Inverted Y-shaped superhigh hollow pier for large-span long continuous structural bridge

A bridge herringbone-shaped, hollow pier technology, applied in the direction of bridges, bridge construction, bridge parts, etc., can solve the problems of increase and increase of project cost, and achieve the effect of reducing project cost, feasible construction, and clear force transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

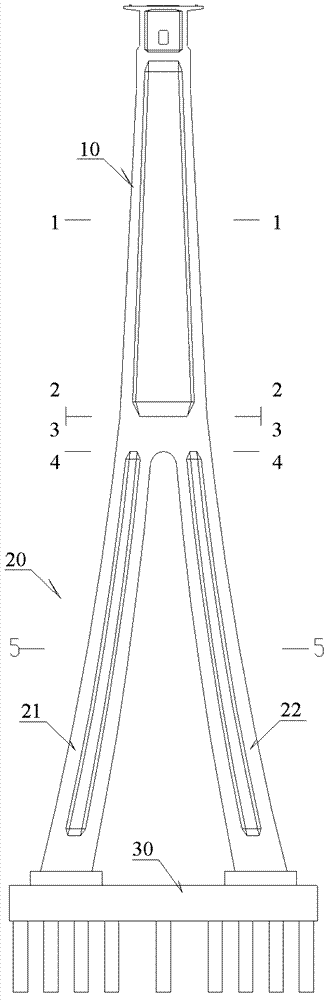

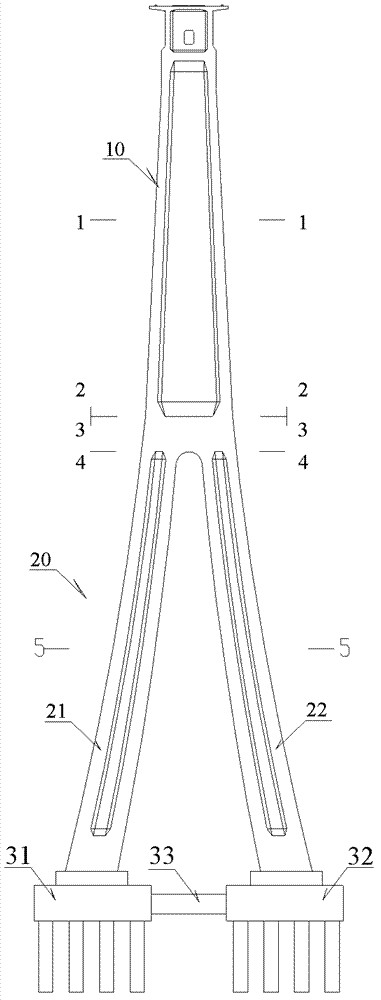

[0019] refer to figure 1 , the long-connected, long-span continuous structure bridge herringbone super-high hollow pier of the present invention includes a pier body and a cap 30 consolidated therewith. The lower section 20 of the pier is composed of two outriggers 21, 22, the top of which meets the upper section 10 of the pier to form a herringbone-shaped pier in frontal projection. The lower ends of the two supporting legs 21, 22 are respectively consolidated with the bearing platform 30; the upper section 10 of the pier body and the supporting legs 21, 22 adopt hollow sections.

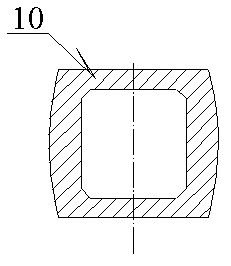

[0020] refer to image 3 , the upper section 10 adopts a rectangular hollow section with a transverse circular arc surface, which is similar to the section of a traditional hollow pier. refer to Figure 5 and Figure 6 , the legs 21, 22 adopt a transverse arc-shaped rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com