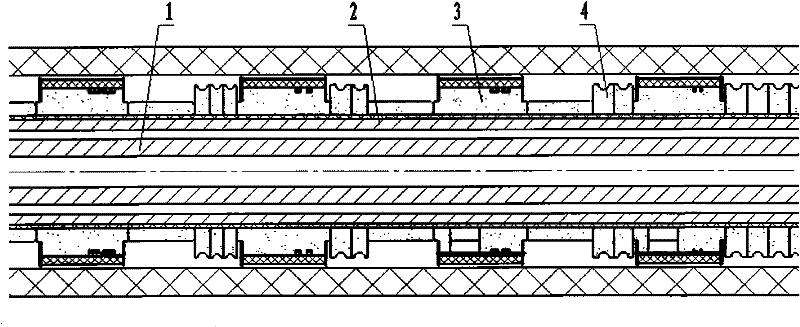

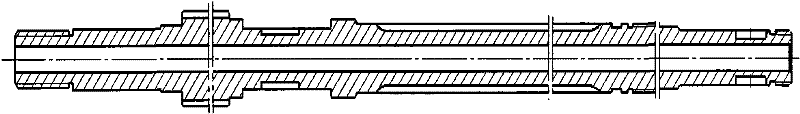

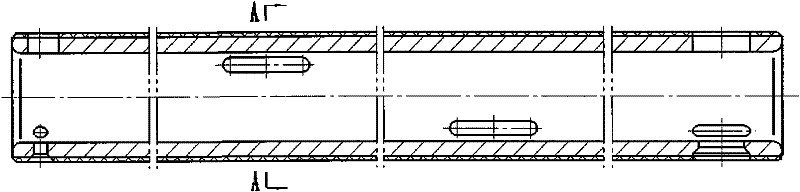

[0024] The structure of the present invention will be described below in conjunction with the accompanying drawings.

[0025] It is composed of a metal mandrel 1, a composite copper tube 2, a coil skeleton 3, and a spacing adjustment member 4; the metal mandrel is a hollow structure, and the wall of the metal mandrel perpendicular to the axis is provided with a threading hole through the inside and outside. The outer round wall of the mandrel rod is provided with a coil skeleton wire slot and an oil slot; the composite copper tube is sheathed outside the metal mandrel, and the outer round wall of the composite copper tube is provided with a coil skeleton sliding slot; the coil skeleton is provided with a threading hole and Winding groove, the coil is wound on the winding groove, the coil frame is arranged in an array, and installed on the sliding groove of the coil frame of the composite copper tube. The coil frame is composed of a transmitting coil and eight sets of receiving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com