Improved setting tool structure of coil cover creep distance

A technology of creepage distance and coil wire, which is applied in the field of motors, can solve the problems of difficult to guarantee the quality of the stator, low shaping efficiency, and difficult to guarantee the creepage distance, etc., and achieve the effect of simple structure, high efficiency and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

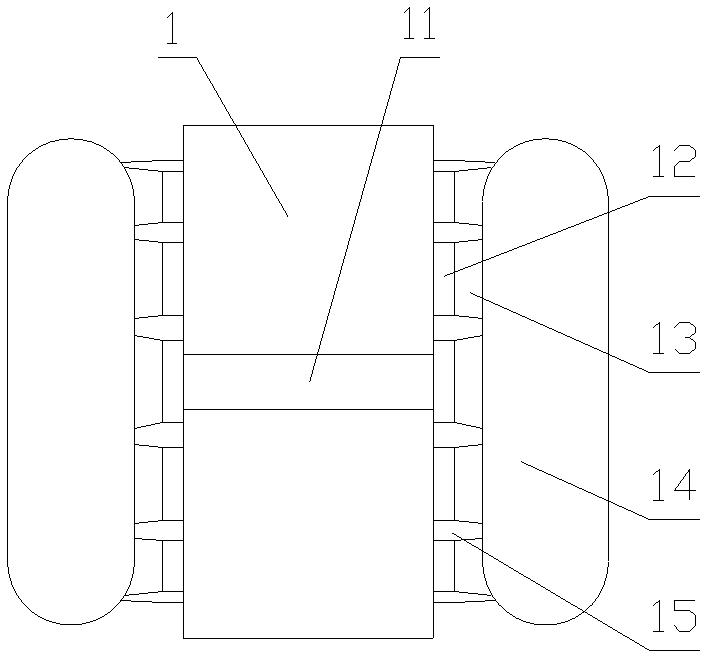

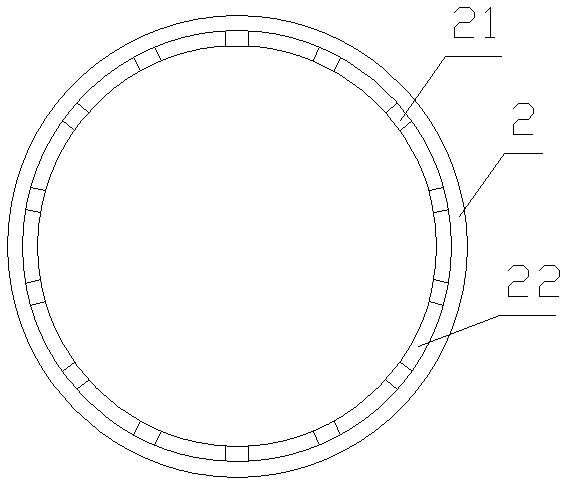

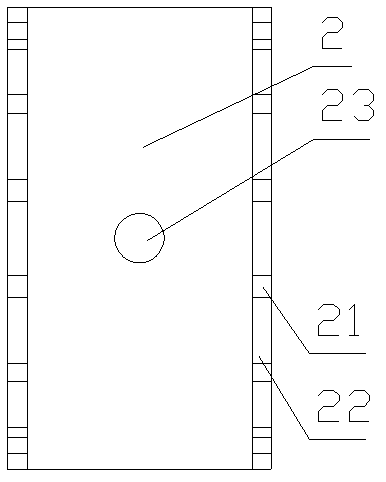

[0021] like Figure 1 to Figure 9 As shown, it is an embodiment of the stereotyped tooling for the creepage distance of the coil wire package of the present invention. The shaped tooling includes a hollow cylindrical mold body 2 set on the outer side wall of the stator 1, and the side walls at both ends of the mold body are in the Several slots 21 are evenly opened in the circumferential direction, and the positions of the slots correspond to the positions of the gaps 15 between the coil slots 12 on the stator. The positioning pieces 3 are inserted in the slots, and the thickness of the positioning pieces is equal to the creepage The setting tool also includes several telescopic claws 6 corresponding to the positioning pieces one by one, and the telescopic claws control clamping or loosening of the positioning piece and control the positioning piece to insert or leave the slot. The shaping tool also includes a gland 4, the gland is in the shape of a barrel, the gland is sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com