Conical friction ring transmission and method for continuously transmitting torque by means of conical friction ring transmission

A technology of friction rings and transmissions, which is applied in the direction of friction transmissions, transmissions, belts/chains/gears, etc., which can solve problems such as large structures and achieve the effect of reducing the structure volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

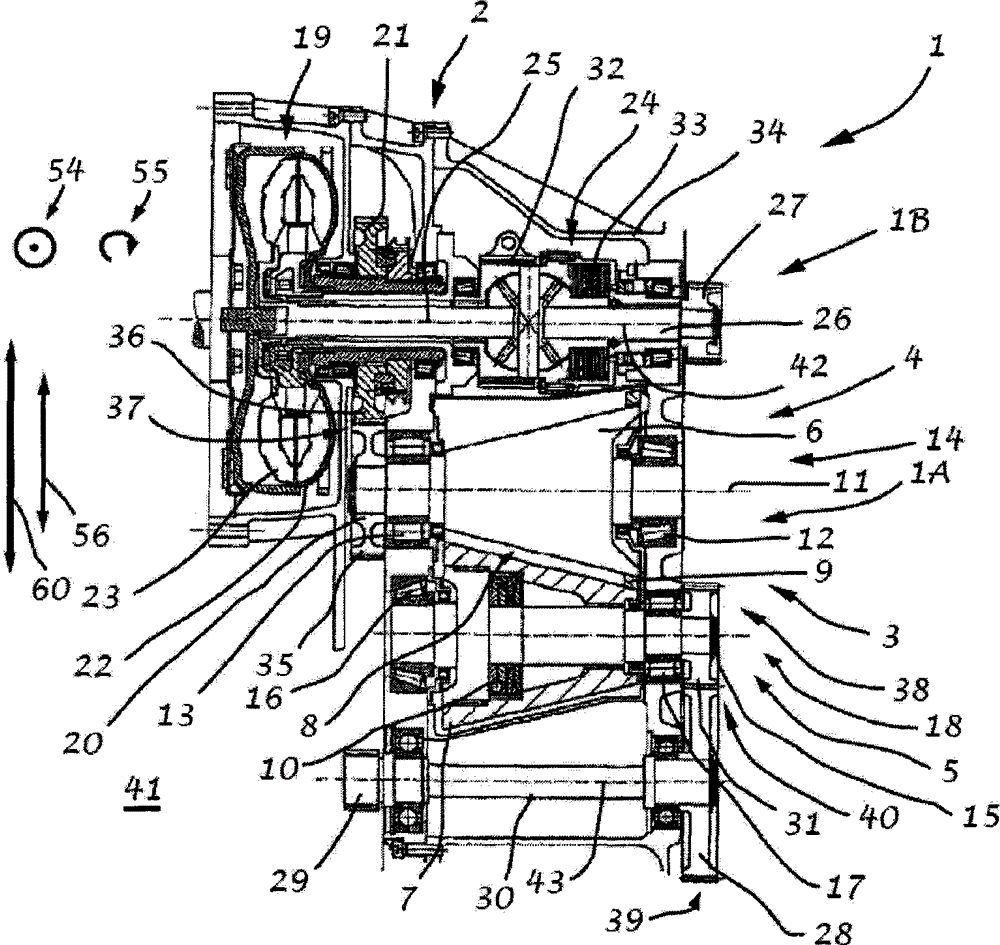

[0041] figure 1 The transmission 1 shown basically comprises two transmission stages 1A, 1B, which can be shifted selectively via a synchronized transmission 2 into a drive train. In this case, the first transmission stage 1A has a conical friction ring transmission 3 with two oppositely arranged friction cones 4 , 5 , wherein the first friction cone 4 is the input friction cone 6 of the conical friction ring transmission 3 And the second friction cone 5 is the output friction cone 7 . Two friction cones 4,5 are arranged in this way, so that friction ring 9 rings are embedded in the gap 8 of friction cone 4 running between the friction cones 4,5.

[0042] In order for the conical friction ring transmission 3 to be able to transmit particularly high torques, the friction cone 5 additionally includes in this exemplary embodiment a hold-down device 10 not described in detail here, which holds the two friction cones 4 and 5 together. The friction ring 9 is tensioned under a vari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com