Novel terracotta extruding machine

A technology of extruder and terracotta plate, which is applied in the field of new terracotta plate anti-extrusion machine, can solve the problems of affecting output, difficulty in achieving multi-purpose of one machine, high cost, etc., to improve performance and service life, facilitate installation and maintenance, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

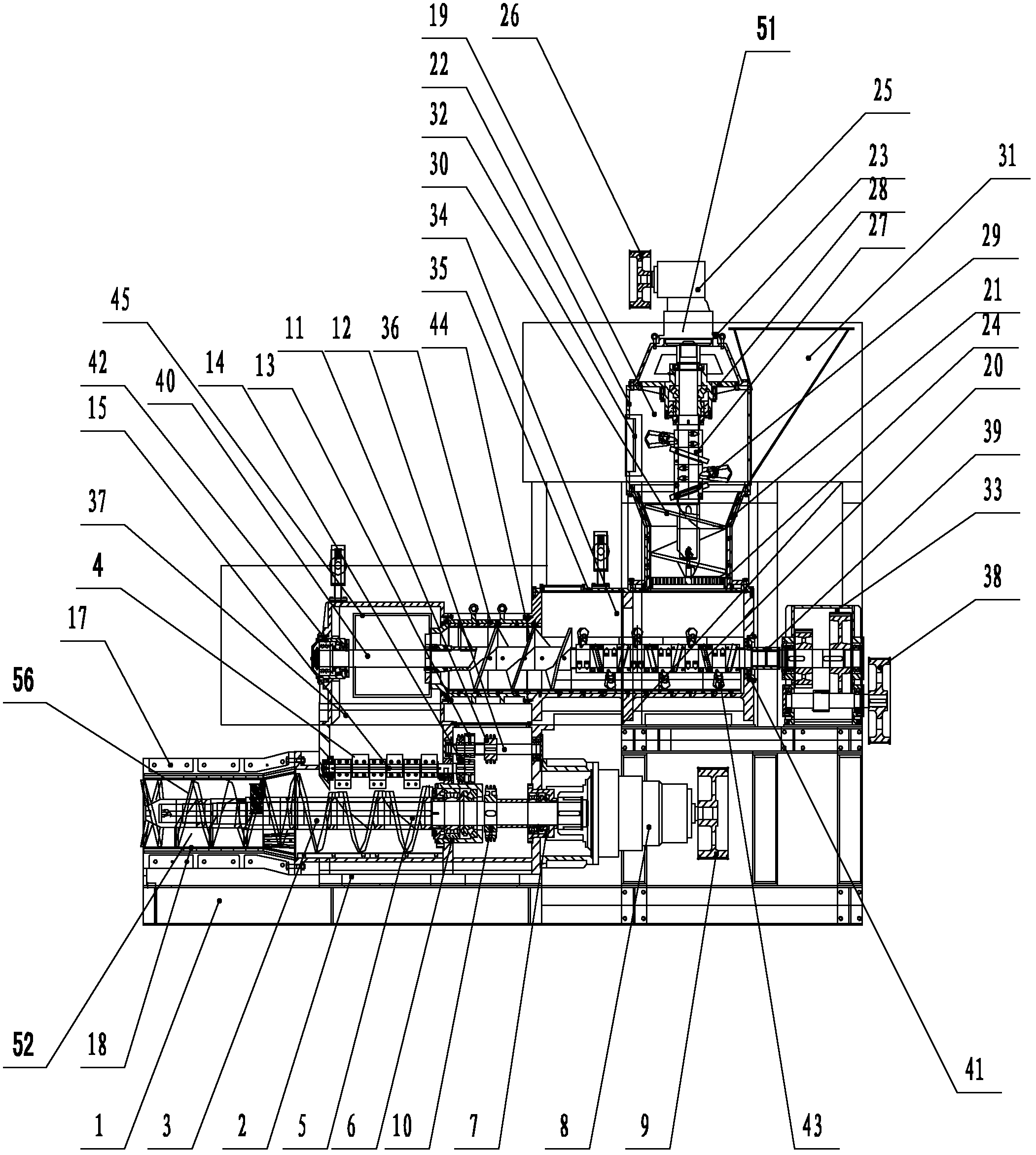

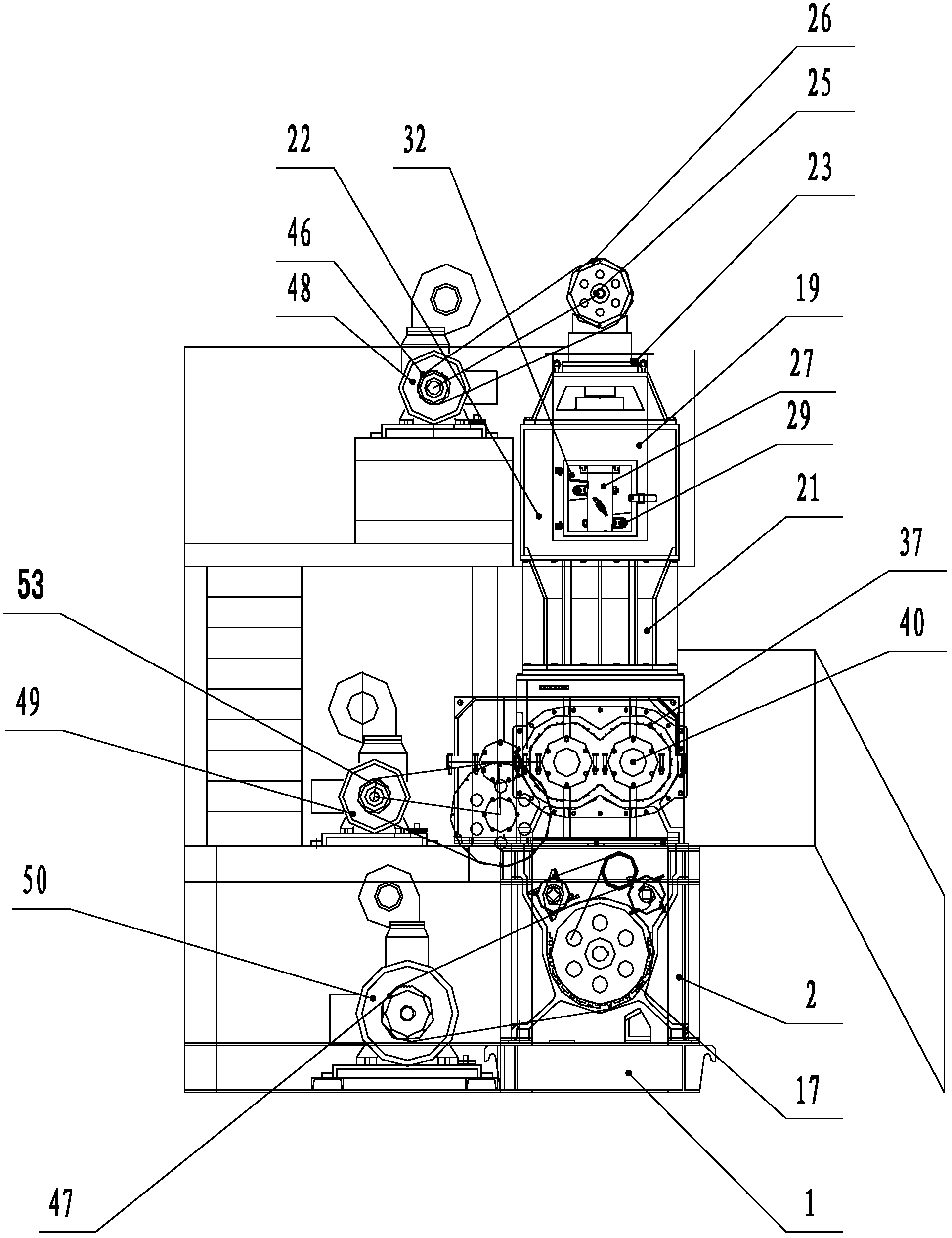

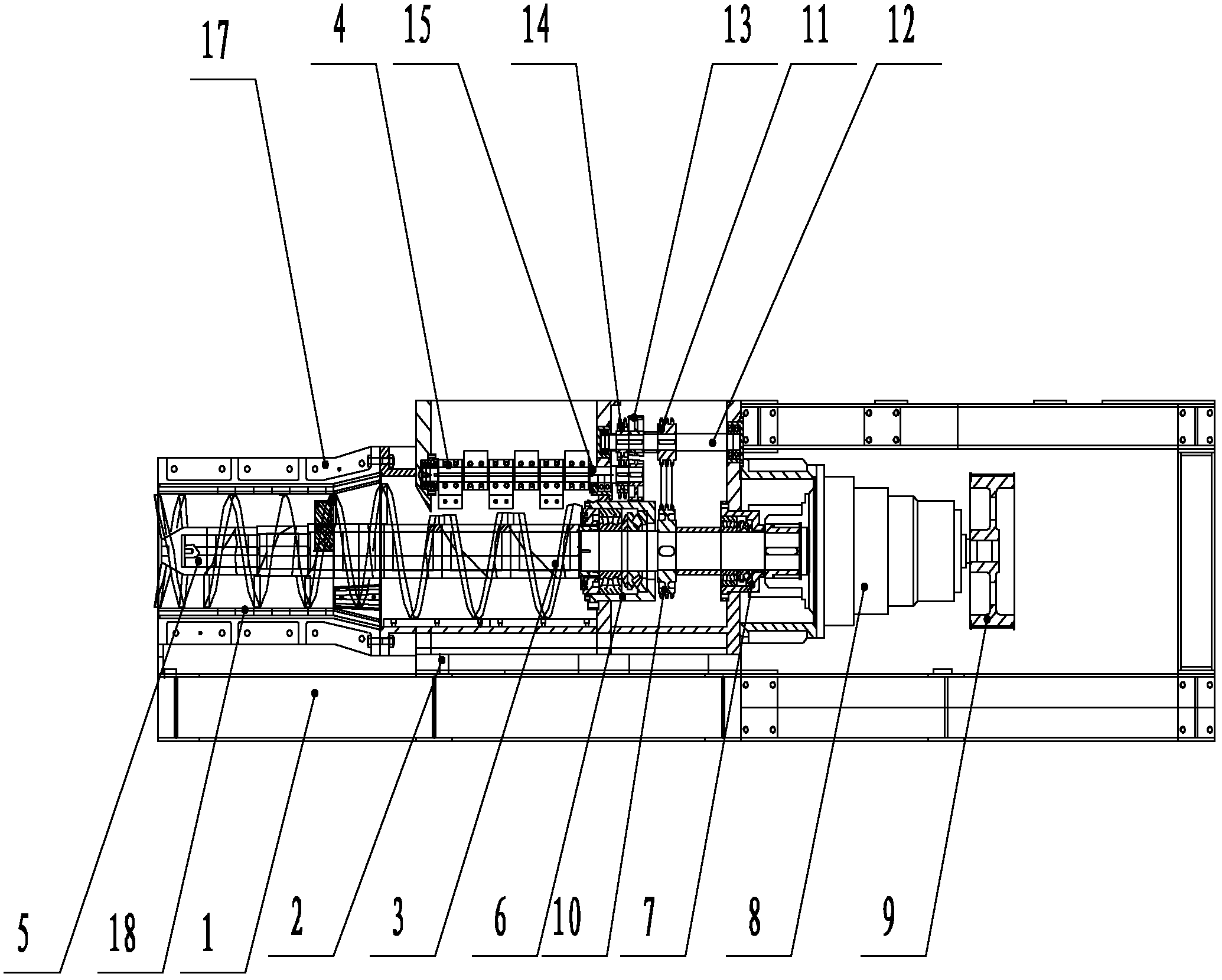

[0023] Attached below figure 1 , 2 , 3, 4, 5, 6, 7 describe an embodiment of the present invention.

[0024] The novel ceramic plate extruder comprises a base 1, a bed 2 is provided on the base 1, and a motor I 48, a motor II 49 and a motor III 50 are arranged on the fuselage 2 sequentially from above, and the bed 1 is provided with There is an upper-level stirring device 51 and a lower-level extrusion device 52. The upper-level stirring device 51 is composed of a vertical stirring part 19 and a horizontal stirring part 20. The lower end of the vertical stirring part 19 is vertically connected to the upper end of the horizontal stirring part 20; The lower extrusion device is composed of an extrusion part 3 and a mud pressing part 4, the upper end of the mud pressing part 4 is connected to the lower end of the horizontal stirring part 20, the mud pressing part 4 is located above the extrusion part 3 and both It is arranged in the fuselage 2, and the outlet end of the extrusio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com