Correcting method of boron and phosphorus content measurement in BPSG

A calibration method and phosphorus content technology, applied to measuring devices, instruments, scientific instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

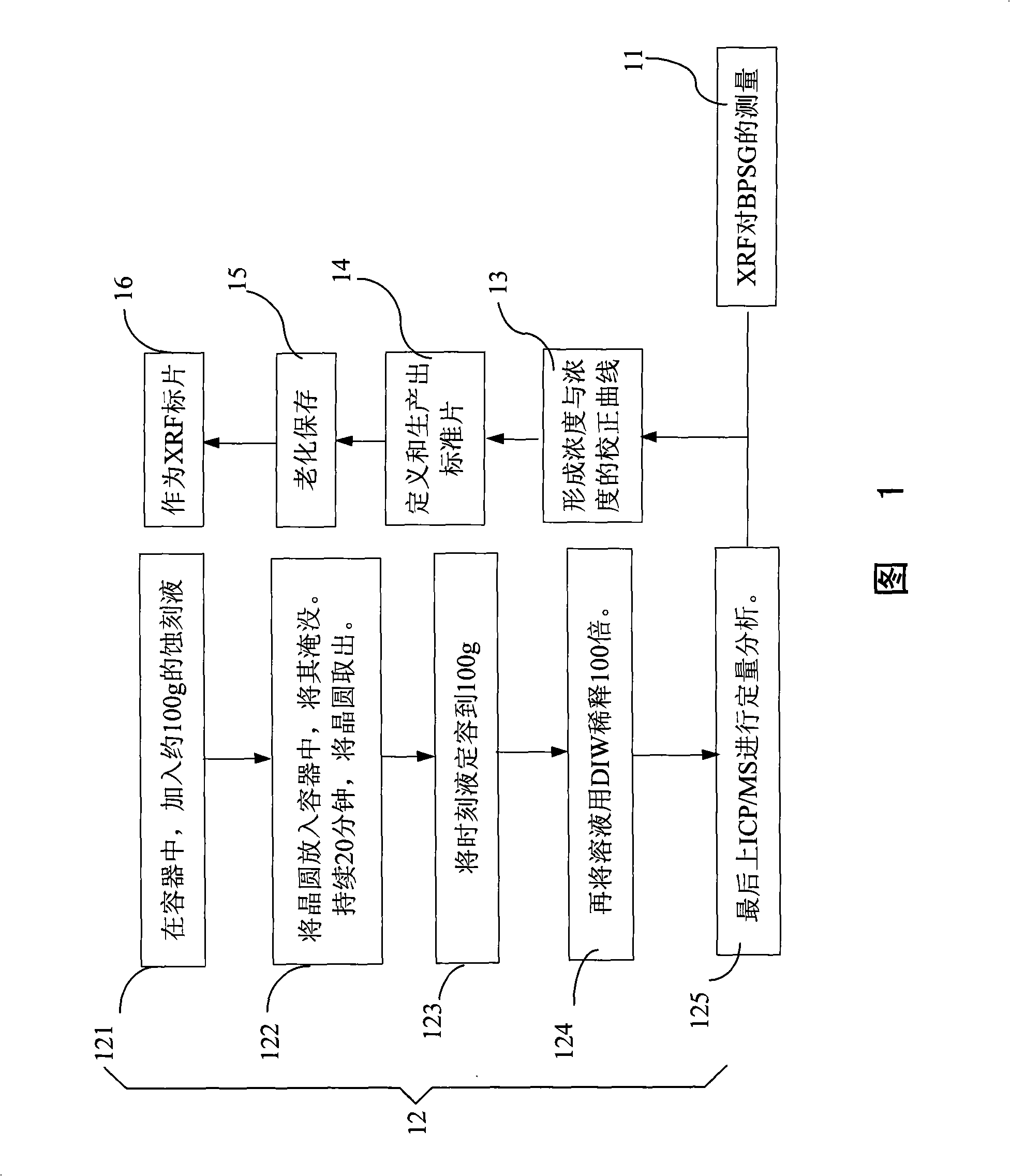

[0012] Referring to Fig. 1, the steps of an embodiment of the present invention are as follows:

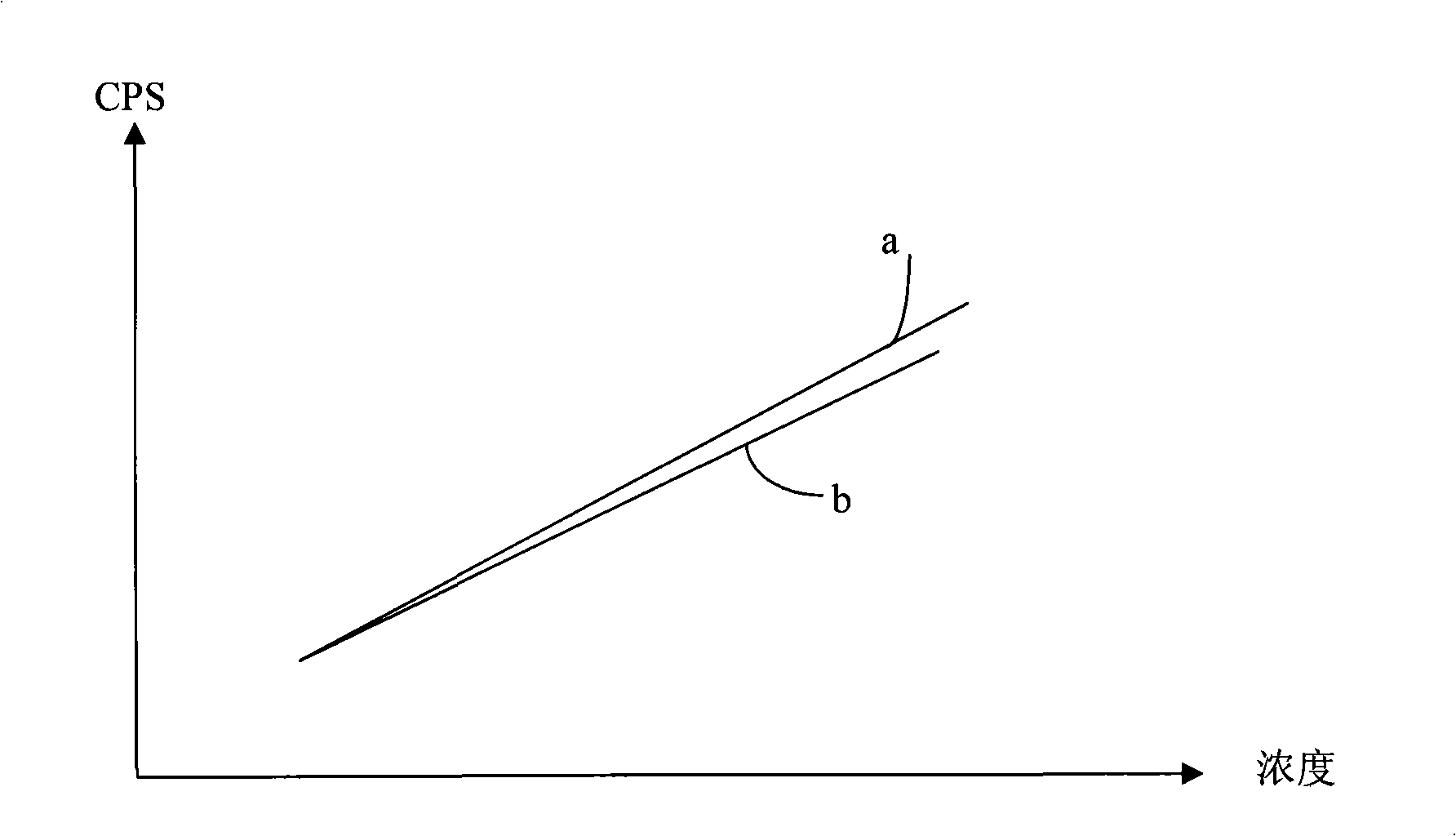

[0013] First is step 11, using X-ray fluorescence (XRF) to measure the boron and phosphorus concentrations of a series of borophosphosilicate glass (BPSG) films, XRF reflects the measured concentrations with signal intensity, and according to the XRF baseline, obtain And record the boron and phosphorus concentrations of each BPSG thin film corresponding to the signal intensity.

[0014] Next is step 12, using wet chemical method to measure the boron and phosphorus concentration of the BPSG film, that is, dissolving the BPSG film in a specific etching solution, and measuring the boron and phosphorus concentration with elemental quantitative analysis equipment.

[0015] It is better to use ICP / MS (Inductively Coupled PlasmaMass Spectrometer, Inductively Coupled Plasma Mass Spectrometer) for elemental quantitative analysis equipment. Before using this equipment, it needs to undergo a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com