Film-type wall water pipe boiler inspection door structure

A water-tube boiler and membrane wall technology is applied to the door, combustion method, combustion chamber and other directions of the combustion chamber, which can solve the problems of cumbersome work, easy scalding, poor heat insulation effect, etc., to overcome the single function and good heat preservation effect. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

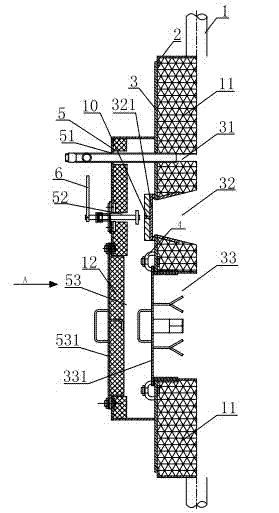

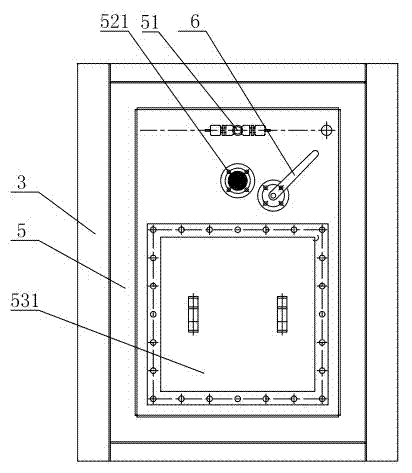

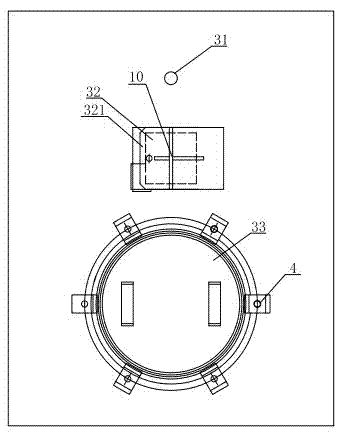

[0015] Such as Figure 1~4 As shown, the installation structure of the membrane wall water tube boiler inspection door includes the embedded part 2 fixedly arranged on the membrane wall 1 around the inspection port, the embedded part 2 is welded with the door seat plate 3, the membrane wall 1 and Refractory mud 11 is provided in the gap of the door seat plate 3. The door seat plate 3 is provided with an inner test port 31, an inner fire port 32, and an inner manhole 33. The diameter of the inner manhole 33 should meet the requirements of personnel access for maintenance The needs of the mouth; the inner view flame port 32 is provided with an inner view flame port cover plate 321, the inner view flame port cover plate 321 is welded with a cross-shaped flat iron 10 to reduce its deformation after heating, the inner view flame port cover plate 321 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com