Split type combined pyrometric cone

A technology of temperature measuring cone and split type, which is applied in the field of temperature measuring cone, can solve problems such as insufficient accuracy, unfavorable instrument observation, and affecting measurement effect, so as to ensure the effect of measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

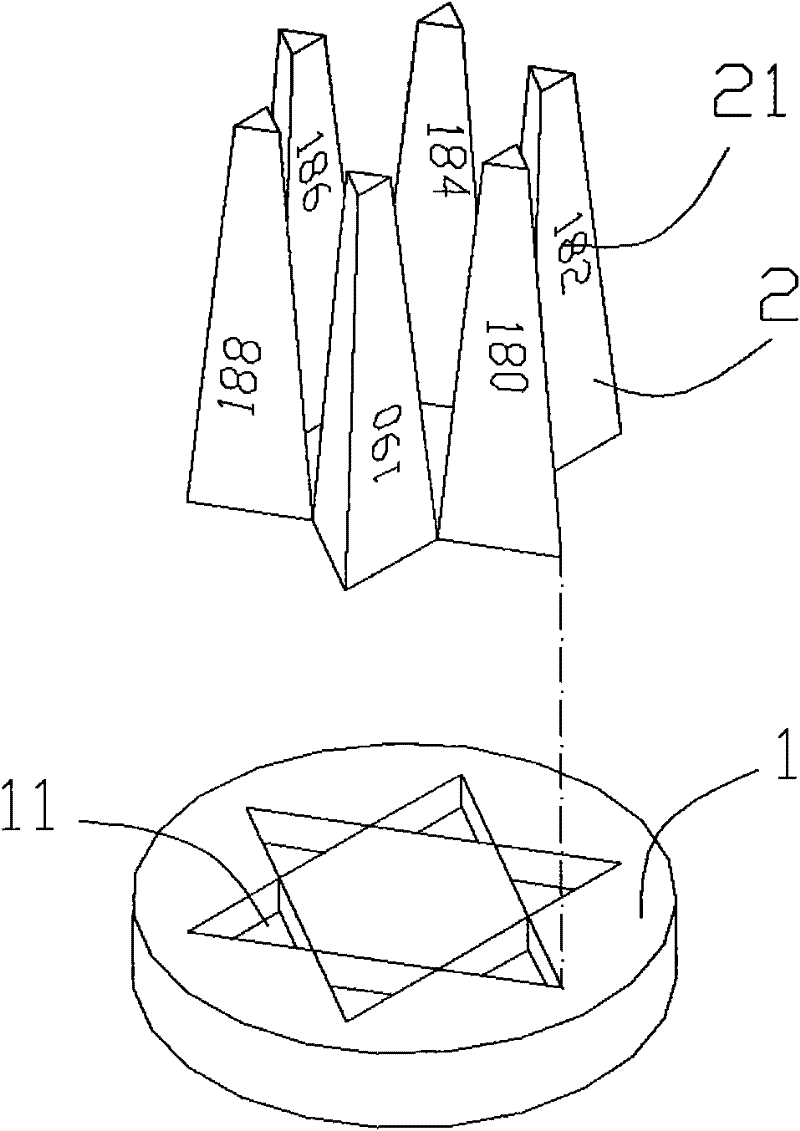

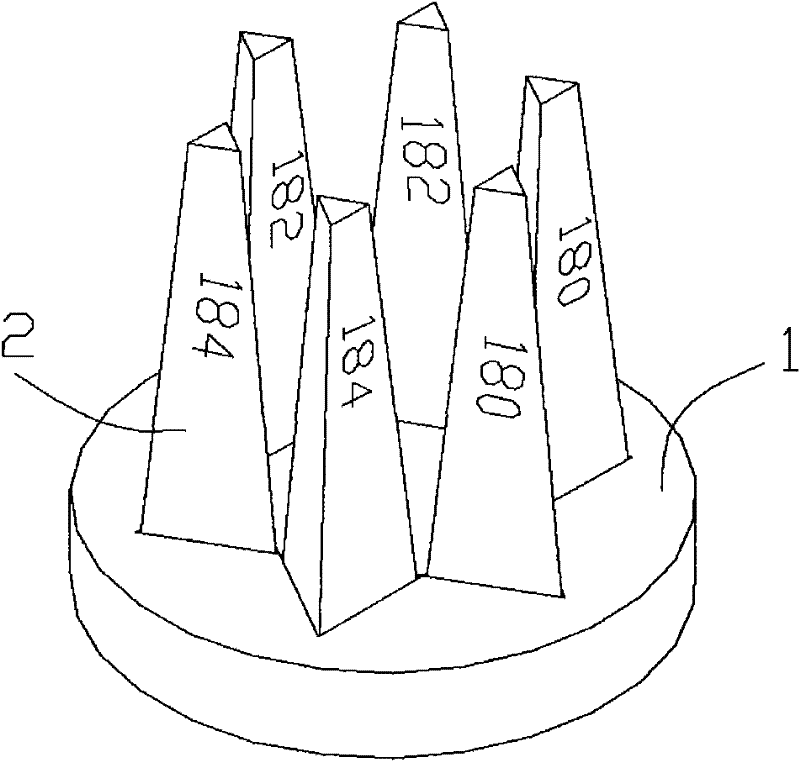

[0012] Example 1: see figure 1 As shown, the split-type combined temperature measuring cone includes a base 1 and a temperature measuring triangular cone 2. The temperature measuring triangular cone 2 is marked with a temperature-reversing model 21, and the base 1 is distributed in a circular array with at least three triangular column holes 11 for temperature measurement. The bottom of the triangular pyramid 2 is inserted into the hole 11 of the triangular prism.

[0013] There are six triangular prism holes 11 distributed in a circular array on the base 1, and the six temperature-measuring triangular cones 2 are respectively inserted into the six triangular prism holes 11. -20°C.

Embodiment 2

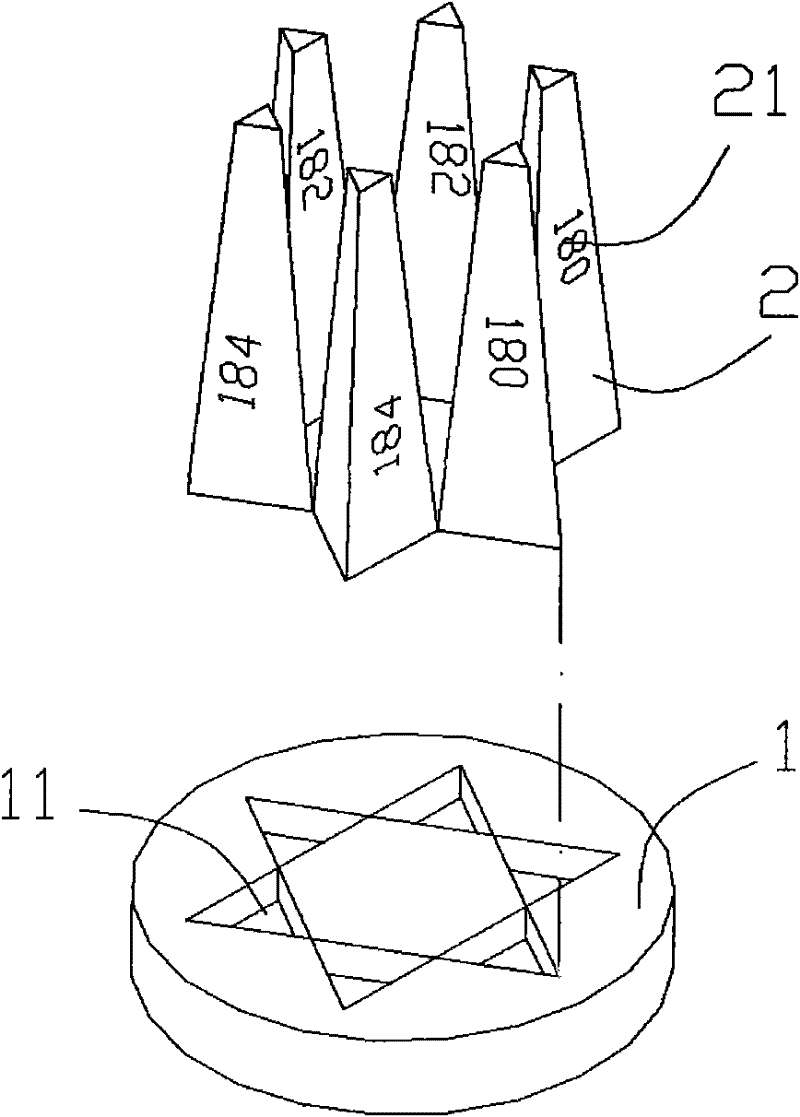

[0014] Embodiment 2, see figure 2 , 3 As shown, six triangular prism holes 11 are distributed in a circular array on the base 1, and the six temperature-measuring triangular cones 2 are respectively inserted into the six triangular prism holes 11. They are the same and are a group of temperature-measuring triangular cones, and the temperature difference between two adjacent groups of temperature-measuring triangular cones is 15-20°C. The rest are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com