Fully distributed optical fiber strain and vibration sensing method and sensor

A vibration sensor and optical fiber strain technology, which is applied in the direction of converting sensor output, processing polarization reflectometer, testing optical fiber/optical waveguide equipment, etc., can solve difficult strain detection and other problems, achieve low overall cost, improve measurement function and application range , to reduce the effect of false positives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

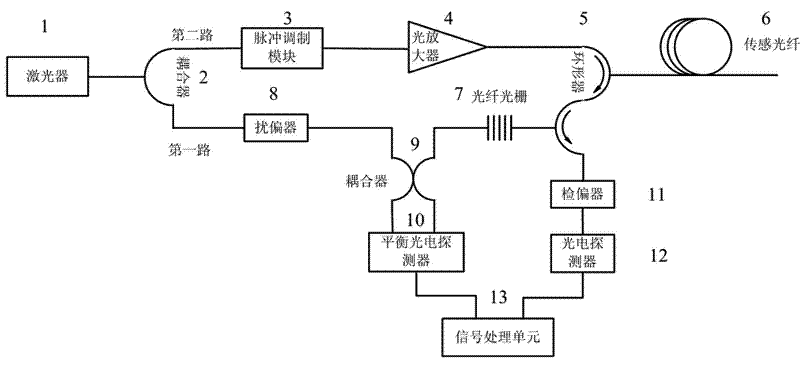

[0024] A fully distributed strain and vibration sensor structure such as figure 1 , the specific implementation steps of measuring strain and vibration are as follows:

[0025] 1) The continuous light output by the laser (1) is divided into two paths after passing through the first coupler (2);

[0026] 2) One of them is used as a reference light, which is connected to the first input end of the second coupler (9) after passing through the polarizer (8);

[0027] 3) The second path is modulated into pulsed light by the pulse modulation module (3), and then injected into the sensing fiber (6) as detection pulsed light through the circulator (5) after passing through the optical amplifier (4).

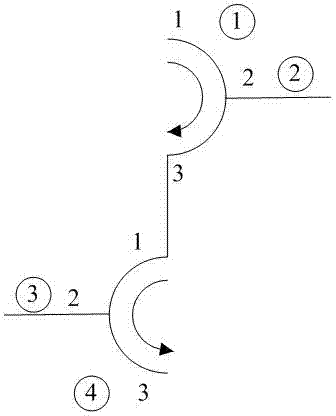

[0028] 4) The Rayleigh scattered light and Brillouin scattered light in the sensing fiber (6) are returned and emitted from the third port of the circulator (5).

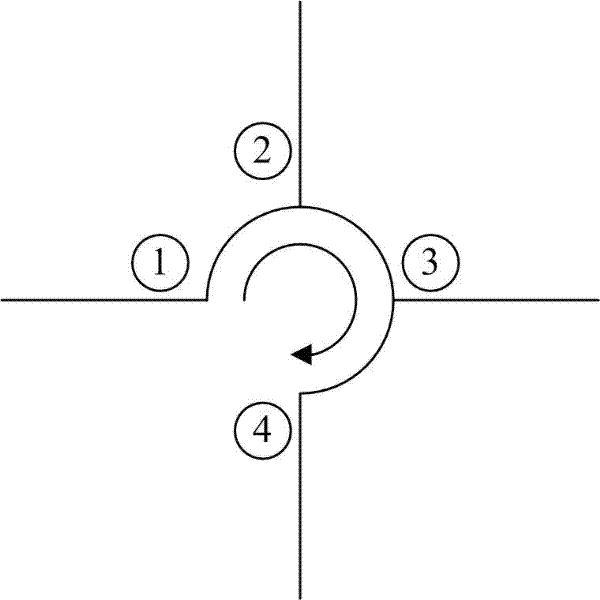

[0029] 5) The fiber grating (7) transmits the Brillouin scattered light and reflects the Rayleigh scattered light....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com