Stator for electric motors and permanent magnet rotating machines

A motor and stator technology, applied in the field of permanent magnet rotating electrical machines, can solve the problems of reduced insulation distance, difficulty in ensuring insulation performance, and high requirements for high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

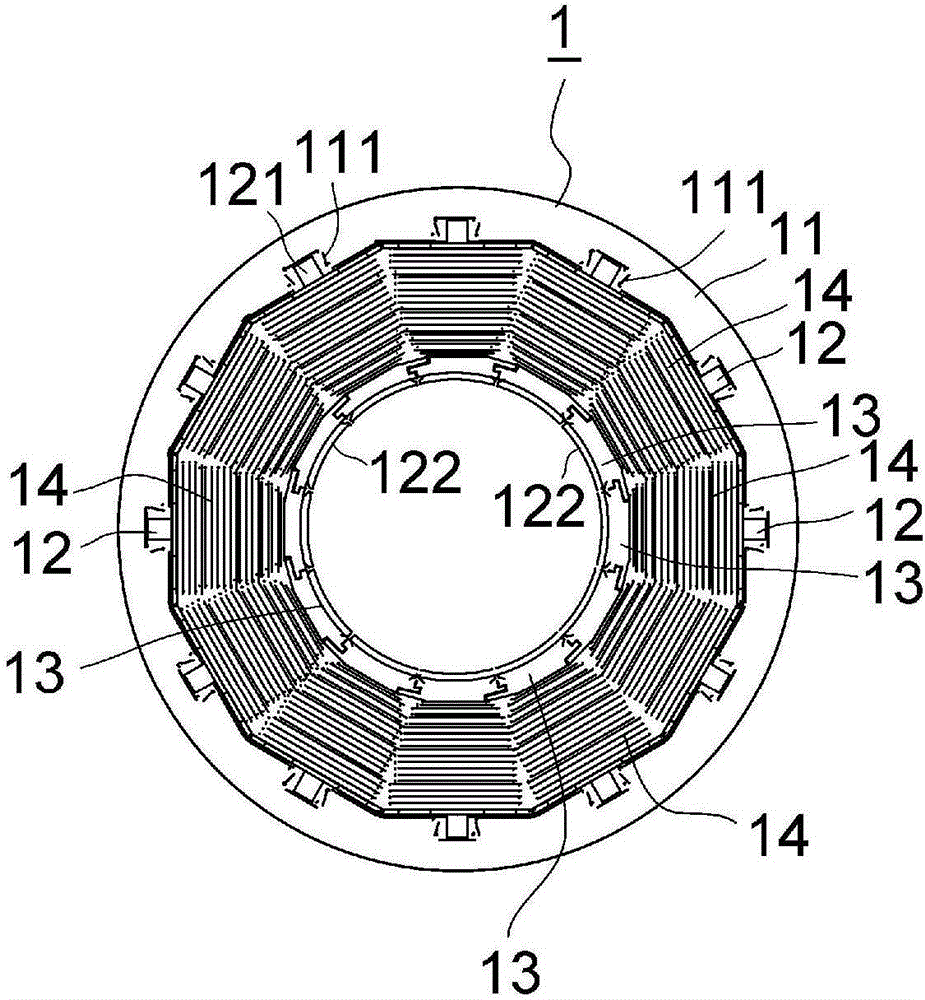

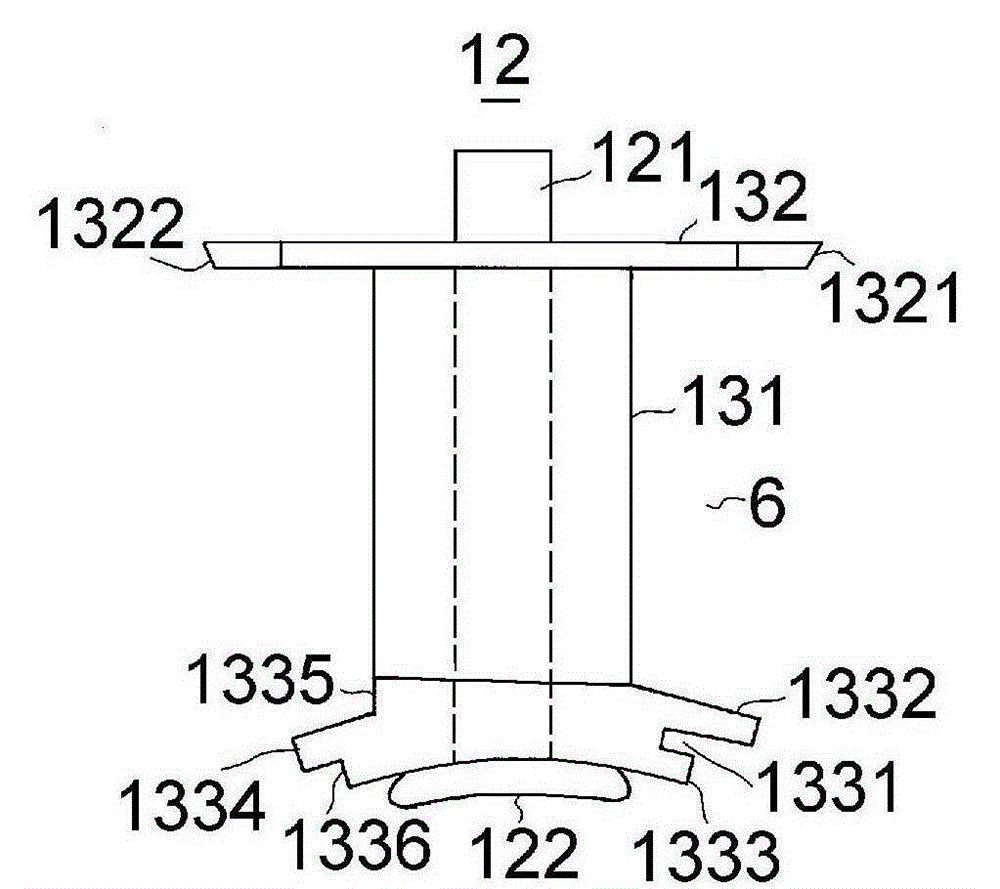

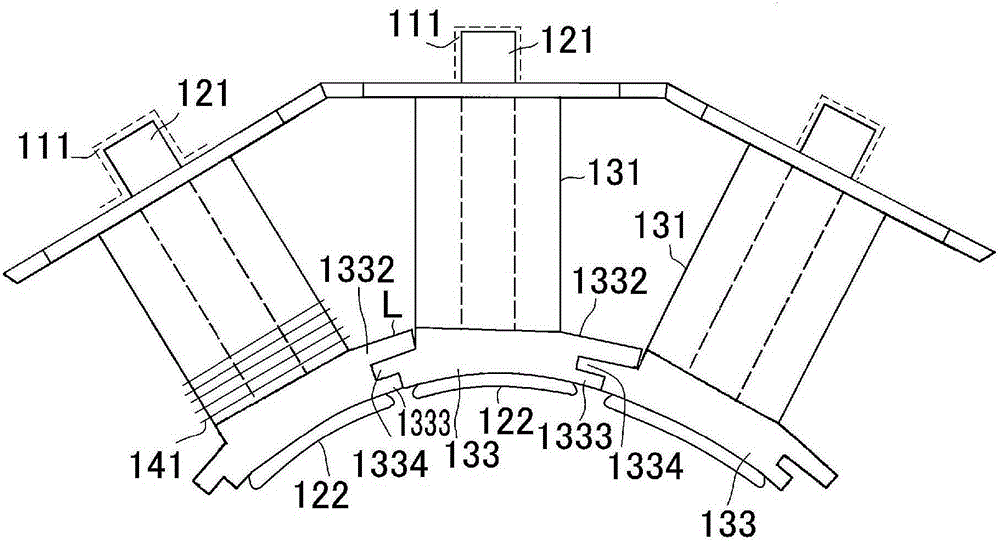

[0057] figure 1 It is a structural diagram showing the stator structure of the main components included in the stator of the motor of the present invention, figure 2 will be figure 1 A part of the coil bobbin (single body) is enlarged to show the structural diagram of the structure of the coil bobbin, image 3 It is a configuration diagram illustrating the combination of adjacent bobbins by combining a plurality of bobbins, Figure 4 with Figure 5 It is an exploded perspective view showing main parts and assembly structures of a yoke core, a tooth core, and a bobbin of the stator of the present invention.

[0058] In these figures, 1 denotes a stator (stator) that interacts with the rotor (not shown) of the motor to generate rotational momentum. The stator includes a cylindrical yoke core (yoke core) 11 and a yoke core provided on the yoke core. Parts described later inside the cylinder. The stator also includes a plurality of T-shaped tooth cores 12 made of split iron ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com