Strain engineered composite semiconductor substrates and methods of forming same

A composite substrate and semiconductor technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as degradation and difficult film growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

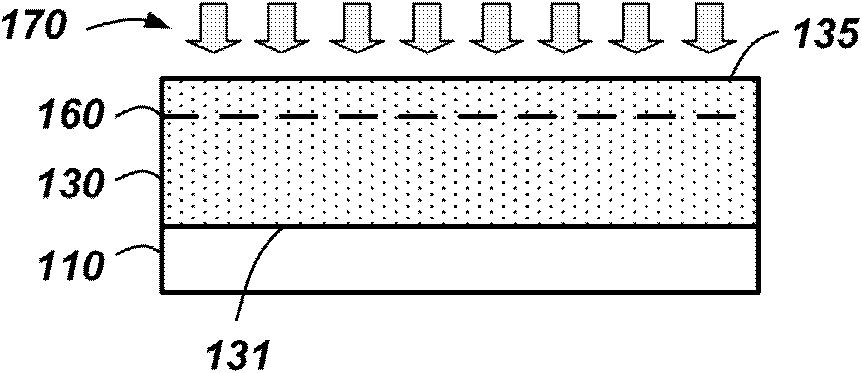

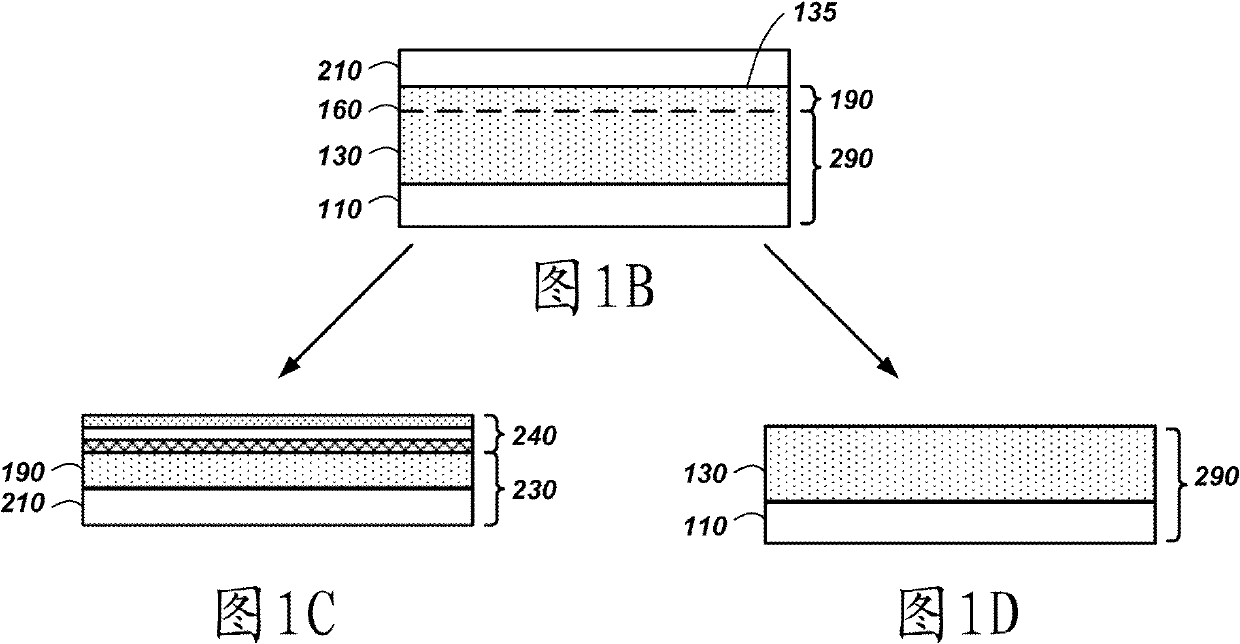

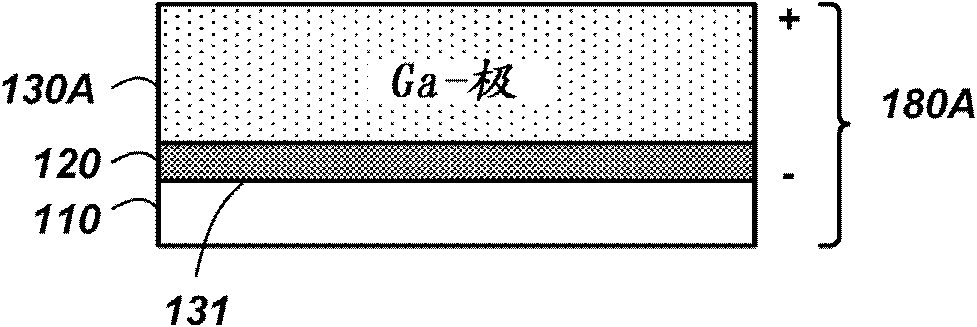

[0094] As a first example, an InGaN (or GaN) donor structure is formed. The example basically follows the Figure 3A-3G Actions and structures shown in . In this example, a sapphire growth substrate 110 was used. ZnO is deposited as a buffer layer 120 on the sapphire growth substrate 110 by means of, for example, MOVPE, HVPE or MBE.

[0095] On the surface of the ZnO buffer layer 120, lattice-matched In 0.18 Ga 0.82 N or strained GaN. The thickness of the nitride material can be kept below a critical thickness to prevent defect formation in the case of strained Ill-nitride material growth.

[0096] Use SiO 2 A sapphire carrier substrate 150 is bonded as a bonding layer to the surface of the strained Ill-nitride material 130 opposite the sapphire growth substrate 110 . Bonded structures can be strengthened by means of thermal annealing and / or using plasma activation as a pre-bonding surface treatment.

[0097] The back surface of the buffer layer 120 can be exposed by r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap