Environmentally friendly gas cabinet isolating switch spindle

A technology of isolating switch and gas cabinet, which is applied in the field of main shaft of isolating switch of environment-friendly gas cabinet, which can solve the problems of assembly trouble, many parts, asynchronous action, etc., and achieve the effect of increasing creepage distance, simple assembly and few parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

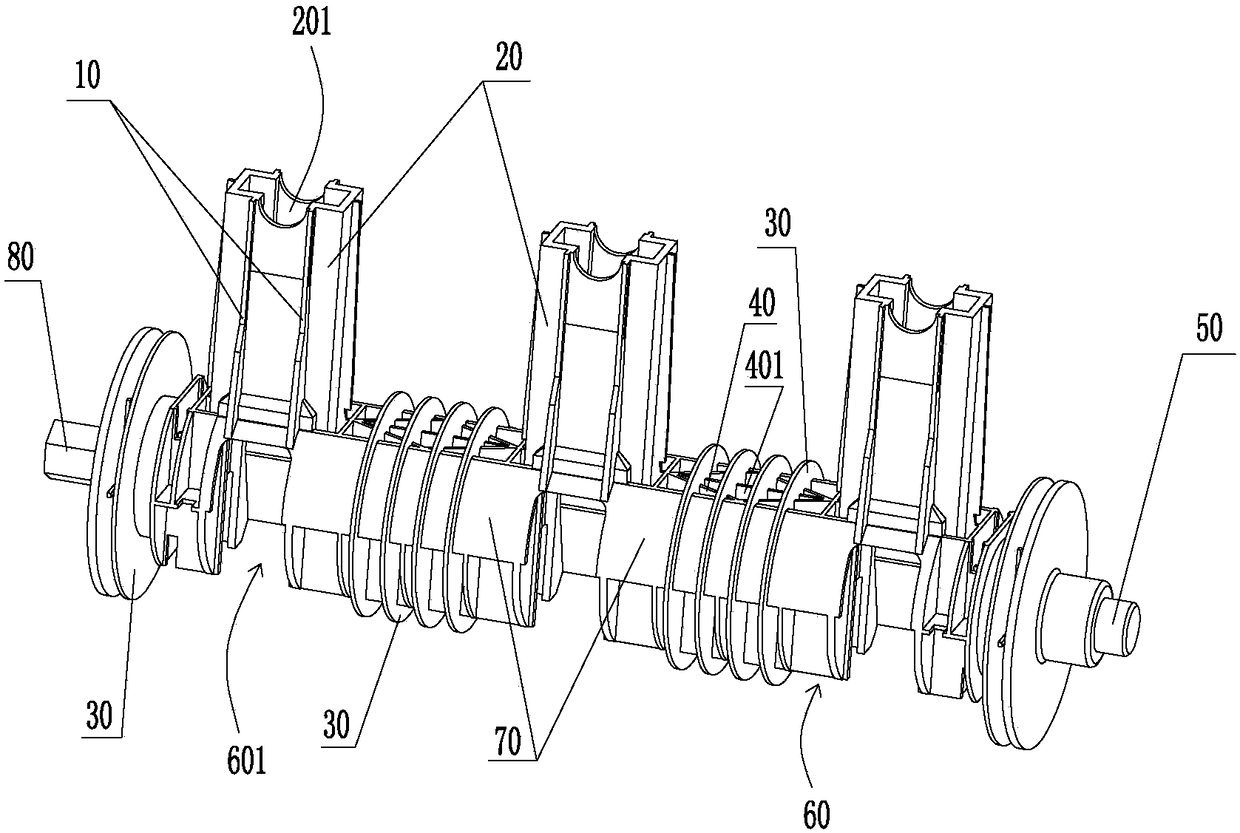

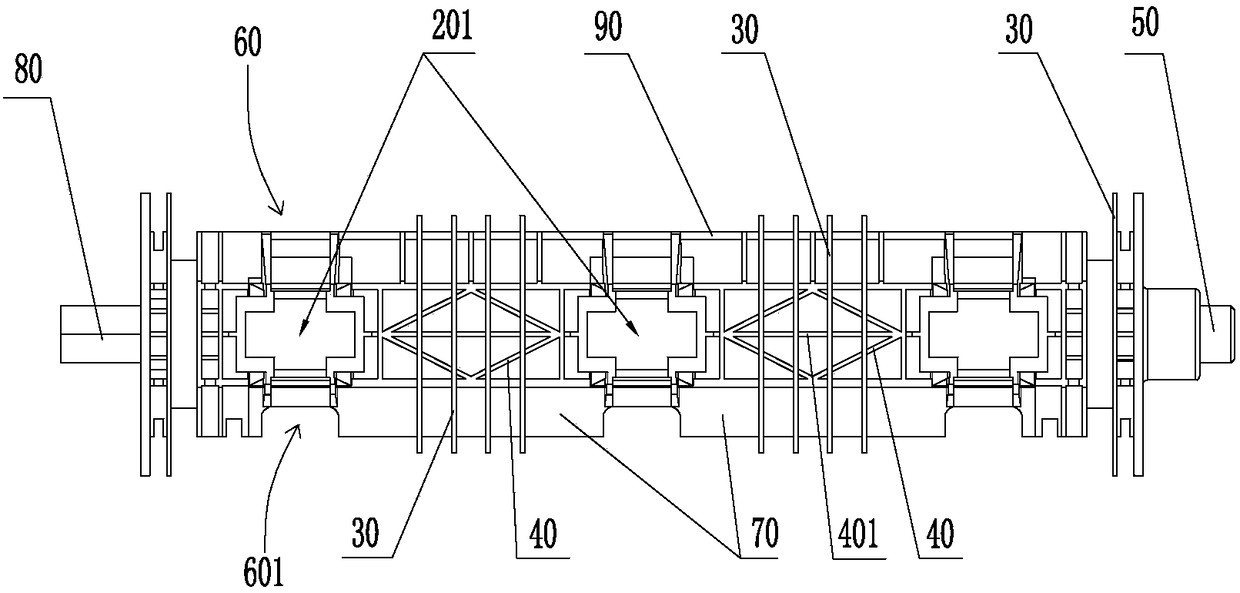

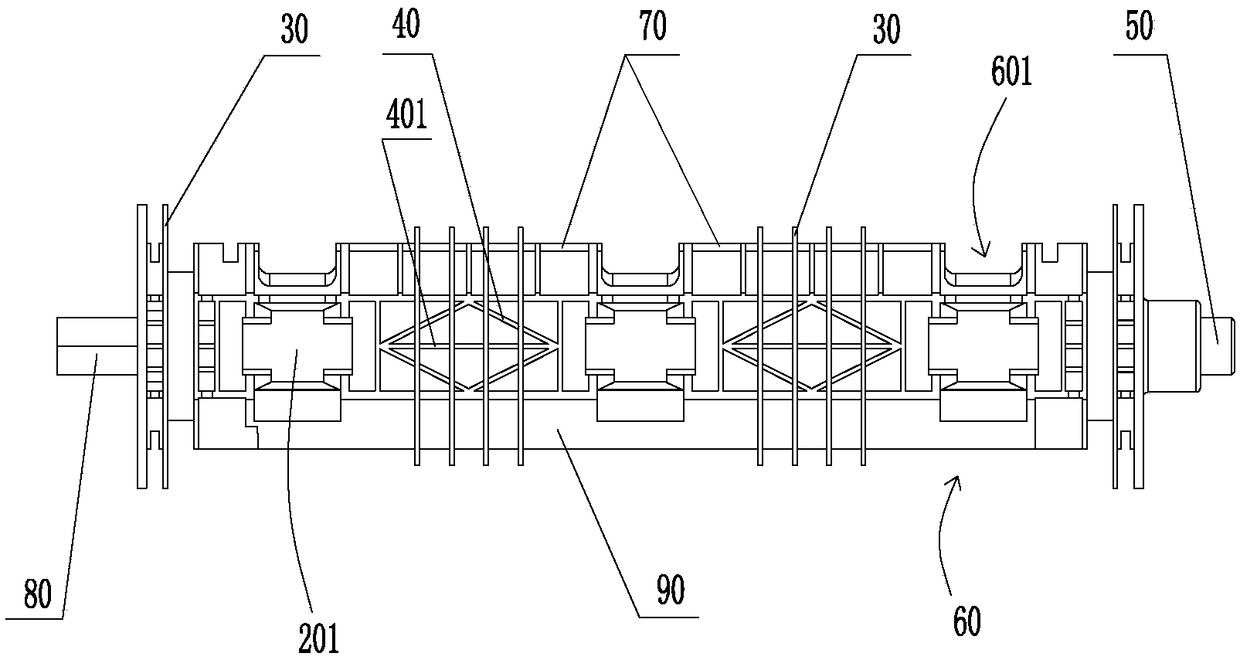

[0024] The main shaft of the environmental-friendly gas cabinet isolating switch of the present invention will be further described in detail in conjunction with the accompanying drawings and specific implementation methods:

[0025] Such as Figure 1 to Figure 4 As shown, in this specific embodiment, the main shaft of an environment-friendly gas cabinet isolating switch of the present invention includes a base 60, on which three bosses 20 are arranged at equal intervals, and each boss 20 is perpendicular to the base 60, The boss 20 is hollow to form a slideway 201. Three notches 601 are provided on the front side wall of the base 60 at the bottom of the three bosses 20. The three notches 601 communicate with the three slideways 201 respectively. There are several circular pieces 30 coaxial with the base 60, at least four circular pieces 30 between adjacent bosses 20, at least one circular piece 30 at both ends of the base 60, and adjacent bosses 20. A front arc-shaped plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com