Method for welding heavy-duty trough-type steel

A welding method and channel-shaped steel technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of waste products, increased flame correction costs, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

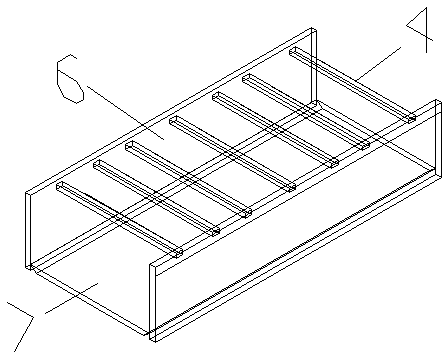

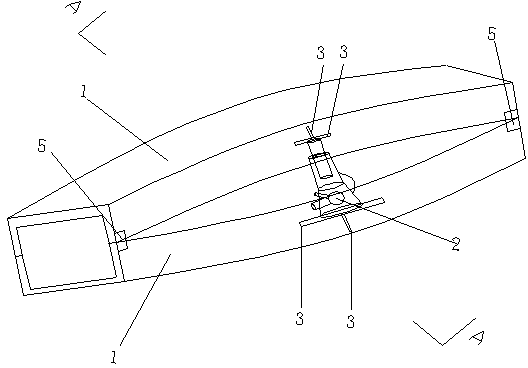

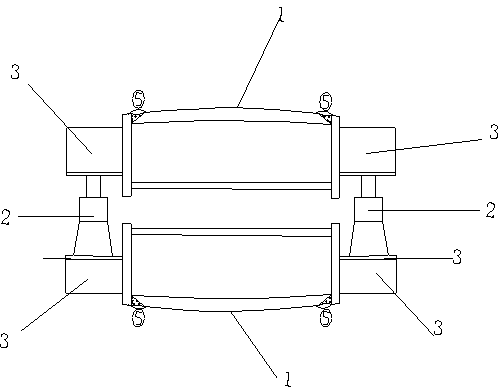

[0013] See attached figure 1 , 2 , 3 shown.

[0014] In order to prevent angular deformation, the specific welding sequence is as follows: ①Adopt rigid fixing method; fix the supports (4) in the groove respectively on the inner side of the shaped steel wing plate (6). The purpose is to prevent the inner and outer corner deformation that may be produced by the steel during the welding process.

[0015] Carry out root welding: The welding method adopts carbon dioxide gas shielded welding that produces the least welding deformation.

[0016] Perform cover welding: In order to improve the appearance quality of the weld, double wire submerged arc welding is selected for cover welding. Due to the large amount of submerged arc welding welding deformation, the weld seam shrinks longitudinally during the welding process, resulting in deflection deformation of the component. In order to prevent the occurrence of flexural deformation, the anti-deformation method was chosen. The spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com