Terahertz wave polarization conversion and unidirectional transmission device with double-layer dielectric-metal grating structure

A metal grating and polarization conversion technology, applied in the field of terahertz applications, can solve the problems of polarization conversion rate, isolation, insertion loss working bandwidth that cannot meet the application system, low forward transmission transmittance, affecting device practicability, etc. Achieve the effect of overcoming the shortcomings of single function, low material cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The terahertz wave polarization conversion and unidirectional transmission device with a double-layer dielectric-metal grating structure involved in the present invention will be described in detail below with reference to the accompanying drawings.

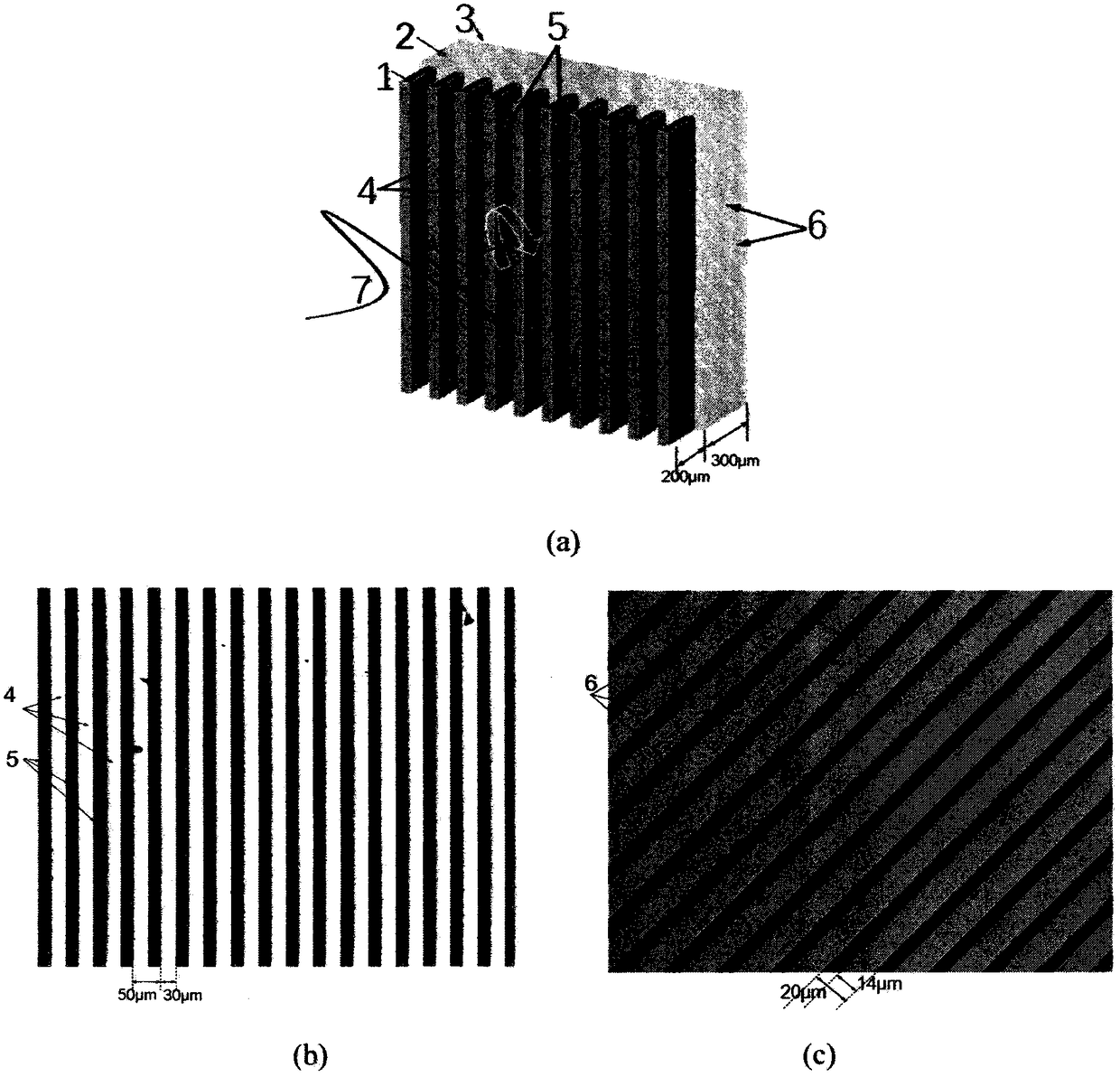

[0025] figure 1 It is a structural schematic diagram of a terahertz wave polarization conversion and unidirectional transmission device with a double-layer dielectric-metal grating structure in an embodiment of the present invention, and the structure is as follows. A dielectric grating layer with a period of 50 μm, a gate ridge width of 30 μm, and a gate groove depth of 200 μm is etched on one side of a high-resistance silicon wafer with a thickness of 500 μm. The resistivity of the high-resistance silicon is greater than 10KΩ·cm. A metal grating layer with a period of 20 μm and a metal grid strip width of 14 μm is plated on the other side of the substrate, the metal material is gold, and the thickness of the gold layer is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com